©Danfoss A/S (AC-MCI / sw), 2014-03 DKRCC.PS.RP0.A1.02/520H7142 54 DKRCC.PS.RP0.A1.02/520H7142 ©Danfoss A/S (AC-MCI / sw), 2014-03

Manual Superheat controller type EKD 316Manual Superheat controller type EKD 316

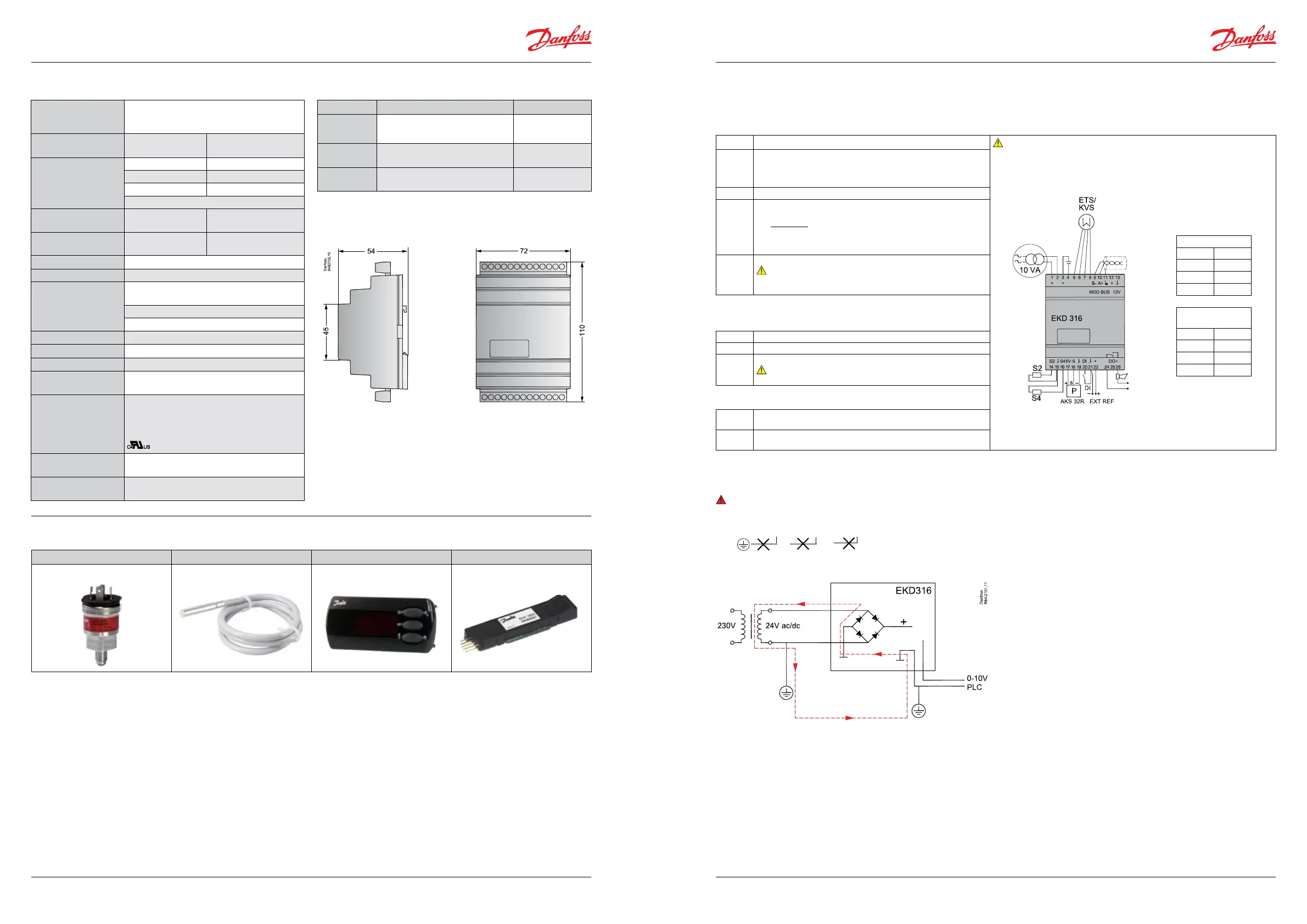

Dimensions

Ordering

Type Function Code no.

EKD 316

superheat controller

(with terminals)

084B8040

EKA 164A

Display

(with MODBUS communication)

084B8563

EKA 183A Programming key 084B8582

Supply voltage

24 V a.c./d.c. +/-15% 50/60 Hz, 10 VA

(the supply voltage is not galvanically

separated from the input and output signals)

Power consumption

Controller

ETS step motor

5 VA

1.3 VA

Input signal

*)Ri: mA: 400 ohm

V: 50 kohm

Current signal * 4-20 mA or 0-20 mA

Voltage signal * 0-10 V or 1-5 V

Pressure transmitter AKS 32R

Digital input from external contact function

Sensor input 2 pcs. Pt 1000 ohm

DI : < 800 ohm → ON

DI : > 30 kohm → OFF

Alarm relay 1 pcs. SPDT

AC-1: 4 A (ohmic)

AC-15: 3 A (inductive)

Step motor output Pulsating 30 - 300 mA

Data communication Mounted with MODBUS data communication

Environments

0 to +55°C, during operations

-40 to +70°C, during transport

20 - 80% Rh, not condensed

No shock inuence/vibrations

Enclosure IP 20

Weight 300 g

Montage DIN rail

Operation

External display type EKA 164A or AK-ST via

data communication and system unit

Approvals

EU Low Voltage Directive and EMC demands re.

CE-marking complied with.

LVD-tested acc. to EN 60730-1 and EN 60730-2-9

EMC-tested acc. to EN50081-1 and EN 50082-2

Battery backup

If battery backup is used, the requirements for

the battery are: 18-24 V d.c. See also page 12.

Max. distance between

controller and valve

30 m

Accessories

Pressure transducer Temperature sensor External display Programming key

AKS 32R, NSK AKS 21, AKS 11 EKA 164A EKA 183A

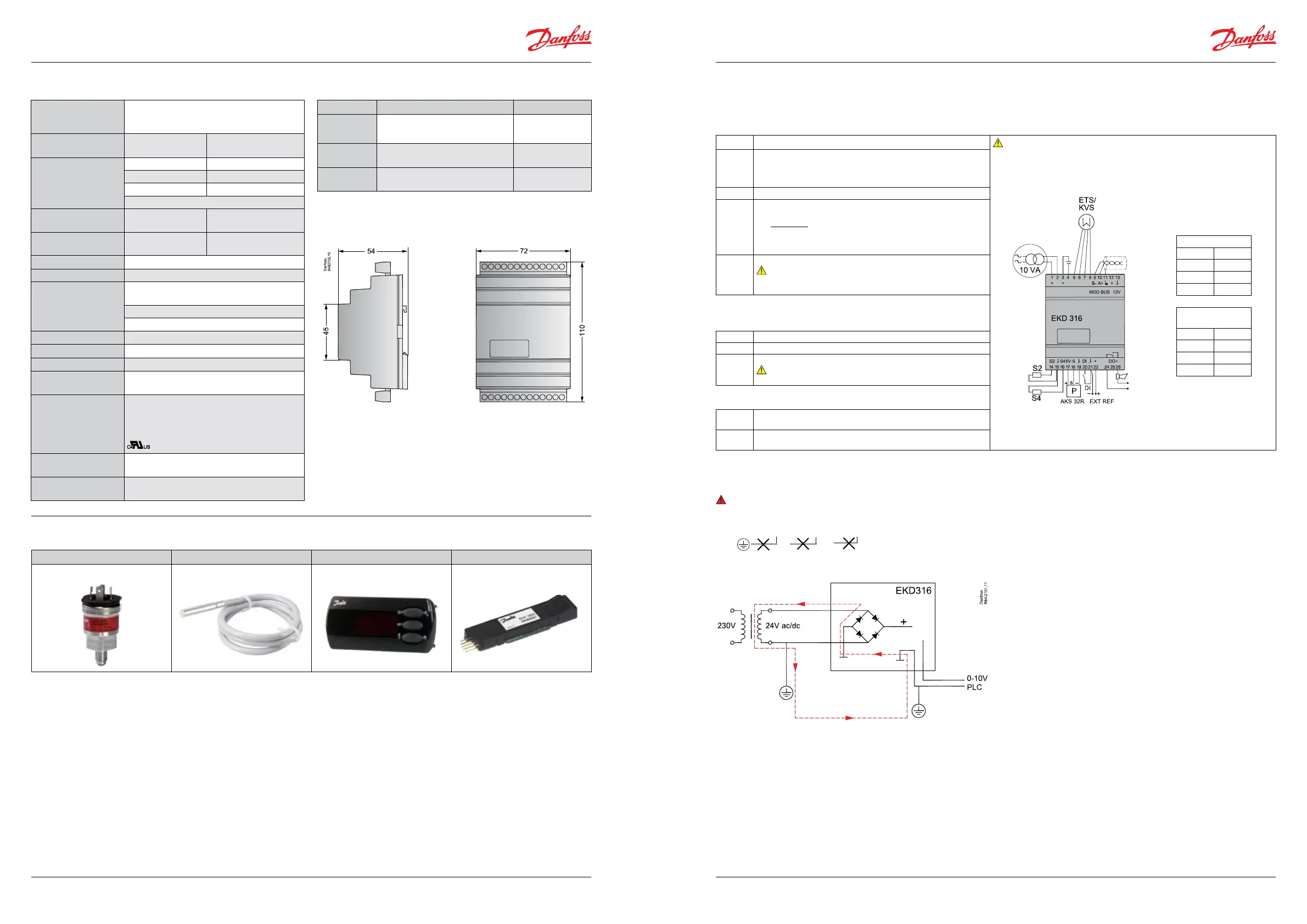

Necessary connections

Terminals:

1-2

Supply voltage 24 V a.c./d.c.

A dedicated transformer must be used.

3-4 Battery (the voltage will close the ETS valve if the

controller loses its supply voltage).

The battery voltage must not be connected from terminals 1

and 2.

Danfoss

24V 18V

Connections

ETS/KVS

White 5

Black 6

Red 7

Green 8

ETS 6/

Saginomiya valves

Orange 5

Yellow 6

Red 7

Black 8

5-8 Supply to stepper motor

9-13

Operation via data communication

EITHER EKA 164A OR System unit + software.

It is important that the installation of the data communication

cable be done correctly.

Cf. separate literature No. RC8AC...

20-21 Switch function for start/stop of regulation.

Note:

If a switch is not connected, terminals 20 and 21 must be short

circuited.

Application-dependent connections

Superheat control

14-15 Pt 1000 sensor at evaporator outlet (S2)

15-16 Pt 1000 sensor for measuring air temperature (S4)

17-19 Pressure transmitter type AKS 32R

Note:

The signal can not be shared with other controllers

Control of the valves opening degree with analog signal

21-22 Current signal or voltage signal from other regulation

(Ext. Ref.)

24-26 Alarm relay

There is connection between 24 and 26 in alarm situa tions.

Connections

Connection to earth will destroy the controller

1,2 3,4 21,22

Class II

Warning

Any external connection with grounding could create a ground

loop through a diode in the rectier bridge which could destroy

the power supply in EKD 316.

Data

Loading...

Loading...