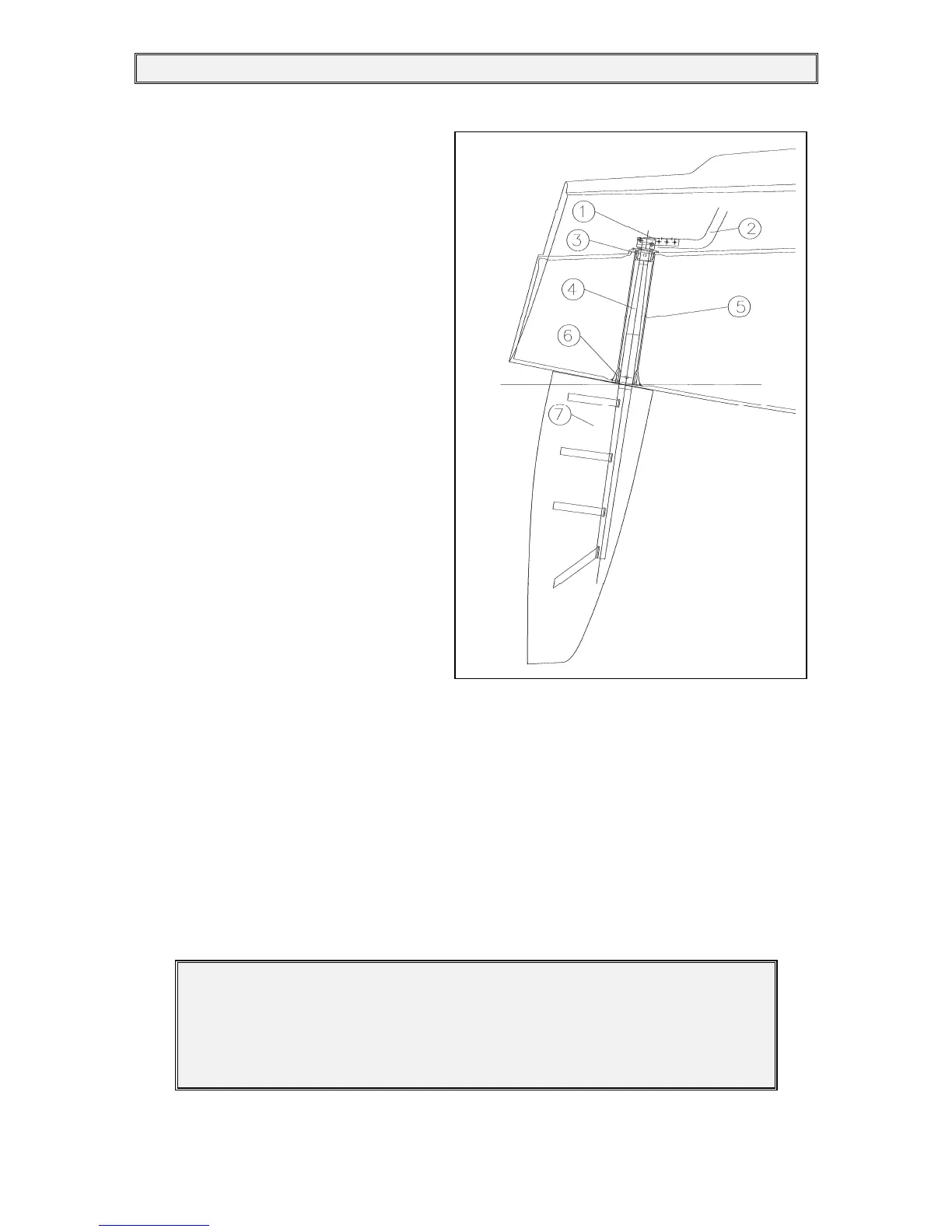

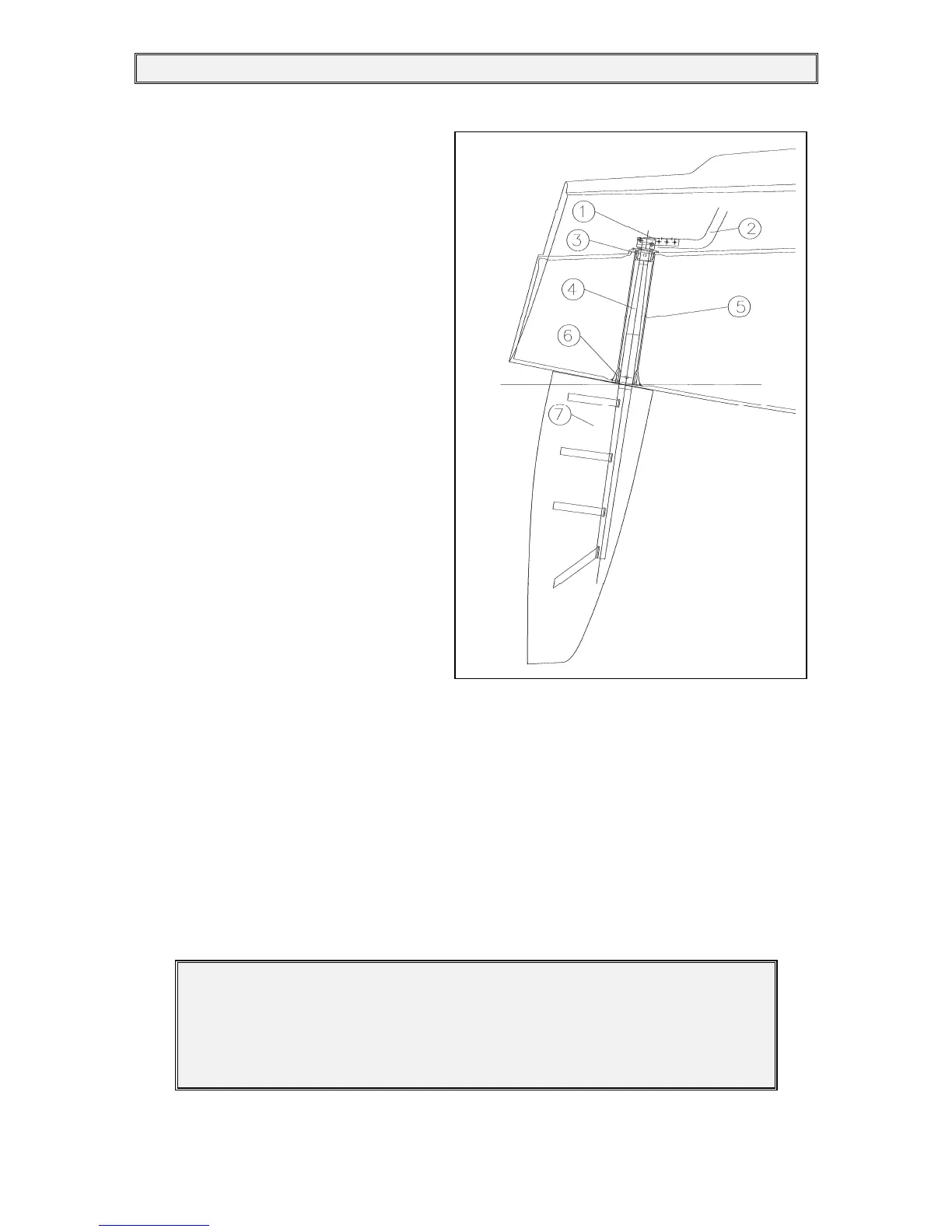

4.7 Rudder system

4.7.1 Tiller steering

Steering pedestal is integrated into deck.

1 Claming piece

2 Rudder tiller

3 Rudder bearing top

4 Rudder stock

5 Rudder tube

6 Rudderbearing lower

7 Rudder blade

4.7.2 Rudder blade and rudder bearing

The rudder blade is a modern prebalanced GF synthetic profiled blade with considerable

rudder force. The rudder shaft, diam. 69 mm, is made of aluminium. The rudder force from

the shaft to the rudder blade is transmitted with welded fittings. The rudder shaft sits in a

needle beaing Jefa 5T040 and below in a Jefa self aligning needle 5BT069.

The rudder is practically maintenance free. An annual cable tension check is however

necessary. Tension adjustment should be carried out if necessary. Every five years the rudder

should be dismantled, the bearing surfaces carefully cleaned, greased and then reinstalled.

Bear in mind that the rudder can only be “withdrawn” in a crane or above a pit after the

rudder quadrant has been loosened.

After re-installation the transmission cable must have its tension adjusted again.

IMPORTANT

Do not make sternway too quickly,

and always hold the wheel firmly.

Never let go of the wheel!

The stop mechanism and the cables are unnecessarily put under strain

Loading...

Loading...