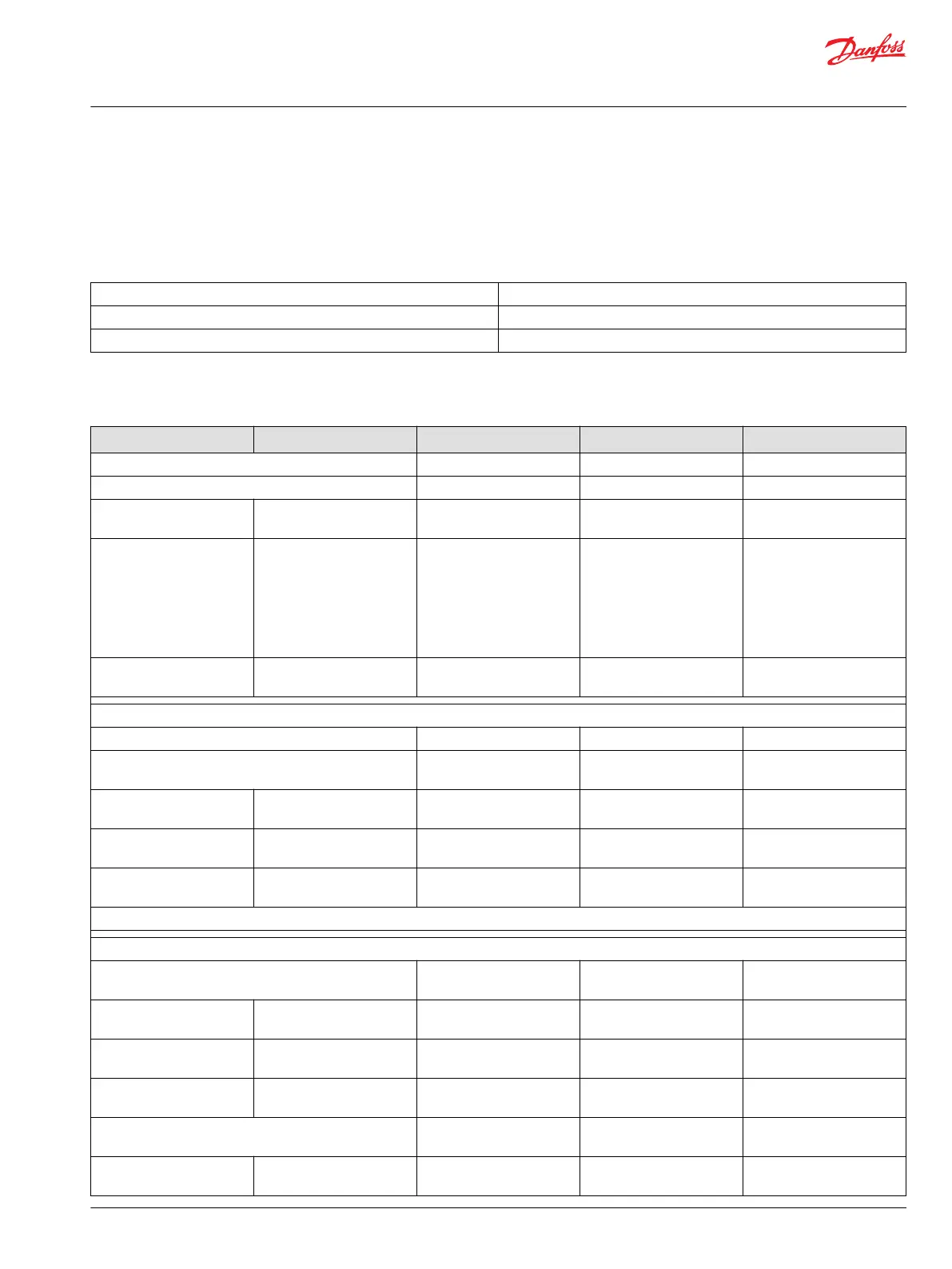

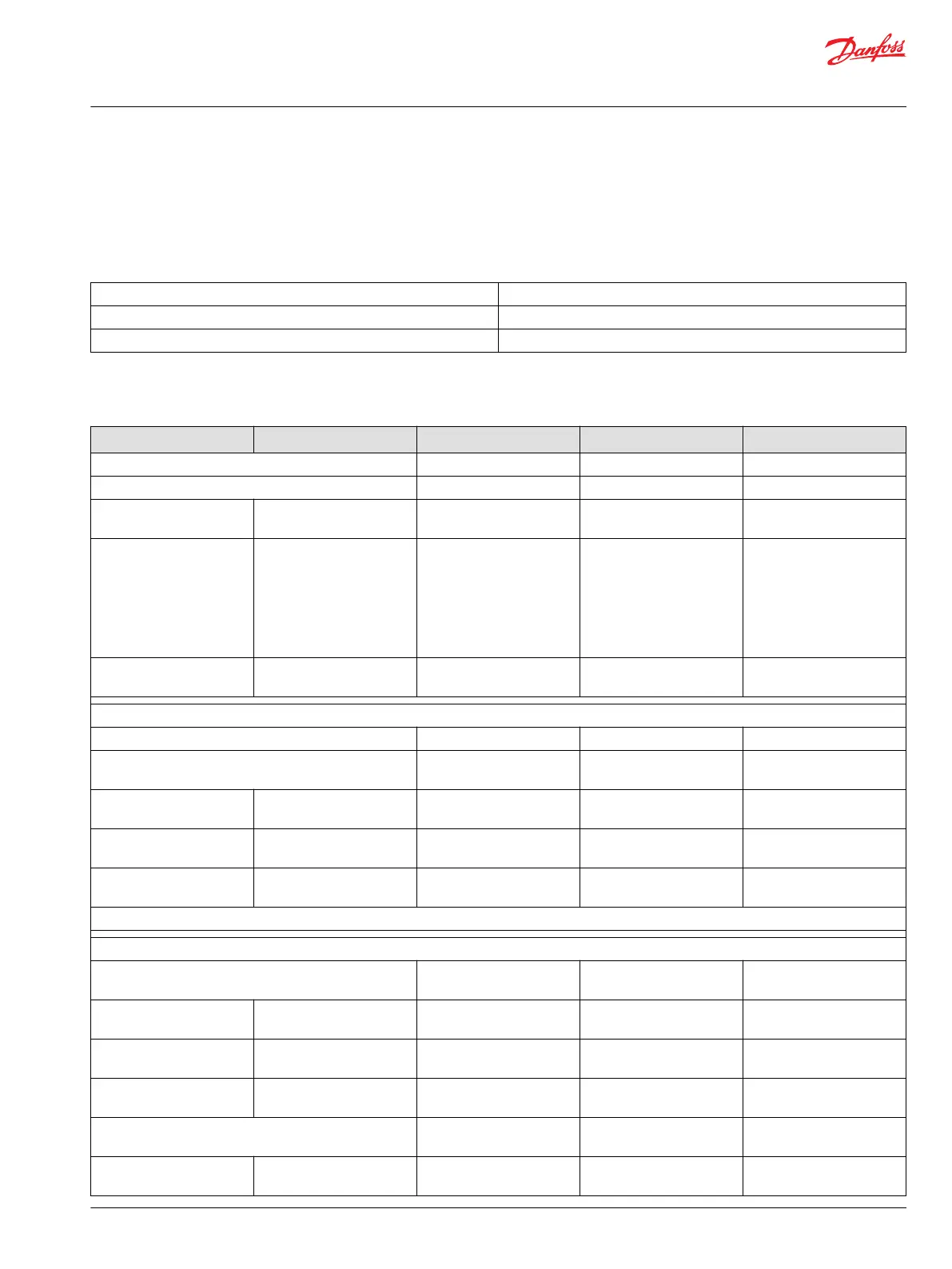

Electric machine installation checklist

Date:

Electric machine and customer information

Customer: Electric machine type (from the rating plate):

Customer reference: Electric machine serial number:

Service reference: Date installed:

N.A = Procedure not applicable PASS = Procedure passed FAIL = Procedure failed

Installation checklist

Approval N.A PASS FAIL

General

Electric machine type is correct ☐ ☐ ☐

Electric machine is

undamaged

☐ ☐ ☐

Insulation resistance check

(Reference value of 150 MΩ

should not be exceeded at

reference ambient

temperature 25°C (measured

with 500 V

DC

/ 1 min

Megger))

>150MΩ ☐ ☐ ☐

Environmental conditions as

specified (see data sheet)

☐ ☐ ☐

Mechanical installation

Supporting structure as required ☐ ☐ ☐

Shaft alignment as specified (see chapter Shaft alignment

and load).

☐ ☐ ☐

D-end attachment bolt

tightening torque

40 Nm ☐ ☐ ☐

N-end attachment bolt

tightening torque

30 Nm ☐ ☐ ☐

Cooling circuit connected

and coolant flowing

☐ ☐ ☐

Used coolant:

Power connections

Cable gland assembly as specified (cable gland to cables)

with correct cable diameter

☐ ☐ ☐

Cable lug air cap (to metallic

structures)

≥10 mm ☐ ☐ ☐

Cable gland tightening

torque (to the box)

15 Nm ☐ ☐ ☐

Cable lug tightening torque

(to the busbar)

13 Nm ☐ ☐ ☐

The phase connections order is correct (U, V, W -> L1, L2,

L3)

☐ ☐ ☐

Connection box cover bolts

tightening torque

4 Nm ☐ ☐ ☐

User Guide

EM-PMI375

Storage, installation and maintenance checklists

©

Danfoss | November 2021 BC265856307805en-000202 | 77

Loading...

Loading...