16

File Management Icon

Press this icon in order to save, recall or delete drill les. The XPS-16+ will store 100

custom dened drill les. In the event that more storage is necessary, the X-Loader

software supplied with your XPS-16+ will allow drills les to be sent and retrieved via

your computer.

Note: File #1 DAREX FILE is factory created and is the default le to start with

when creating new drill les.

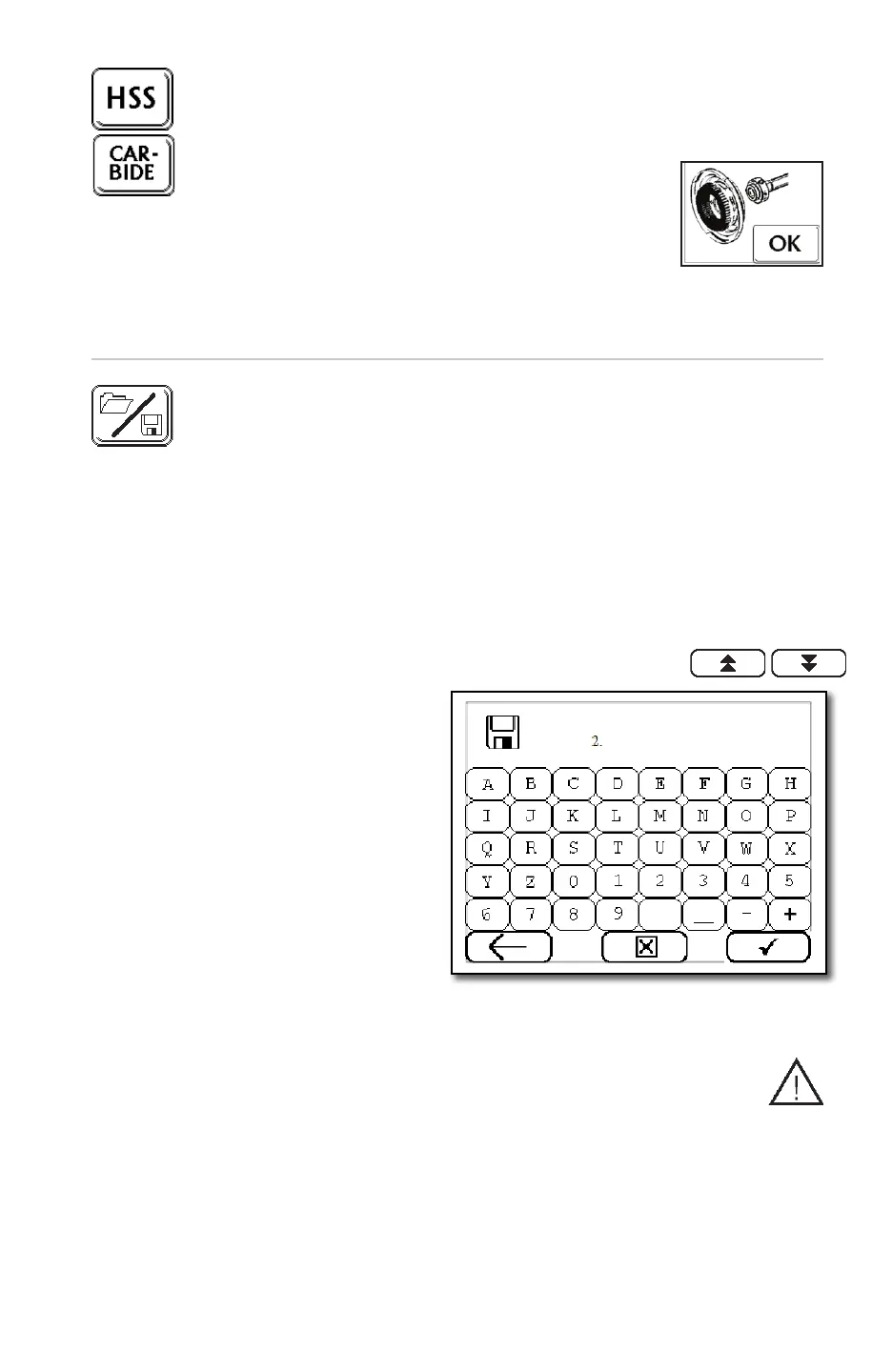

• Press the File Management Icon – a list of the drill les existing on the XPS-16+

will appear.

• Press the [DOWN] or [UP] to move the selector arrow to an open position.

Note: page up or down arrows will move selector much faster.

• Press the [SAVE] icon to

initiate a new program. A

keyboard will appear. Using

a maximum of 20 characters,

name your program.

• Press the [CHECK] to

return to the Main Operating

Screen. Notice the le name

now appears on the File

Management icon.

• In the event a program is no

longer necessary, use the arrow

keys to move the selector to

the desired program and press the [DELETE] icon. Press the [CHECK] icon to

remove the program.

Note: In the event a program is over-written, a warning will show on the

display. Pressing the [CHECK] will allow the changes to the program and

pressing the [X] will not allow the changes.

Note: A drill le can be locked to avoid being edited or removed. In order to do so,

start the drill le name with a plus [+] symbol. Example: +135facet

To delete or modify a locked drill le, a password is needed. Please contact your

Darex Representative for customer service.

Drill Material Icon

Pressing this icon will prompt the user to execute a grind wheel change, CBN for HSS/

Cobalt and Diamond for carbide drills. Changing to the correct icon internally adjusts

some of the grind stock removal and grind speed rates.

Tip: Even though the XPS-16+ prompts the operator for a grind

wheel change, the machine does not know if that grind wheel

change has been executed. Using the incorrect grind wheel will

have a negative effect on grind wheel life.

Tip: After a grind wheel change, it may be necessary to make an offset adjustment to

the grind wheel face and/or the grind wheel edge. Those adjustments will be covered in

the Wheel Position Adjustment portion of the User Guide.

Loading...

Loading...