4.7.3 Rudder blade and rudder bearing

The rudder blade is a modern prebalanced GF synthetic profiled blade with considerable

rudder force. The rudder shaft, diam. 44 mm, is made of stainless steel, offset and is narrower

at the lower end. The rudder force from the wave to the rudder blade is transmitted with

welded fittings. The rudder shaft is held above in a JP3 pendulum bearing, type 1 Ref

10.13.03 and below in a JP3 bearing, type 1 Ref 10.14.04.

The rudder is practically maintenance free. An annual cable tension check is however

necessary. Tension adjustment should be carried out if necessary. Every five years the rudder

should be dismantled, the bearing surfaces carefully cleaned, greased and then reinstalled.

Bear in mind that the rudder can only be “withdrawn” in a crane or above a pit after the

rudder quadrant has been loosened.

After re-installation the transmission cable must have its tension adjusted again.

IMPORTANT

Do not make sternway too quickly,

and always hold the wheel firmly.

Never let go of the wheel!

The stop mechanism and the cables are unnecessarily put under strain

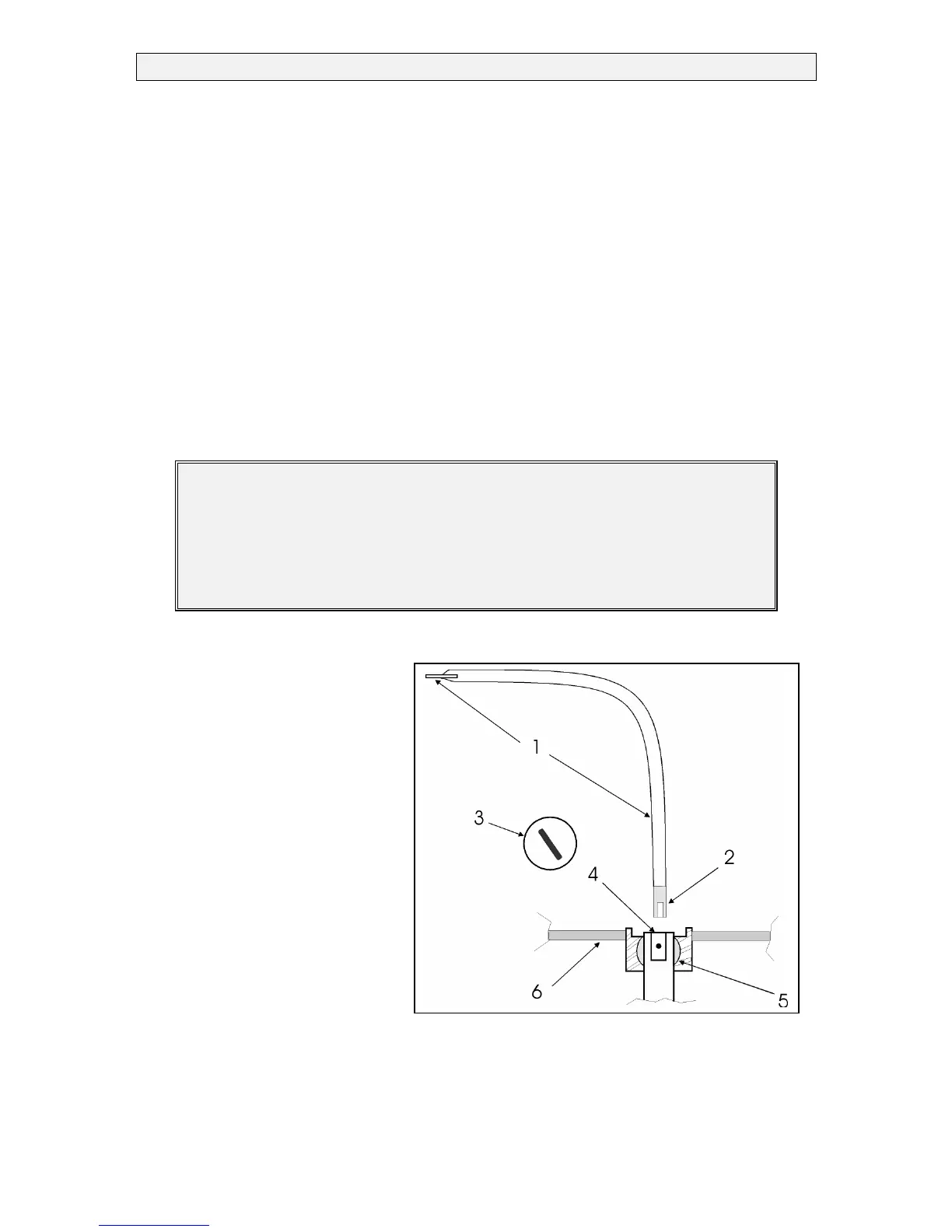

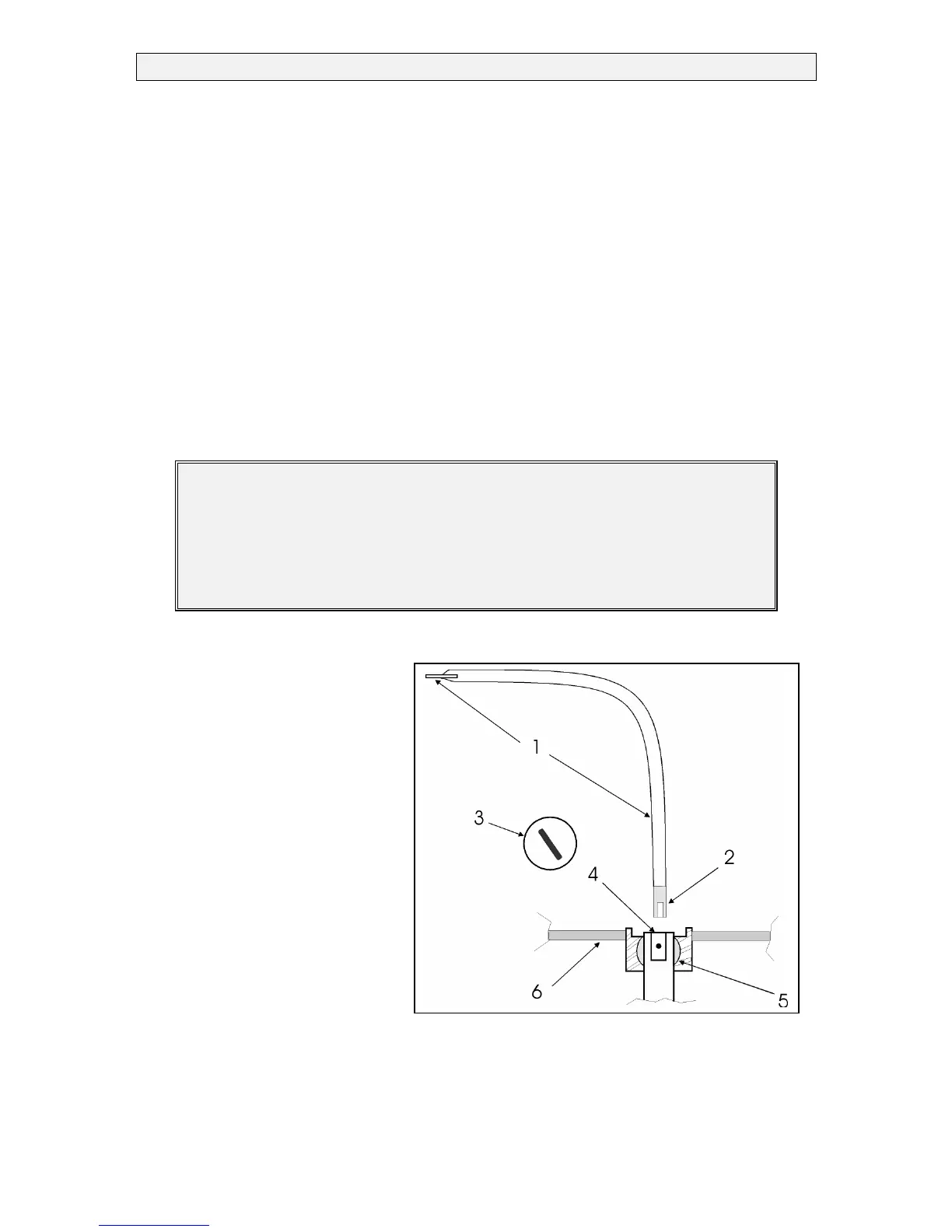

4.7.4 Emergency tiller

The emergency tiller is stowed in

the galley locker port side. One end

of the emergency tiller is in fact a

screw, with which the cover of the

upper bearing can be loosened. The

other end is equipped with a nut

that must be placed on the

connecting plate in the upper end of

the rudder shaft. As skipper, you

should get used to the hand grip and

have tried out the tiller.

Components

1. Emergency tiller

2. Nut for insertion

3. Cover of upper bearing

4. Blind hole with connecting plate

5.

Pendulum bearing

6. Cockpit floor

Figure 20: Emergency head

Loading...

Loading...