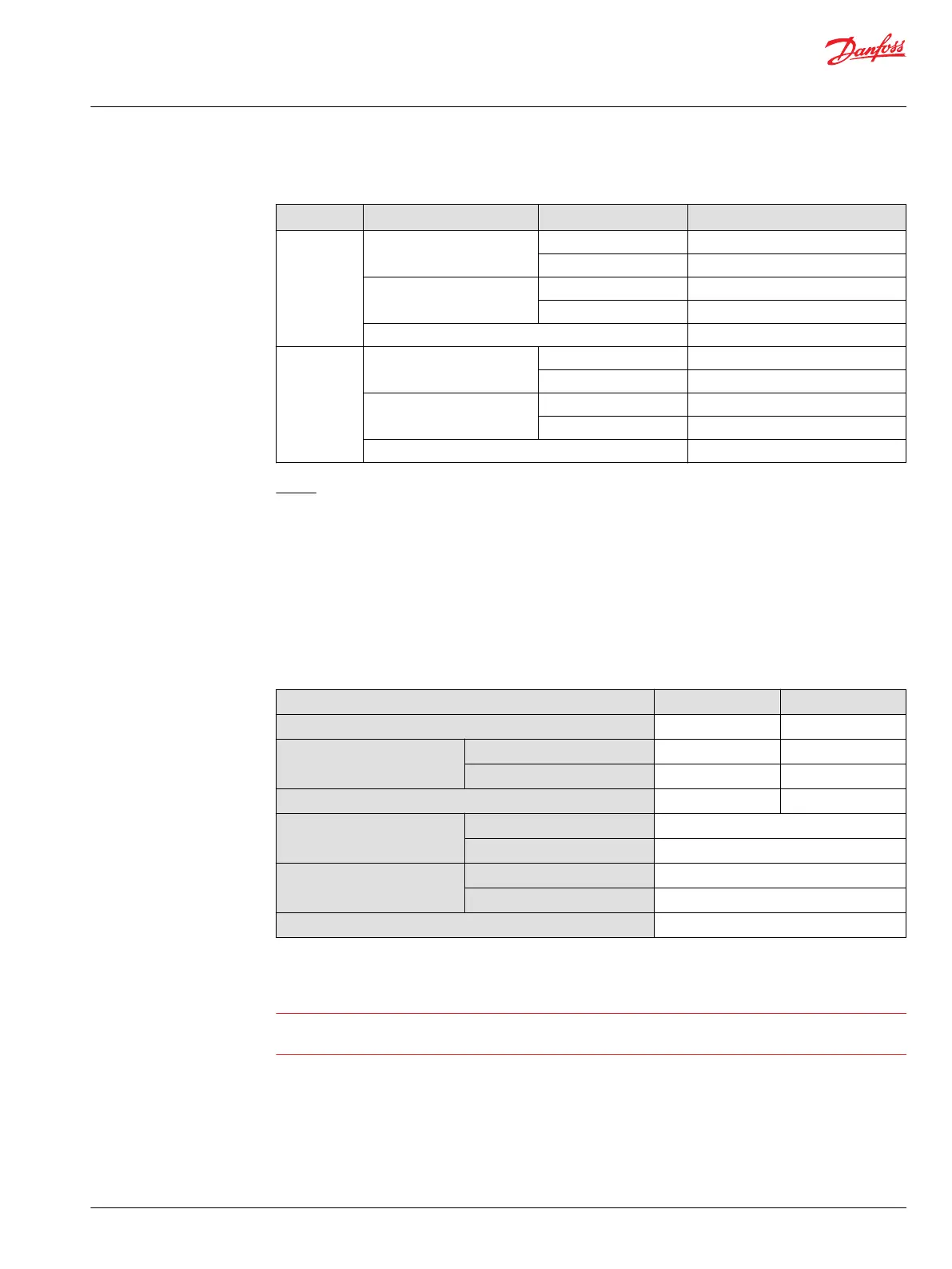

Formulas to calculate start and end input command

Control type Input command (mA)

% displacement

All sizes (mA)

M1

Start input command

from 0%

480 ± 10

from x % min.

(V

gx

/V

gmax

) x 1110 + 480

End input command

at 100 %

1590 ± 130

at y % max.

(V

gy

/V

gmax

) x 1110 + 480

Max. allowed current 1800

M2

Start input command

from 0%

240 ± 5

from x % min.

(V

gx

/V

gmax

) x 570 + 240

End input command

at 100 %

810 ± 67

at y % max.

(V

gy

/V

gmax

) x 570 + 240

Max. allowed current 920

Where:

V

gmax

Maximum, theoretic possible motor displacement per revision (cm

3

/rev)

V

gx

Minimum displacement setting of desired unit (cm

3

/rev)

V

gy

Maximum displacement setting of desired unit (cm

3

/rev)

x Minimum displacement (%)

y Maximum displacement (%)

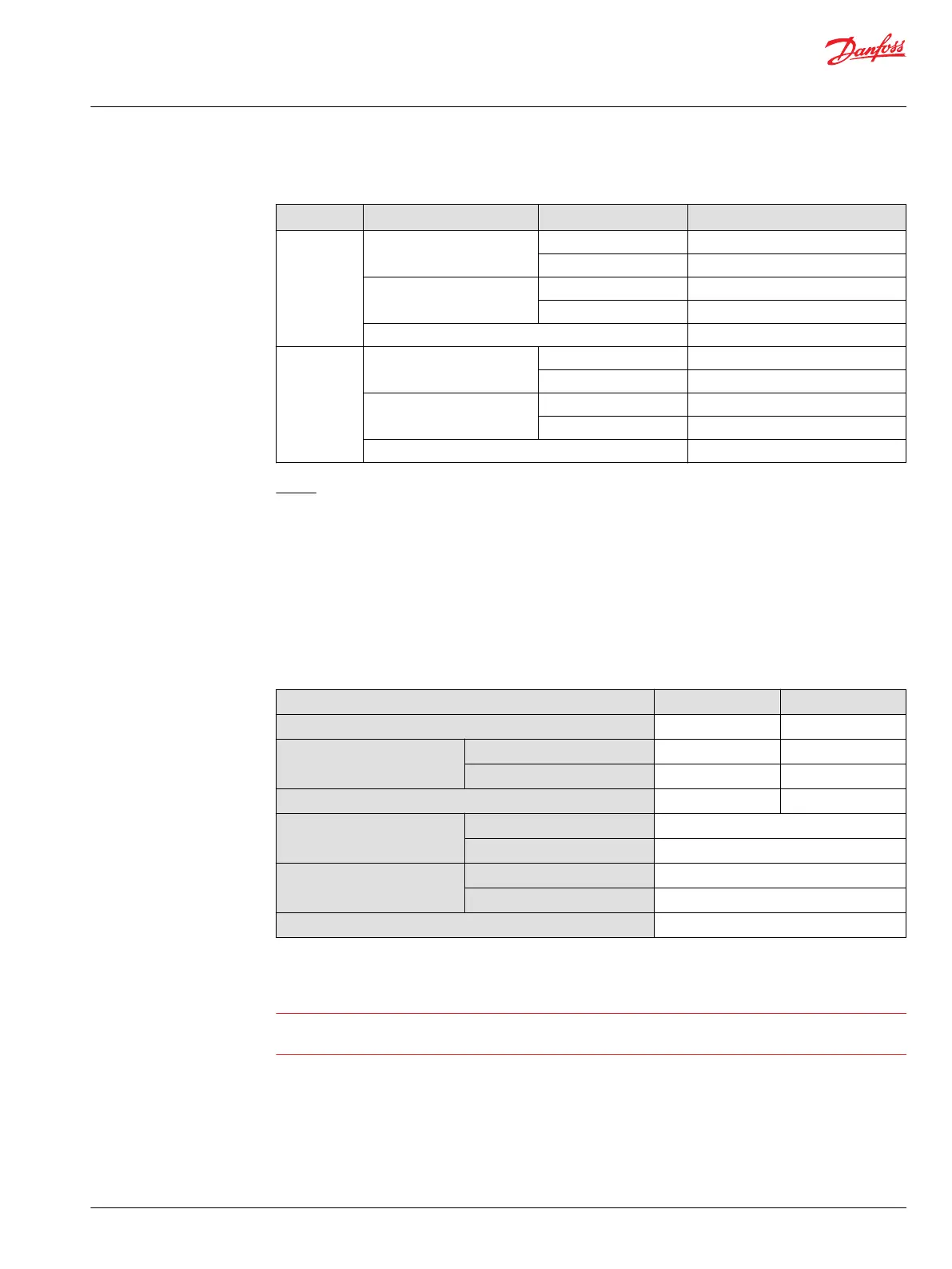

Proportional solenoid data C1

Description 12 V 24 V

Maximum current

1800 mA 920 mA

Nominal coil resistance @ 20 °C [68 °F]

3.66 Ω 14.20 Ω

@ 80 °C [176 °F]

4.52 Ω 17.52 Ω

Inductance

33 mH 140 mH

PWM Range

70-200 Hz

Frequency (preferred)

*

100 Hz

IP Rating IEC 60 529

IP 67

DIN 40 050, part 9

IP 69K with mating connector

Connector color

Black

*

PWM signal required for optimum control performance.

Warning

Zero degree capability results in a high risk of overspeed and drops in efficiency if the motor operates

between 0–20% displacement.

Technical Information

H1 Bent Axis Variable Displacement Motors, Size 060/080/110/160/210/250

Controls – nomenclature, description

©

Danfoss | December 2016 11037153 | BC00000043en-US1103 | 49

Loading...

Loading...