SM6000 DELTA ELEKTRONIKA BV

July 2003, rev. May 2008 OPERATING MAINTENANCE TROUBLE SHOOTING CALIBRATING Page 4 - 4

If DIP switch 4 of SW1 is op erated when the unit is

turned on, the out put will shutdown to avoid accidental

dam age.

• The max. num ber of slaves is only limited by the max.

total voltage of 600 V.

12)

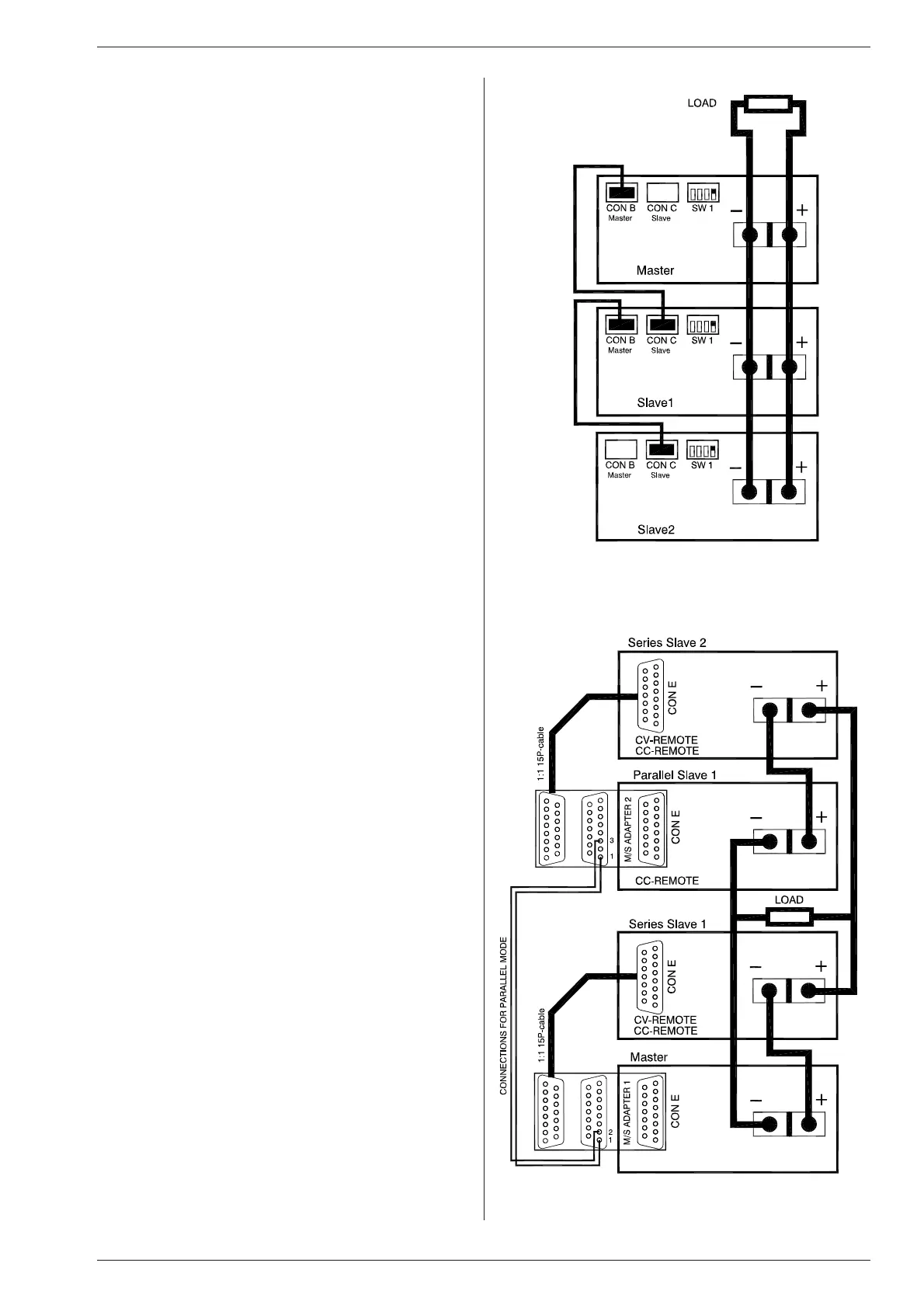

MASTER / SLAVE PAR AL LEL OP ER A TION

• Note: Mas ter / Slave par allel is not rec ommended

for more than 3 units, con sult factory for using

more than 3 power sup plies in parallel.

• First con nect output terminals and test sys tem in

nor mal par al lel op eration. Ensure that all power

con nec tions are re li able.

• Second, switch off all units. To con nect the slaves with

the mas ter via CON B and CON C, use standard RJ45

con nec tors ac cord ing to fig. 4 - 11.

On all units put DIP switch 4 of SW1 in po sition ON to

set the units in M/S par allel mode. In this mode the

DCF LED, DCF re lay and DCF sta tus on the slaves are

disabled be cause the slaves are al ways in CC mode.

• After turning the units on again, the slaves will be in

Remote CC mode and the Key lock (see pre vious para -

graph 2) is ac tivated. This is be cause the unit au tomat-

ically de tects the presence of the RJ45 con nec tor in

CON C (if this ca ble is con nected to an other unit).

If the RJ45 con nector is removed from CON C when

the unit is turned on, the out put will shutdown to avoid

ac ci den tal dam age.

If the ca ble is in serted when the unit is turned on, the

output shuts down, the unit changes to Re mote CV /

CC, the Keylock will be activated and the out put will

turn back on.

If DIP switch 4 of SW1 is op erated when the unit is

turned on, the out put will shutdown to avoid accidental

dam age.

• Stack the units to cre ate a min imum dis tance be tween

the units. Keep the load close to the mas ter.

Use cop per strips (pre ferred) or short thick cables to

connect the units. Make sure the strips are mounted

with a min imum length to keep the volt age drop be -

tween a unit and the bus bar be low 10 mV. Also keep

the strips close to each other to have a low in ductance.

Not fol low ing these in struc tions can cause in sta bil ity.

• The S- and S+ could be connected to the load if

desired, but this is not rec ommended be cause of the

com plex ity and pos si ble instability.

13)

PAR AL LEL OP ER A TION OF FAST

PRO GRAMMING VER SIONS:

• Master / Slave op eration is not rec ommended.

• Nor mal par al lel op er a tion can give prob lems, each

combination has to be tested first in com bination with

the load.

14)

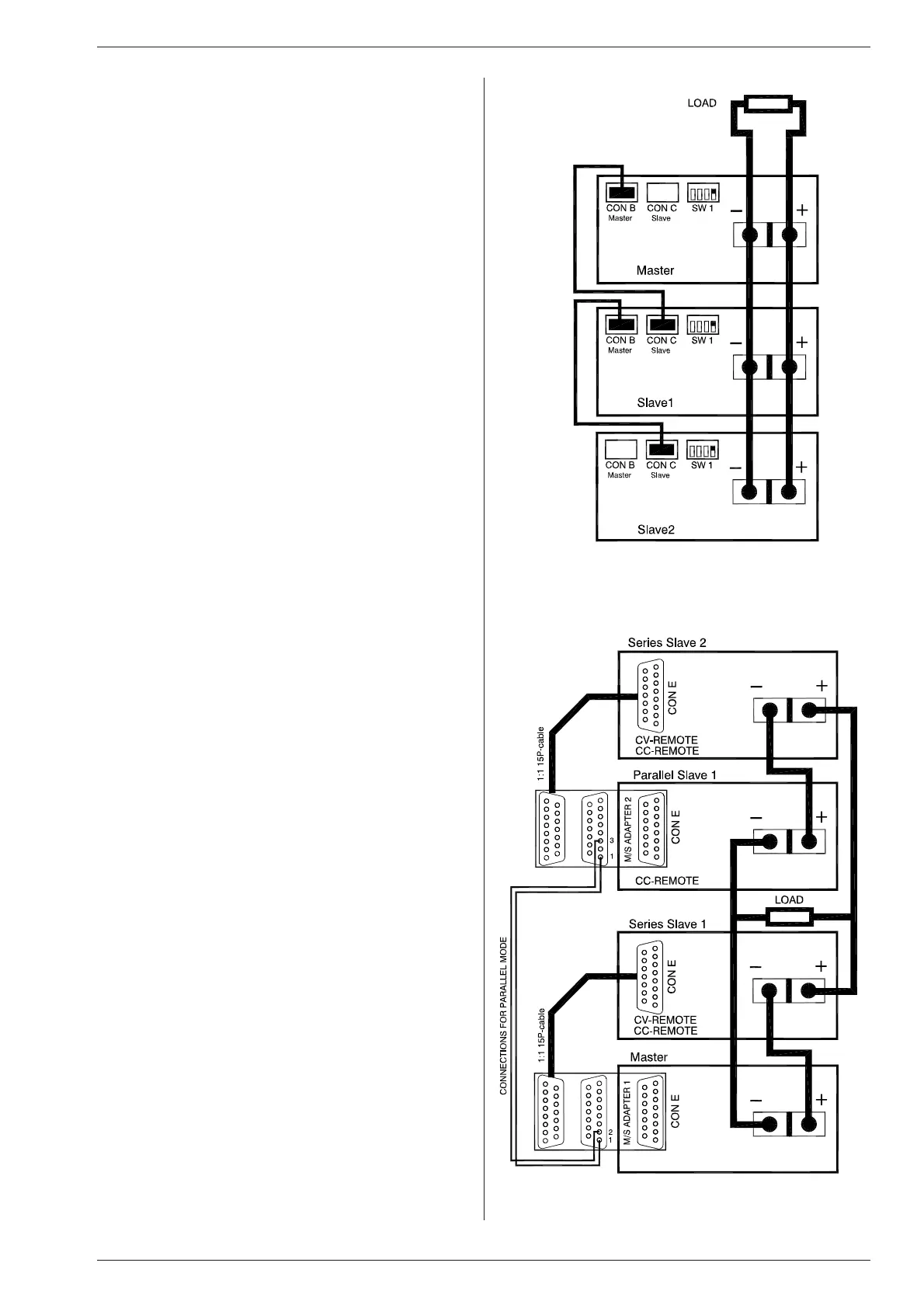

MASTER / SLAVE MIXED SERIES /

PAR AL LEL OP ER A TION

• For complex com binations as mixed se ries - parallel,

always use a MASTER / SLAVE SE RIES ADAPTER.

• See fig. 4 - 12 for an ex ample of how to connect 2 units

in se ries in par allel with 2 units in se ries, controlled by 1

mas ter.

• Set the pro gramming mode with the knob Re mote / Lo -

cal on the front panel. The se rial slaves must be in Re-

mote CV- and CC-mode. The par allel slave must be in

Remote CC-mode and the CV-potmeter must be fully

opened.

• Note: A Mas ter / Slave combination can al ways be

programmed, also with the IEEE488/RS232 con trol ler

(PSC-488 / PSC-232

(both δ-prod ucts)).

fig. 4 - 11

Master / Slave parallel connections

fig. 4 - 12

Master / Slave mixed series - parallel connections

Loading...

Loading...