2 2 4 R R

Operating instructions and warnings

20

Incasethegatestructuralfeaturesdonotallowyoutocomplywiththeaboveforcelimits,itispossible

touseexternalsafetydevicesinputs(terminalsno.11andno.12).“SIC1”and“SIC2”inputscanbe

configuredbysettingproperlyparameterno.18:

•P018=0“rib”modefunctioning:SIC1=motor1ribinput,SIC2=motor2ribinput.Whenoneofthe

twoinputsisactivatedthemovementdirectionofbothmotorsisinverted.Ifoneofthetwoinputsisacti-

vatedduringtheslow-downphase,theactivationisinterpretedasstrokeendthusstoppingthemovement

ofthemotorassociatedtothatinput.

•P018=1“photoelectricbarriers”modefunctioning:youcanuseeither“SIC1”or“SIC2”orbothof

them,butremembertoshort-circuittheunusedinput.Whenoneofthetwoinputsisactivated,themove-

mentofbothmotorsisstopped.

Ifyoupowerexternalsafetydevicesthrough+24VSICoutput(terminalno.14),theirproperworkingis

testedbeforeeachmanoeuvre.

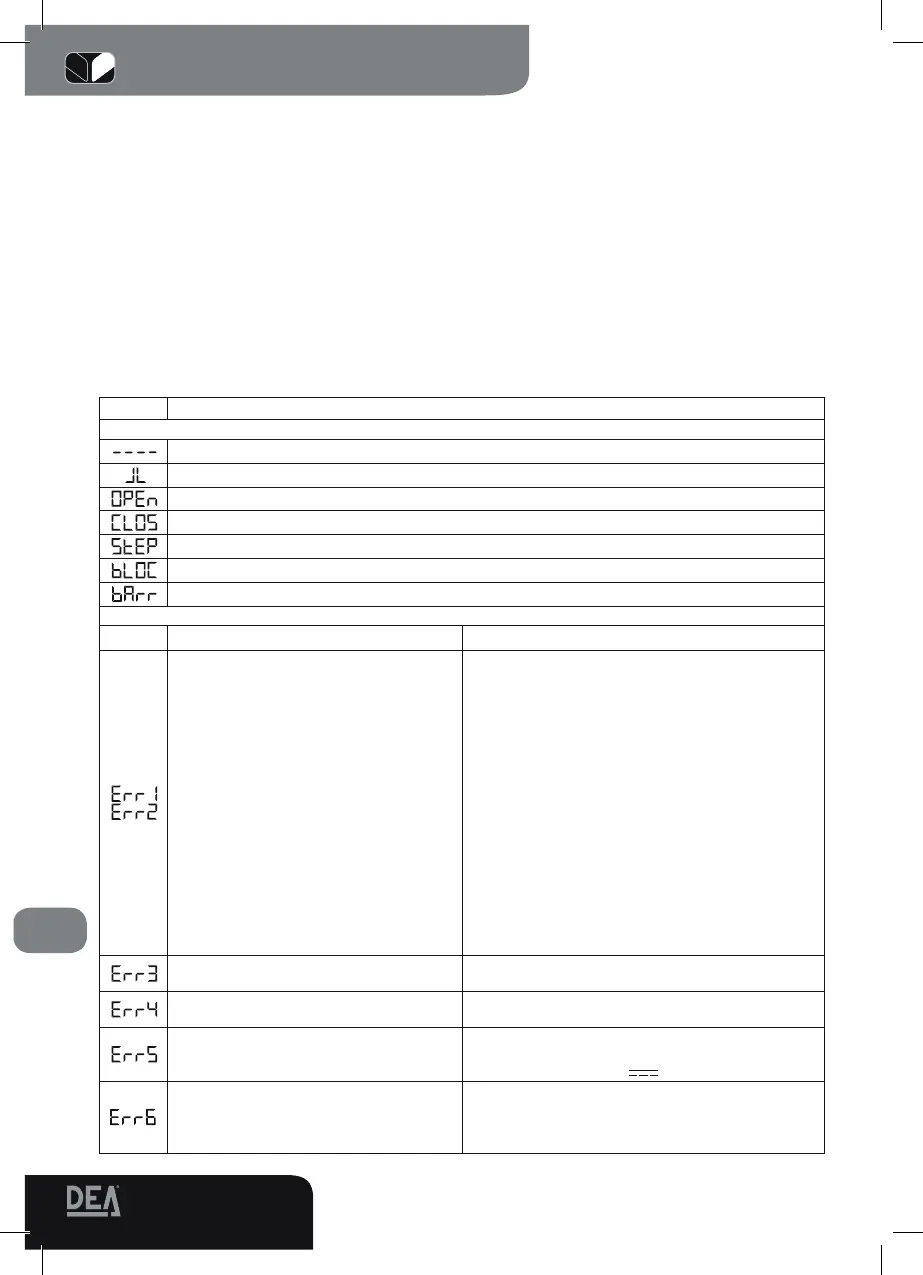

8.7 Messages shown on the display

224RRcontrolboardallowsyoutovisualizeonthedisplayseveralmessagesconcerningitsworking

statusandanymalfunction:

Message Description

MESSAGES CONCERNING WORKING STATUS

Gateisclosed

Gateisopen

Openingunderway

Closingunderway

Whileinstep-by-stepmode,thecontrolboardawaitsfurtherinstructionsafterastartcommand

Stopcommandreceived

Sic1orsic2activatedwhileworkinginbarriermode

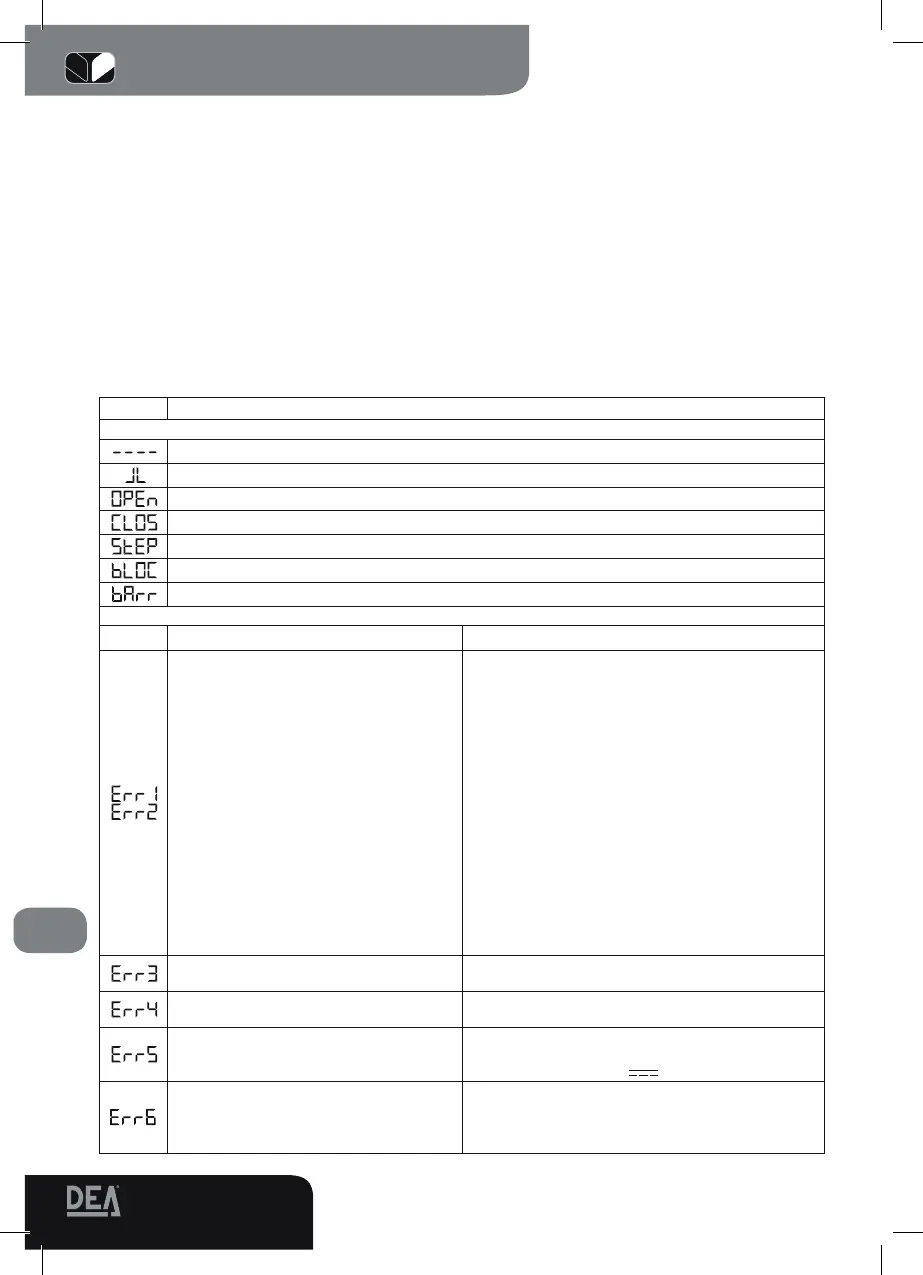

ERROR MESSAGES

Message Description Possible solutions

They point out that the gate has excee-

ded:

-(Err1), the max allowed number of

reversals (50) without ever reaching the

end of stroke (or stop) while closing;

-(Err2)themaxnumberofuninterrupted

operations (10) of the anti-crush safety

device;therefore an “emergency maneu-

ver”isunderway:thecontrolboardsets

the motors in a slow down phase and

searches the stops (or ends of stroke)

in order to reset the positioning system.

Oncethestops(orendsofstroke)while

closing are found again the message

disappearsandthecontrolboardawaits

further instructions “----” and then resu-

mesworkingnormally.

In case the gate is not properly closed after the

emergency maneuver (maybe because of false

stops or obstacles due to mechanical frictions),

proceedasfollows:

- Disconnect the power supply, check manually

that no particular frictions and/or obstacles are

presentduringthecompletestrokeofbothleafs.

Leavebothleafshalf-open.

-Connectthepowersupplyagainandsubsequen-

tlygiveastartpulse.Atthispointbothleafswill

starttocloseinslowdownphaseuntilreachingthe

stop(orendofstroke).Makesurethatthemaneu-

verisproperlycompleted.Adjustforceandmotor

speedvalues,ifneedbe.

Ifthegatekeepsworkinginappropriatelytryto

repeatthemotorstrokememorizationprocedure

(seeparagraph8.2)

Externalphotocellsand/orsafetydevices

areactivatedoroutoforder

Makesurethatallsafetydevicesand/orphotocells

installedareworkingproperly.

Themotorsarenotconnectedoritsi-

gnalscontrolboardfailure

Makesurethatthemotorsareproperlyconnected.

Ifthemessagereappearschangethecontrolboard.

Thecontrolboardpowersupplyvoltage

hasexceededtheallowedrange

Makesurethepowersupplyvoltageonthefaston

connect.no.29-30is22V~+/-10%andonfa-

stonno.27-28is27V+/-10%.

Possible motor overheating due to ob-

stacles hindering the doors movement.

The control board does not respond to

instructions

Remove any obstacle and wait until the message

“Err6” is replaced by message “bLOC” and the

control board responds to instructions again (a

fewseconds)

Loading...

Loading...