54

www.Daniel.com

MODEL 700 CONTROL VALVE

10

10.1

Corrective maintenance

Control valve troubleshooting

Use the table below to troubleshoot the control valve. Contact the nearest Daniel Flow

services center for assistance with repairs of Daniel products. It is important that servicing

be performed by trained and qualified service personnel.

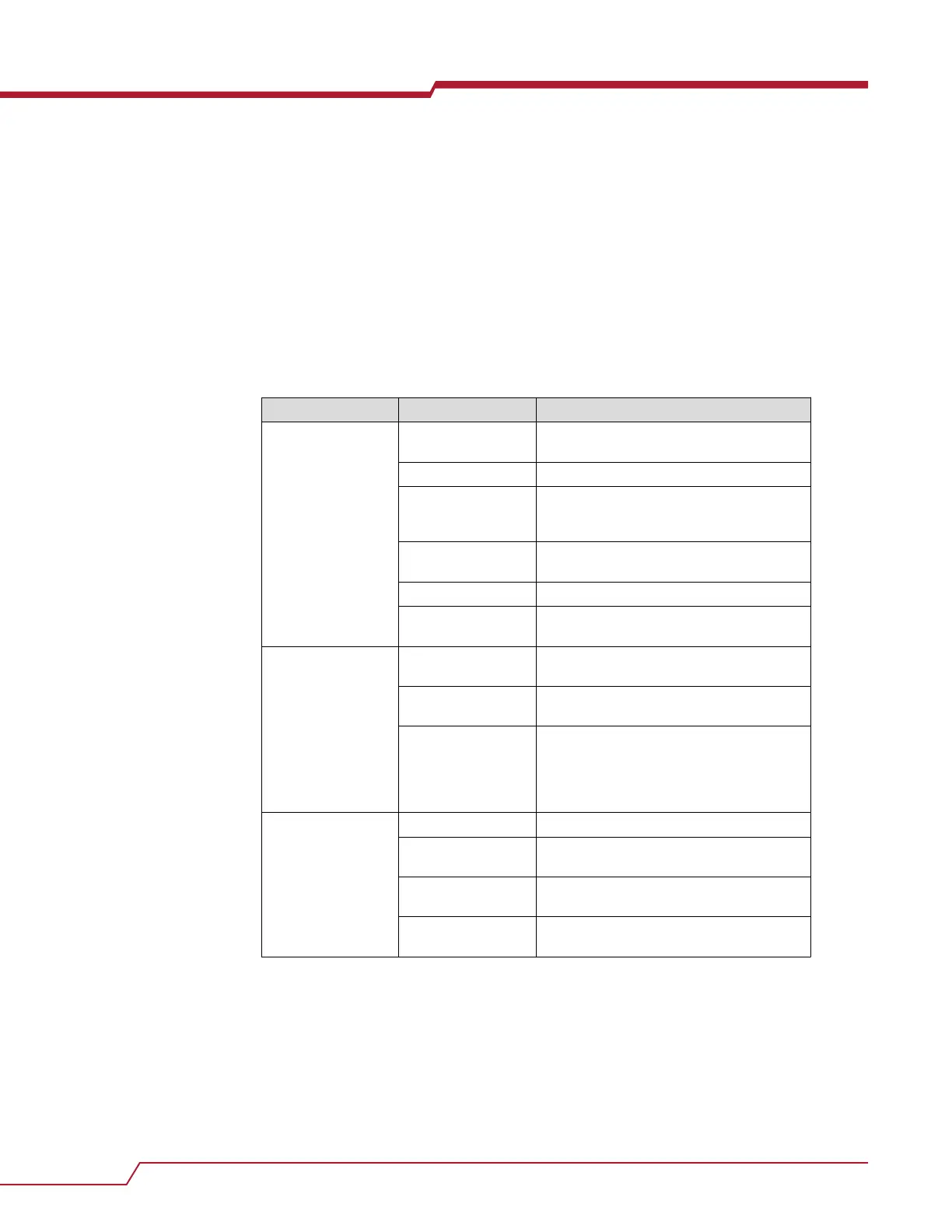

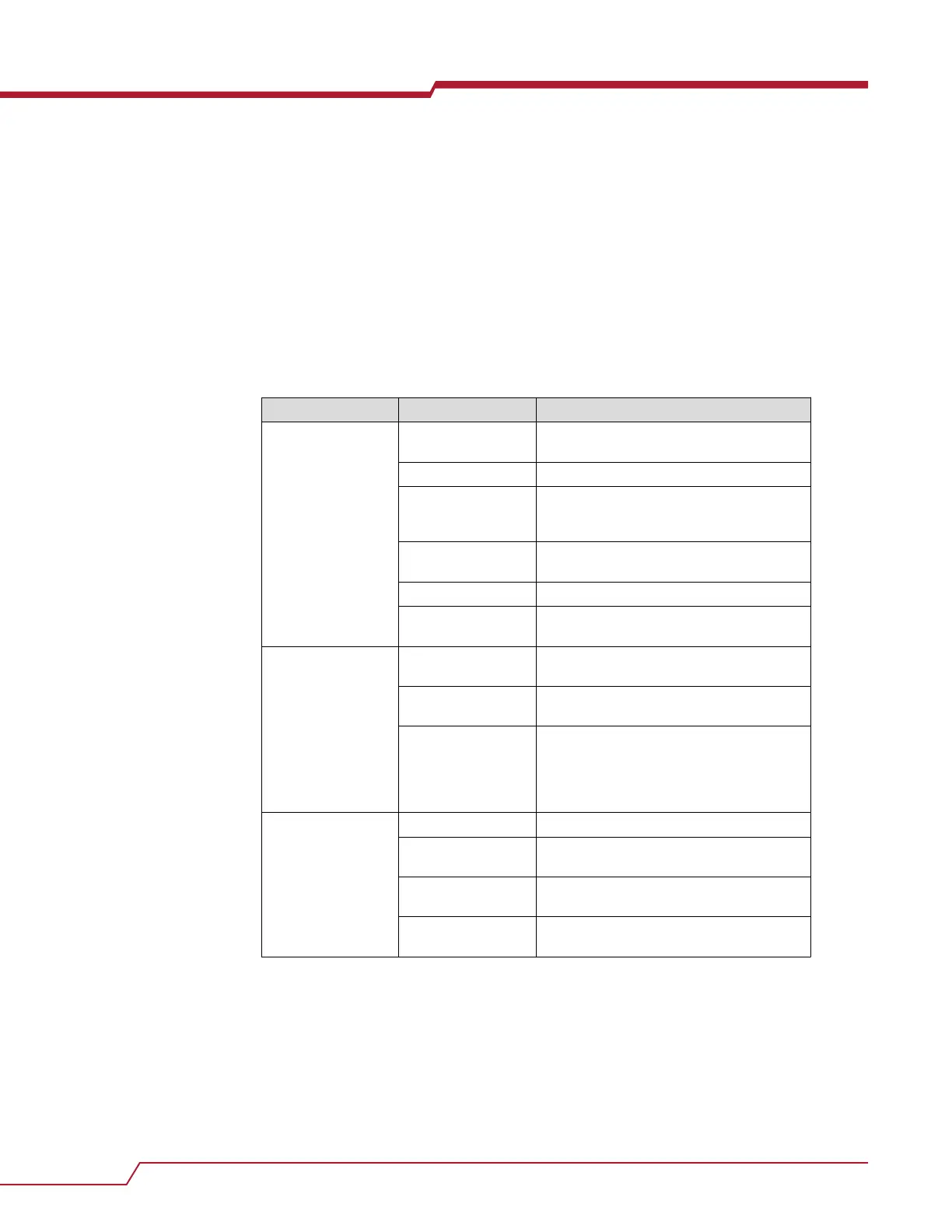

Table 10-1: Troubleshooting issues of model 700 Control Valve

Condition Probable cause Correction

(1)

Valve will not open Upstream valve is

closed

Open upstream valve.

Pump is not operating Start pump and check for cavitation.

Downstream valve is

closed

Open downstream valve. (Check coupler on

bottom loading units and internal valve in

truck.)

Insufficient pressure Check pump. Check bypass and strainer located

in line.

Clogged strainer Clean strainer.

Swollen O-rings Disassemble valve and replace O-rings. Check

compatibility of O-rings with product.

Valve opens too slowly Valve inlet pressure

below normal

Check strainer and pump for obstruction.

Swollen O-rings Disassemble valve and replace O-rings. Check

compatibility of O-rings with product.

Check "X" port

sensitivity control

needle valve position

(maybe closed too

much)

Open sensitivity control needle valve.

Valve will not close off

tightly

Bent indicator stem Replace indicator.

Foreign material in

main valve piston seat

Disassemble valve and inspect piston.

Swollen O-rings Disassemble valve and replace O-rings. Check

compatibility of O-rings with product.

Piston or seat O-ring

cut or defective

Disassemble valve and replace if necessary.

(1) Refer to Mechanical disassembly procedures.

User manual Corrective maintenance

P/N 3-9008-553 November 2020

User manual 63

Loading...

Loading...