1.2 Purpose of the Manual

This manual provides detailed information for the instal-

lation and start up of the frequency converter.

Chapter 3 Installation provides requirements for mechanical

and electrical installation, including:

•

Input

•

Motor

•

Control wiring

•

Serial communications wiring

•

Control terminal functions

VLT

®

is a registered trademark.

1.3 Product Overview

A frequency converter is an electronic motor controller

that converts DC into a variable AC waveform output. The

frequency and voltage of the output are regulated to

control the motor speed or torque. The frequency

converter can vary the speed of the motor in response to

remote commands from external controllers.

The frequency converter offers many control, monitoring

and efficiency functions such as

•

monitoring the system and motor status

•

Issuing warnings or alarms for fault conditions

•

starting and stopping the motor

•

optimising energy efficiency

Operation and monitoring functions are available as status

indications to an outside control system or serial communi-

cation network.

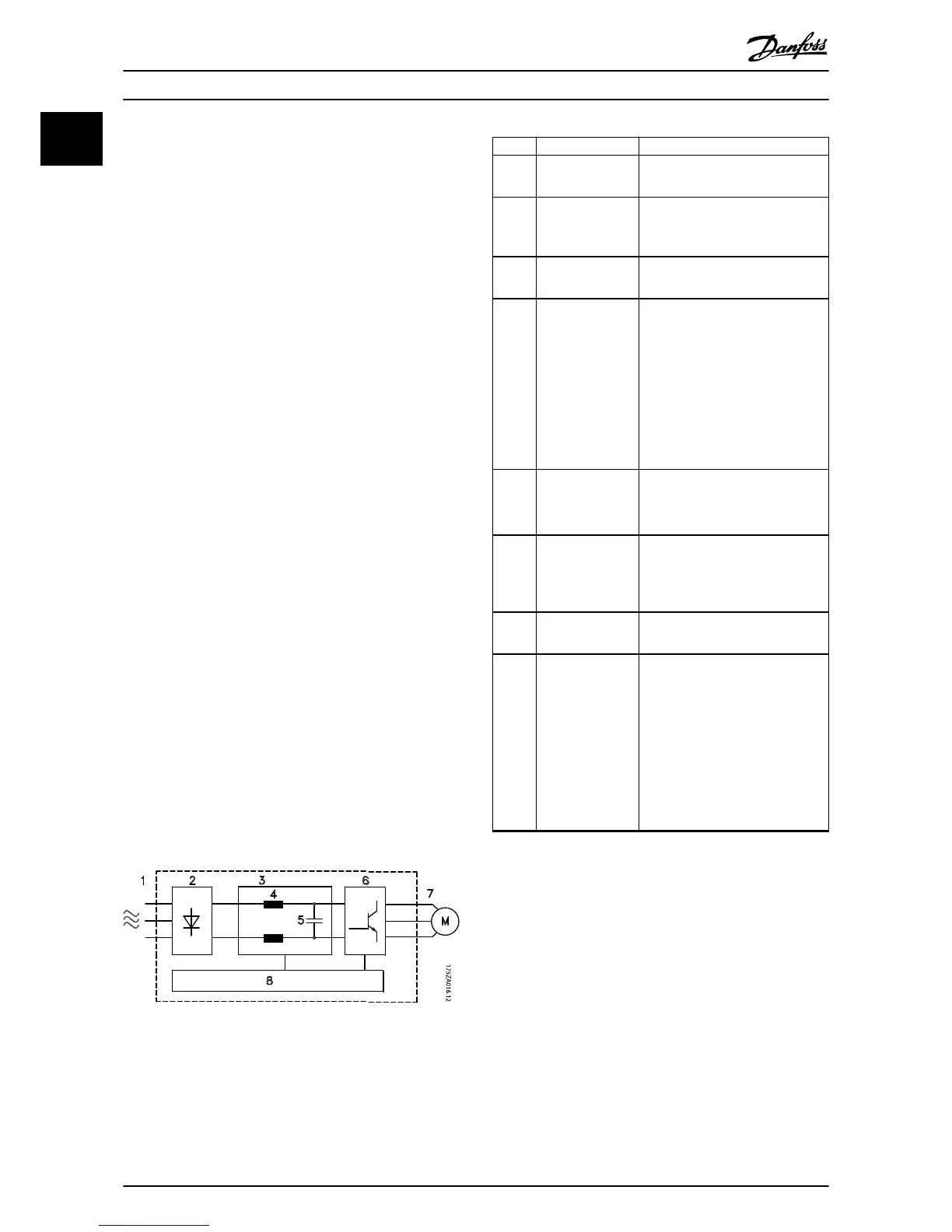

1.4

Internal Controller Functions

Illustration 1.3 is a block diagram of the frequency

converter's internal components.

Illustration 1.3 Frequency Converter Block Diagram

Area Title Functions

1 Mains input

•

3-phase AC mains supply to the

frequency converter

2 Rectifier

•

The rectifier bridge converts the

AC input to DC current to

supply inverter power.

3 DC-bus

•

Intermediate DC-bus circuit

handles the DC current.

4 DC reactors

•

Filter the intermediate DC circuit

voltage.

•

Prove line transient protection.

•

Reduce RMS current.

•

Raise the power factor reflected

back to the line.

•

Reduce harmonics on the AC

input.

5 Capacitor bank

•

Stores the DC power.

•

Provides ride-through protection

for short power losses.

6 Inverter

•

Converts the DC into a

controlled PWM AC waveform

for a controlled variable output

to the motor.

7 Output to motor

•

Regulated 3-phase output

power to the motor

8 Control circuitry

•

Input power, internal processing,

output, and motor current are

monitored to provide efficient

operation and control.

•

User interface and external

commands are monitored and

performed.

•

Status output and control can

be provided.

Table 1.2 Legend to Illustration 1.3

Introduction Danfoss Turbocor

4 Danfoss A/S © 01/2015 All rights reserved. MG35Q202

1

1

Loading...

Loading...