9

If equipment is stored for longer than 30 days special precautions must be taken to avoid coil dam-

age. All coils should be charged and sealed with a low pressure (less the 25 PSIG) inert gas, such

nitrogen. This prevents contaminants from entering the coils. When the seal is broken at installa-

tion, the rush of escaping gas verifi es the coil is still leak free. If coils are not charged and sealed,

condensation mixes with air pollutants forming a weak acid and over time can cause pinhole leaks

to develop in coil tubes.

When equipment is installed after storage, caution should be taken to inspect and replace, if re-

quired, rubber hoses and belts. All moving parts, such as blowers and motors, should be hand

tested to ensure they are free and clear prior to start-up. Finally, verify that all lubrication is fresh

and full.

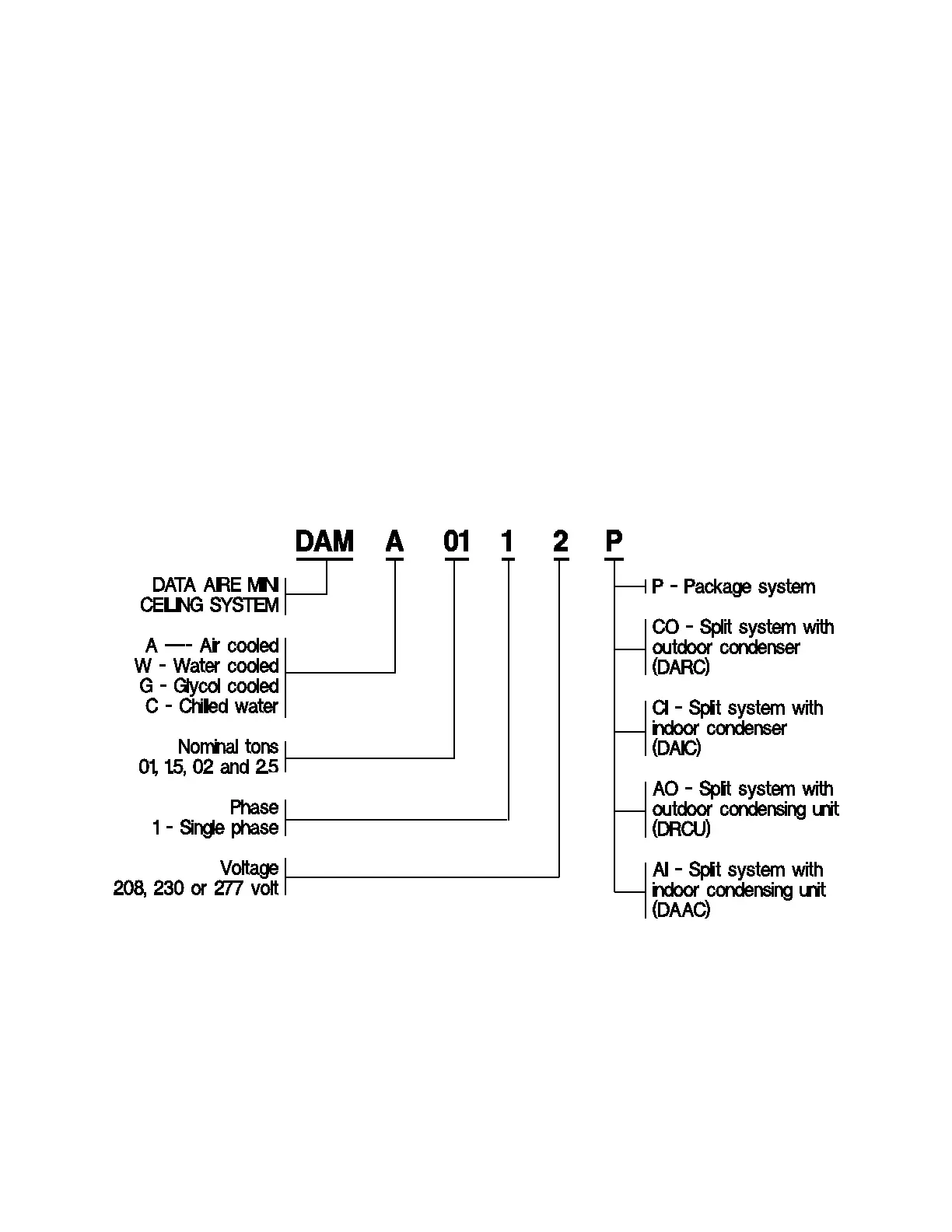

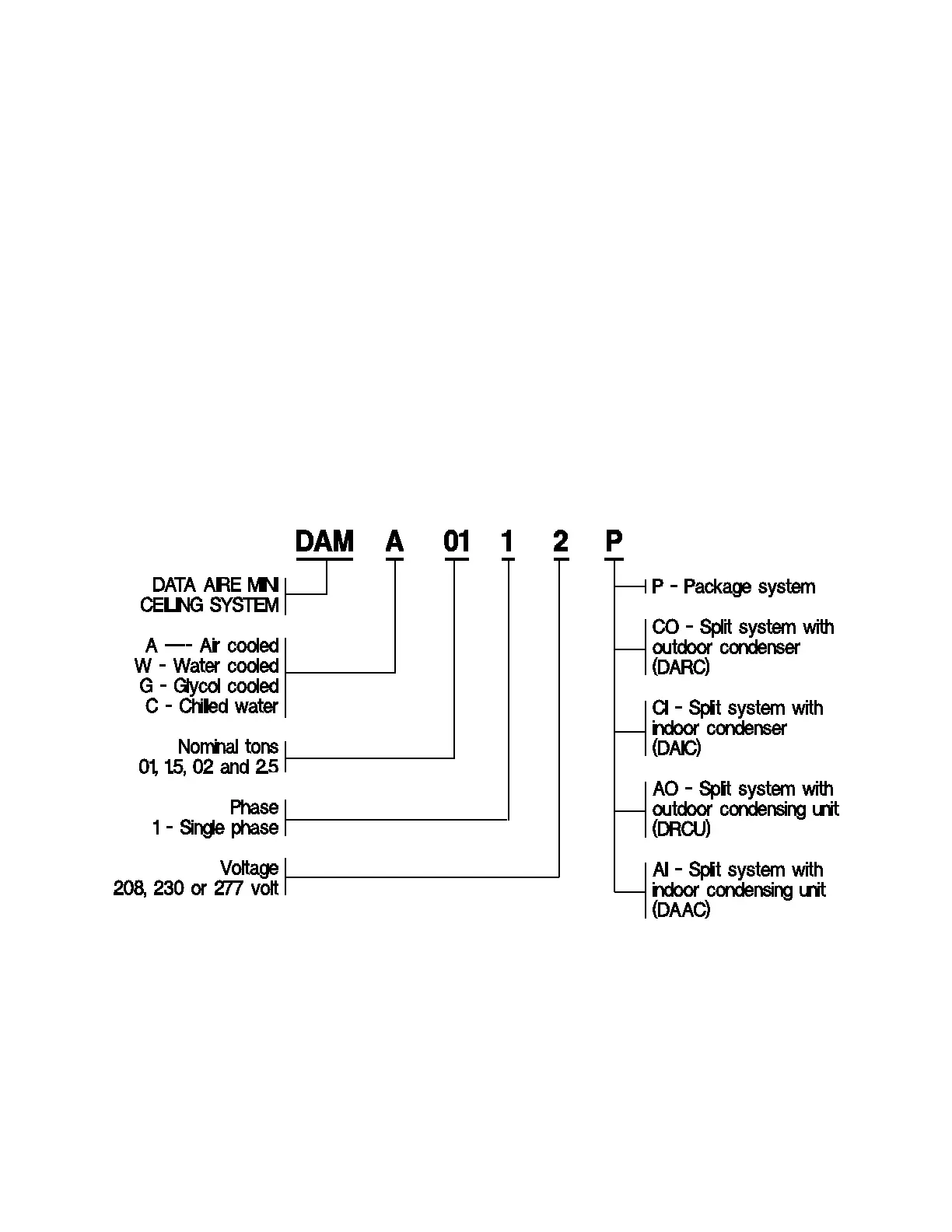

1.6 Model Identifi cation

Loading...

Loading...