Dectron, Inc. March 2012

Owner’s Manual

DSH/DSV/RSH/DBH/RBH Series Dehumidifier

Blower Lubrication Maintenance Operation

Data subject to change without notice.

259

Risk of contact with moving parts. Can cause injury or death.

This product contains rotating parts and V-belt drives. Some procedures could

expose personnel to the risk of injury or death from contact with these parts.

Using only approved devices (e.g. locking safety switch), disconnect, lockout, and

tagout all sources of electrical energy before working inside the unit cabinet. Allow

adequate time for rotating parts to stop. Follow all applicable safety regulations.

WARNING

Initial Relubrication Schedule

Ball Bearing Pillow Blocks

Speed (RPM) 500 1000 1500 2000 2500 3000 3500 4000 4500

” through 1 ” 6 6 5 3 3 2 2 2 1

1 ” through 2 ” 6 5 4 2 2 1 1 1 1

2 ” through 2 ” 5 4 3 2 1 1 1

3 ” through 3 ” 4 3 2 1 1 1

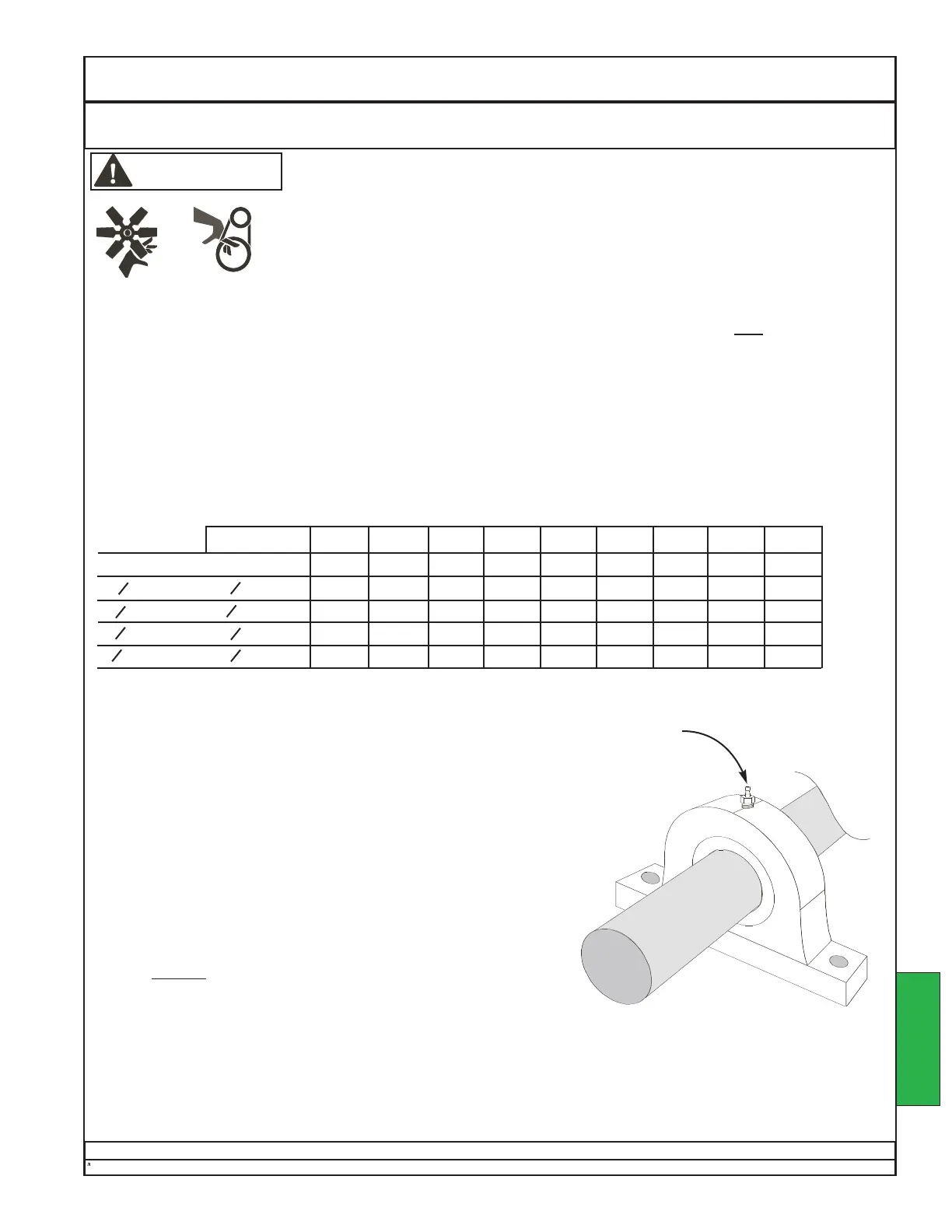

1. Be sure the electric power to the unit is OFF, locked out, and tagged out.

2. Clean all grease fittings or plugs to remove any paint, dirt, or dust.

3. If possible and safe to do so, slowly turn the blower by hand while adding grease.

4. Add grease just until a small amount of grease oozes from the seals.

5. Repeat for the bearing on the other end of the shaft.

6. When safe an practical to do so, return the blower to operation.

NOTE: Some units have more than one blower. See Product Description

for suggested search locations.

NOTE: The frequency of lubrication may have to be changed, based on

hours of operation, temperature, surrounding conditions, and the

condition of the purged grease.

NOTE: Grease the bearings before an extended shutdown or storage.

NOTE: During an extended shutdown, rotate the blower shaft

monthly

.

1

2

11

16

11

16

7

16

7

16

15

16

15

16

15

16

Shaft Diameter

Some smaller blowers may be permanently lubricated. Other blowers may have bearings that have grease

fittings or oil ports and require lubrication. Where this is the case, use the lubricating instructions provided on

the blower nameplate or in accompanying documents. If no instructions are available, then until the proper

instructions can be obtained

a) Use a high-quality NLGI No. 2 or No. 3 multipurpose ball-bearing grease with rust inhibitors and anti-

oxidant additives. Examples are:

Shell - Alvania No. 2

Gulf - Gulfcrown No. 2

Mobil - Mobilith AW2 / Mobilith SHC100

American - Rykon Premium 2

b) Follow the schedule below, based on size and speed of blower shaft.

OPERATION

Number of Months Between Lubrications

Loading...

Loading...