82

71.06952.02 - EN

INSTALLATION INSTRUCTIONS

19. GAS CONVERSION

The authorised Technical Assistance Service can convert this boiler to natural gas (G. 20) or liquid gas (G.31).

Carry out the following operations:

A) replace the nozzles of the main burner and the gas diaphragm (if tted);

B) new max. and min. calibration of the pressure regulator.

A) Replace the burner nozzles

rDBSFGVMMZQVMMUIFNBJOCVSOFSPGGJUTTFBU

rSFQMBDFUIFNBJOCVSOFSOP[[MFTNBLJOHTVSFUPGVMMZUJHIUFOUIFNUPQSFWFOUHBTMFBLT/P[[MFEJBNFUFSTBSFTQFDJàFE

in table 2.

B) Calibrate the pressure regulator

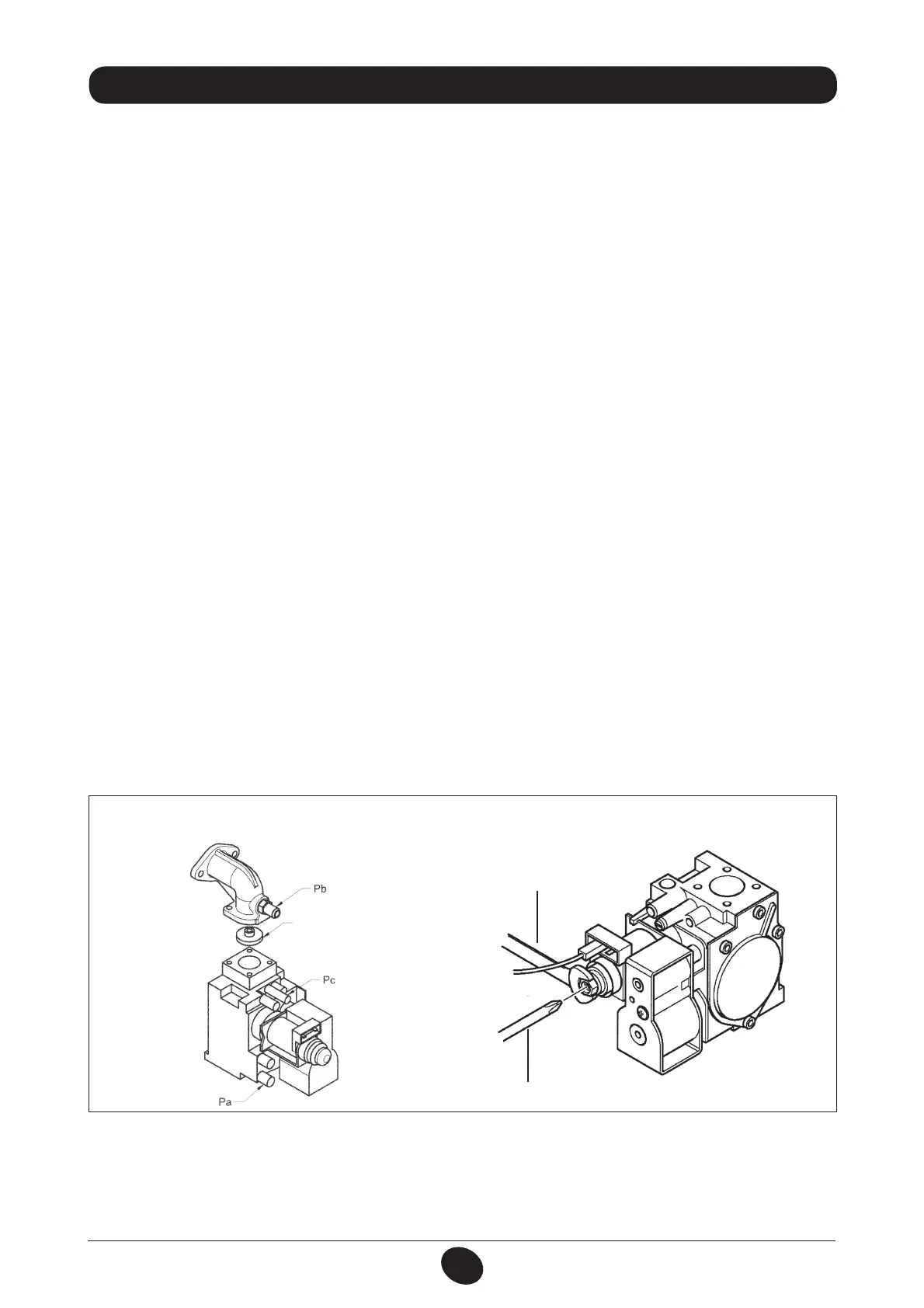

rDPOOFDUUIFQPTJUJWFQSFTTVSFUFTUQPJOUPGBEJGGFSFOUJBMQSFTTVSFHBVHFQPTTJCMZXBUFSPQFSBUFEUPUIFHBTWBMWF

pressure test point (Pb) (Figure 10). Only for models with sealed chambers, connect the negative pressure test point of

the manometer to a “T” tting in order to join the boiler adjustment outlet, the gas valve adjusting outlet (Pc) and the

pressure gauge. (The same measurement can be made by connecting the pressure gauge to the pressure test point

(Pb) after removing the front panel of the sealed chamber);

Measuring burner pressure using methods other than those described could lead to incorrect results as the low pressure

created by the fan in the sealed chamber would not be taken into account.

B1) Adjustment to nominal heat output:

rPQFOUIFHBTUBQBOETXJUDIUIFCPJMFSUPUIF8JOUFSNPEF

rPQFOBIPUXBUFSUBQUIBUDBOQSPWJEFBáPXSBUFPGBUMFBTUMJUSFTBNJOVUFPSNBLFTVSFUIFSFJTNBYJNVNIFBU

demand;

rSFNPWFUIFNPEVMBUPSDPWFS

rBEKVTUUIFUVCFCSBTTTDSFXBVOUJMUIFQSFTTVSFWBMVFTTIPXOJOUBCMFBSFPCUBJOFE

make sure that the dynamic inlet pressure of the boiler, measured at the gas valve pressure test point (Pa) (Figure 10) is

correct (37 mbar for propane or 20 mbar for natural gas).

B2) Adjustment to reduced heat output:

rEJTDPOOFDUUIFNPEVMBUPSQPXFSDBCMFBOEVOTDSFXUIFTDSFXCVOUJMBQSFTTVSFWBMVFDPSSFTQPOEJOHUPSFEVDFEIFBU

output is achieved (see tab. 1);

rSFDPOOFDUUIFDBCMF

rNPVOUUIFNPEVMBUPSDPWFSBOETFBM

B3) Final checks

rBUUBDIUIFBEEJUJPOBMQMBUFTVQQMJFEXJUIUIFUSBOTGPSNFSTQFDJGZJOHUIFUZQFPGHBTBOEUIFDBMJCSBUJPOQFSGPSNFE

Figure 10

gas valve

mod. SIGMA 845

b

a

0605_1502

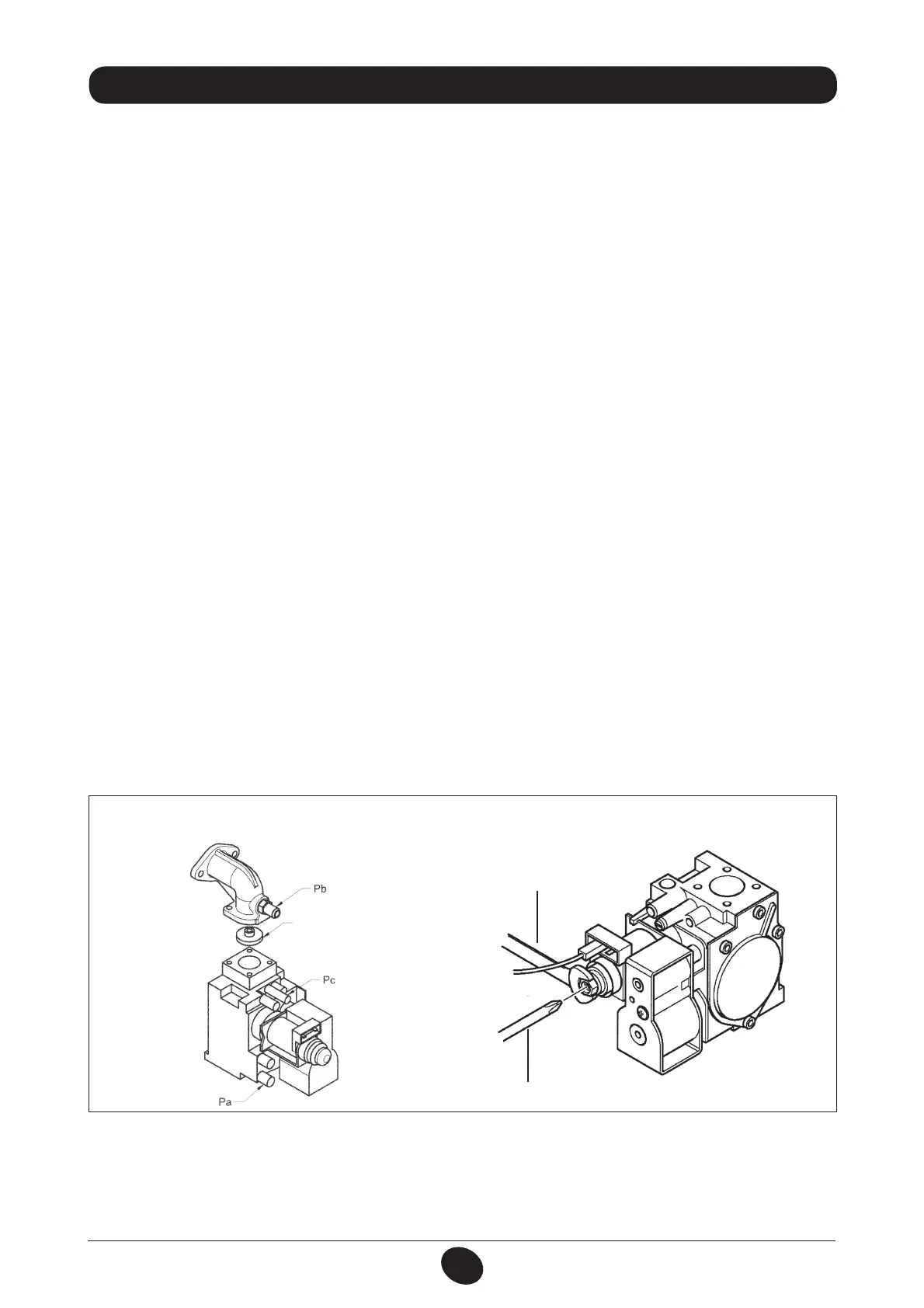

Figure 11

CG_2273 / 1008_2602

gas diaphragm

ATTENTION

If the natural gas inlet pressure is too low (less than 17 mbar) remove the gas diaphragm installed over the gas valve (g.

10) and set parameter ' on the electronic board (§21).

Loading...

Loading...