Remote pressure compensated controls

The remote PC control is a two-stage control that allows multiple PC settings. Remote PC controls are

commonly used in applications requiring low and high pressure PC operation.

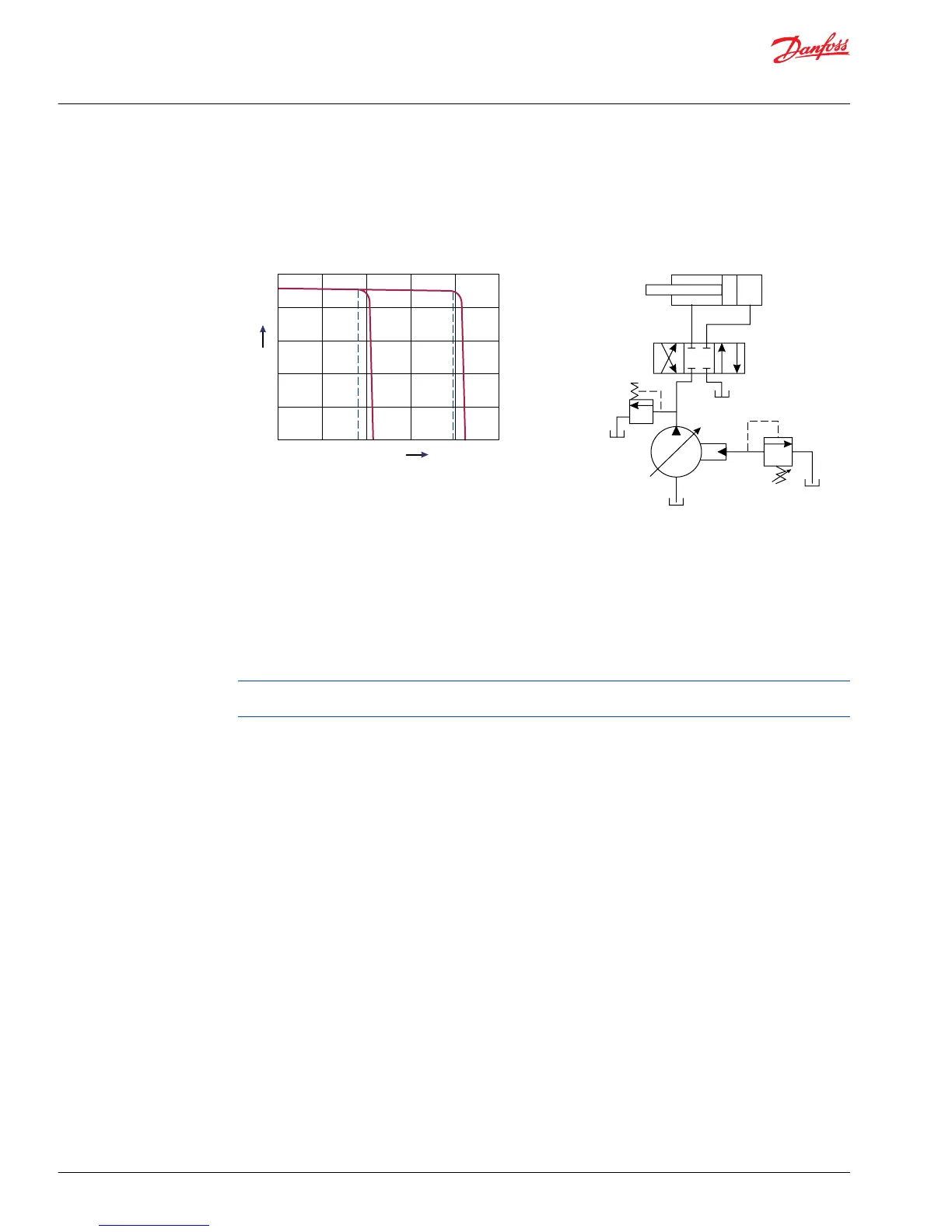

Typical operating curve

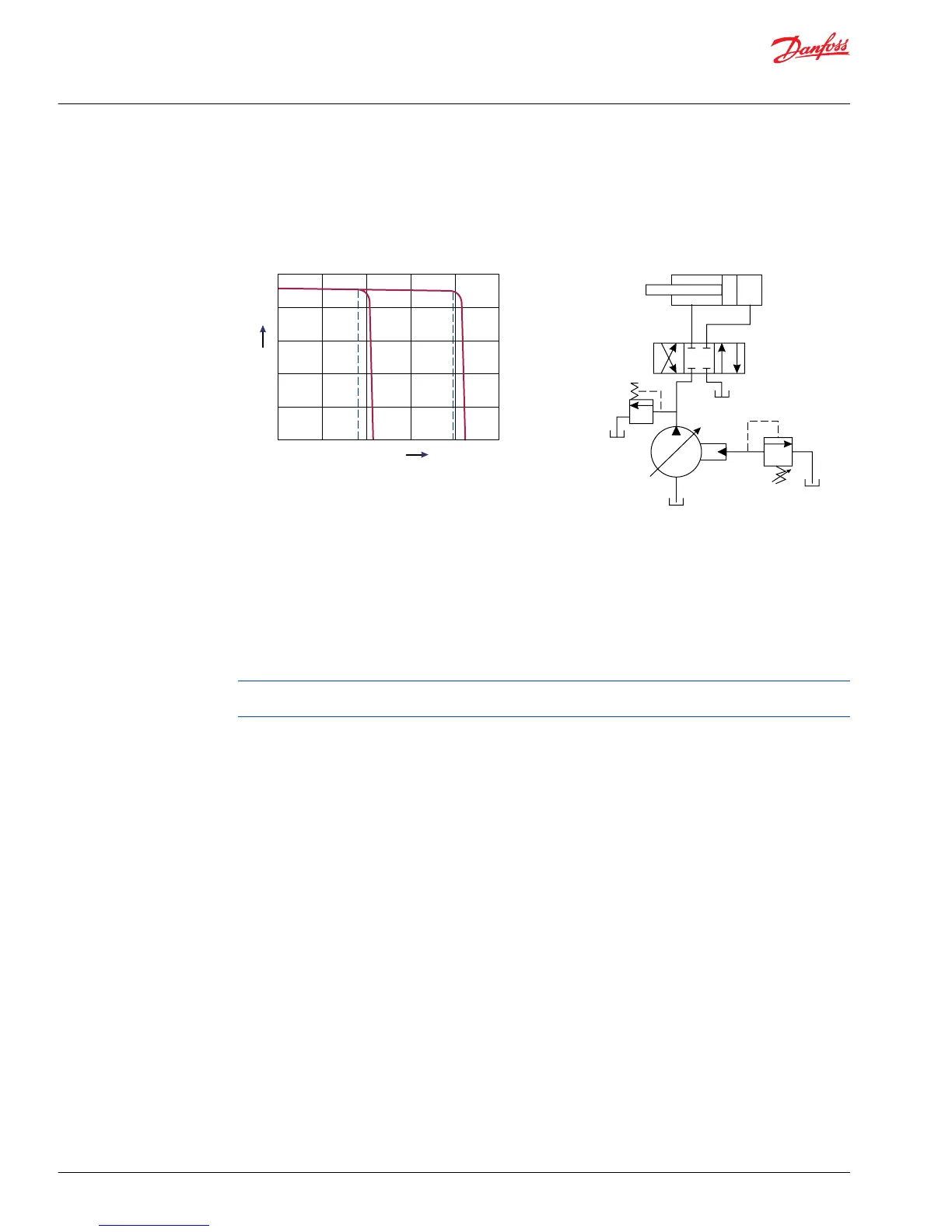

The remote PC control uses a pilot line connected to an external hydraulic valve. The external valve

changes pressure in the pilot line, causing the PC control to operate at a lower pressure. When the pilot

line is vented to reservoir, the pump maintains pressure at the load sense setting.

When pilot flow is blocked, the pump maintains pressure at the PC setting. An on-off solenoid valve can

be used in the pilot line to create a low-pressure standby mode. A proportional solenoid valve, coupled

with a microprocessor control, can produce an infinite range of operating pressures between the low

pressure standby setting and the PC setting.

Size the external valve and plumbing for a pilot flow of 3.8 l/min [1 US gal/min]. For additional system

protection, install a relief valve in the pump outlet line.

Remote pressure compensated system characteristics:

•

Constant pressure and variable flow

•

High or low pressure standby mode when flow is not needed

•

System flow adjusts to meet system requirements

•

Single pump can provide flow to multiple work functions

•

Quick response to system flow and pressure requirements

Typical applications for remote pressure compensated systems:

•

Modulating fan drives

•

Anti-stall control with engine speed feedback

•

Front wheel assist

•

Road rollers

•

Combine harvesters

•

Wood chippers

Service Manual

PVG 16 and 32 Service Assembly/Disassembly Guide

General information

10 |

©

Danfoss | November 2017 L1104530 | AX00000133en-US0106

Loading...

Loading...