53

www.Daniel.com

USER MANUAL

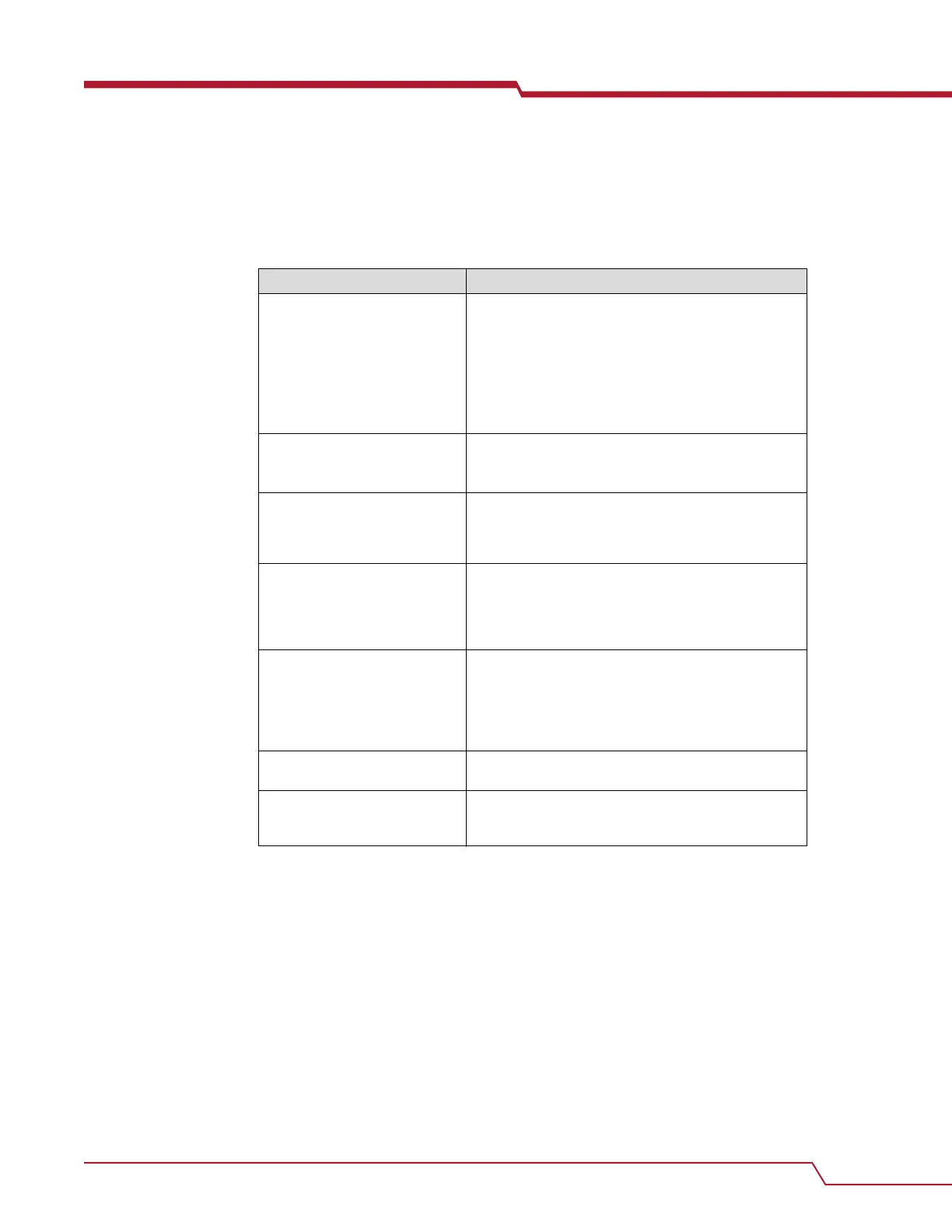

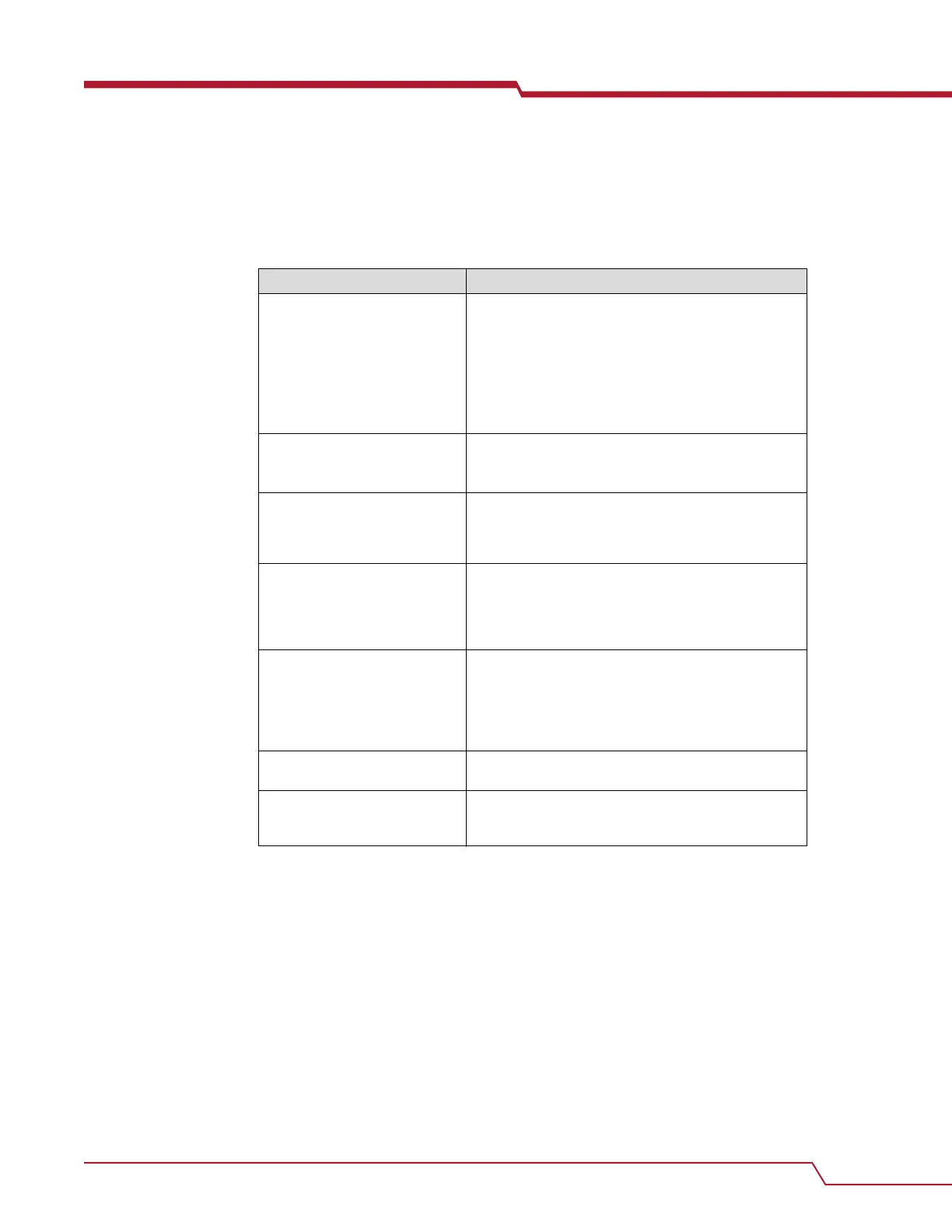

9.5 Planned maintenance tasks

Table 9-2: Planned maintenance tasks

Task Recommended action

Inspect Implement a periodic inspection program to ensure all parts

are free from damage during its use due to process, ambient

or other abnormal conditions.

• Internal components: cylinder, piston, spring, cylinder

head, seat retainer

• Control valve body

• Bolting

Clean Use a non-toxic metal cleaning solvent.

Do not use common petrochemical solvents like Benzene,

Toluene or Xylene as they can pose potential health hazards.

Monitor corrosion / erosion / wear A careful review of the control valve proving history, such as

control valve factor control charts, can reveal potential

problems bearing drag due to wear or increased internal

cross-sectional area due to erosion.

Part (seal) replacement Visual inspection of the O-rings is recommended once a year

and replacement of the O-rings is recommended at least

once every five years. Follow internal procedures for part

replacement. Do not twist or overstretch the O-ring during

assembly.

Corrosion monitoring Daniel recommends visually inspecting the control valve for

corrosion in the internal components at least once a year.

Follow internal procedures for corrosion. The valve was

designed without corrosion allowance. Periodically inspect

the valve's metal parts for corrosion and erosion, and inspect

the seals and O-rings for wear and chemical damage.

Lubricant information High-viscosity silicone oil with a temperature range of -65° F

to 400° F (-54° C to 204° C).

Proper lubrication procedure Lubricate the entire surface of the O-ring before installation

with a thin layer of high-viscosity silicone oil. Remove excess

lubricant.

Planned maintenance User manual

November 2020 P/N 3-9008-553

62 Daniel Series 700 Control Valve

Loading...

Loading...