55

glass are not unusual at this point. It is likely that more refrigerant will be required to complete the

charging procedure.

Finish charging circuit 1 by slowly opening the valve on the refrigerant manifold set to meter liquid

refrigerant into the low side of the system. Use a liquid charging adapter to prevent liquid refrigerant

from entering the compressor.

NOTICE: Charging to a full liquid line sight glass should never be the sole

means of determining the correct refrigerant charge. Other parameters such

as superheat, suction pressure, head pressure, subcooling and ambient

temperature are also important factors. A system charged to a clear sight

glass is often overcharged.

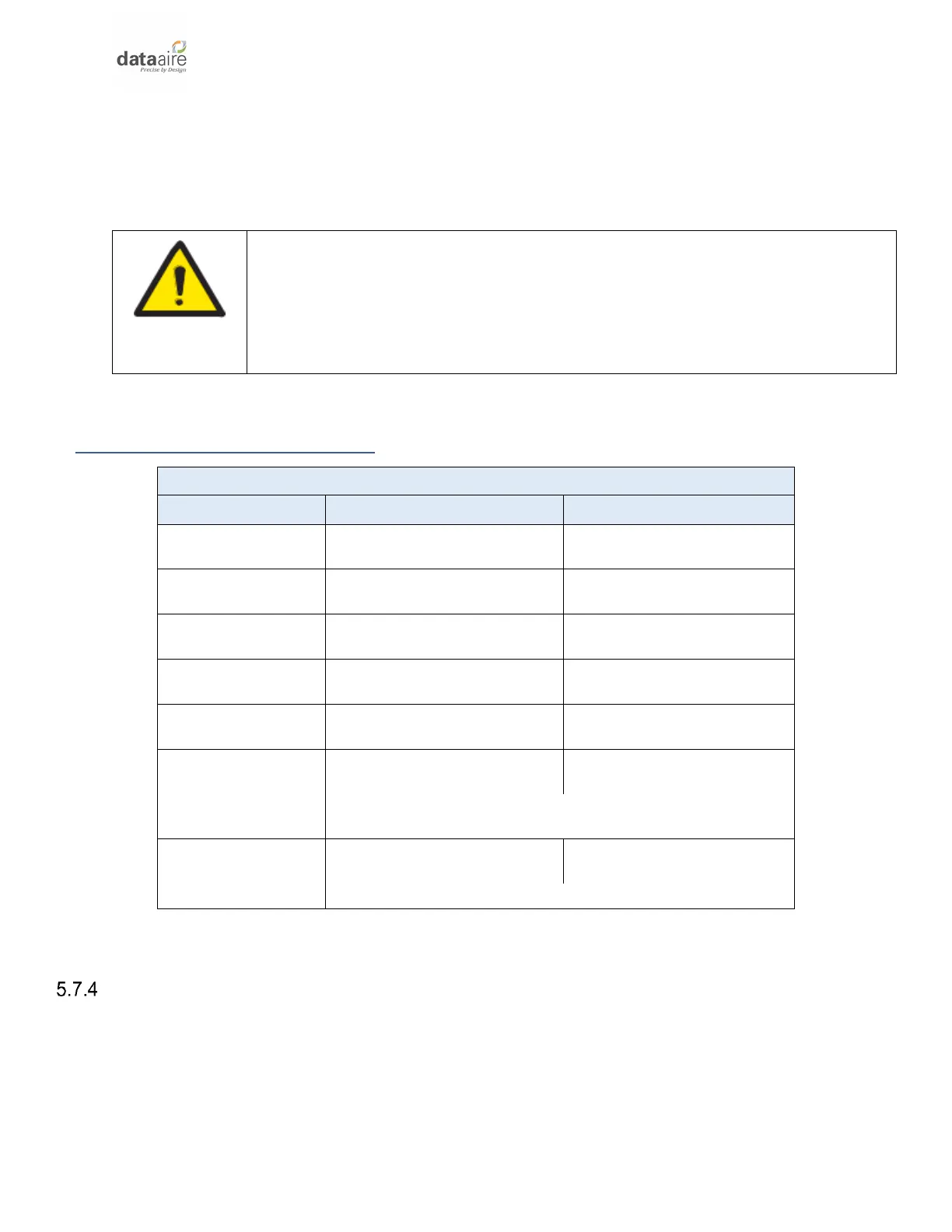

Adjust the refrigerant charge to the subcooling value shown in the table below and the sight glass has

sparse bubbles. The unit should be allowed to stabilize for 15 to 20 minutes to verify key measurements

in Table 20 Refrigerant Charge Values below.

Table 20 Refrigerant Charge Values

322 PSIG (2220 kPa)

minimum

199 PSIG (1372 kPa)

minimum

290 to 390 PSIG

(2000 to 2688 kPa)

245 to 285 PSIG

(1689 to 1965 kPa)

85 to 100°F

(29.4 to 37.8°C)

106 to 115°F

(41.1 to 46.1°C)

103 to 130 PSIG

(710 to 896 kPa)

53 to 70 PSIG

(365 to 483 kPa)

Suction Saturated

Temperature

33 to 45°F

(0.56 to 7.2°C)

33 to 45°F

(0.56 to 7.2°C)

8 to 15°F

(-13.3 to -9.4°C)

8 to 10°F

(-13.3 to -12.2°C)

Differential Temperature - Depending on ambient conditions, at

compressor’s maximum speed

8 to 18°F

(-13.3 to -7.8°C)

8 to 15°F

(-13.3 to -9.4°C)

Measure the superheat at the compressor suction line at least 6 inches (152 mm) away from the

compressor. Measure subcooling at the liquid line.

Additional Oil

When charging is complete, add the correct amount of oil to each circuit. In installations with good oil

return and line runs up to 50 ft (15 m), no additional oil is required. If installation lines exceed 50 ft (15

m), additional oil needs to be added. 1 or 2% of the total system refrigerant charge (in weight) can be

used to roughly define the required oil top-up quantity.

Loading...

Loading...