3. Instruction Set

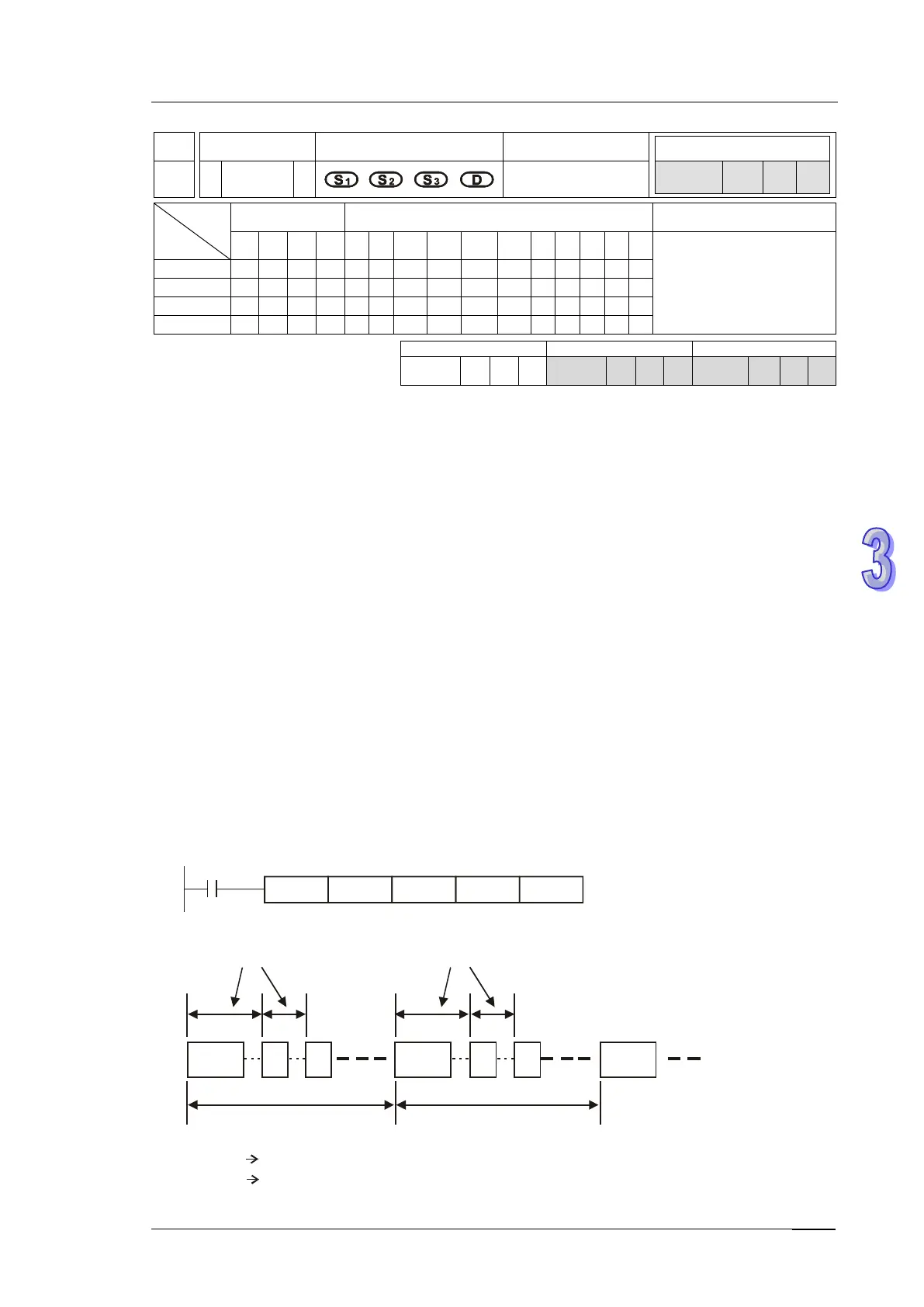

API

Mnemonic Operands Function

88 D

PID

PID control

Type

OP

Bit Devices Word devices Program Steps

X Y M S K H KnX

KnY

KnM

KnS

T C D E F

PID : 9 steps

DPID: 17 steps

SS2

SX2

SS2

SX2

SS2

SX2

Operands:

S

1

: Set value (SV) S

2

: Present value (PV) S

3

: Parameter setting (for 16-bit instruction, uses

20 consecutive devices, for 32-bit instruction, uses 21 consecutive devices) D: Output value

(MV)

Explanations:

1. This instruction is specifically for PID control. PID operation will be executed only when the

sampling time is reached. PID refers to “proportion, integration and derivative”. PID control is

widely applied to many mechanical, pneumatic and electronic equipment.

2. After all the parameters are set up, PID instruction can be executed and the results will be

stored in D. D has to be unlatched data register. (If users want to designate a latched data

register area, please clear the latched registers to 0 in the beginning of user program.

Program Example:

1. Complete the parameter setting before executing PID instruction.

2. When X0 = ON, the instruction will be executed and the result will be stored in D150. When

X0 = OFF, the instruction will not be executed and the previous data in D150 will stay intact.

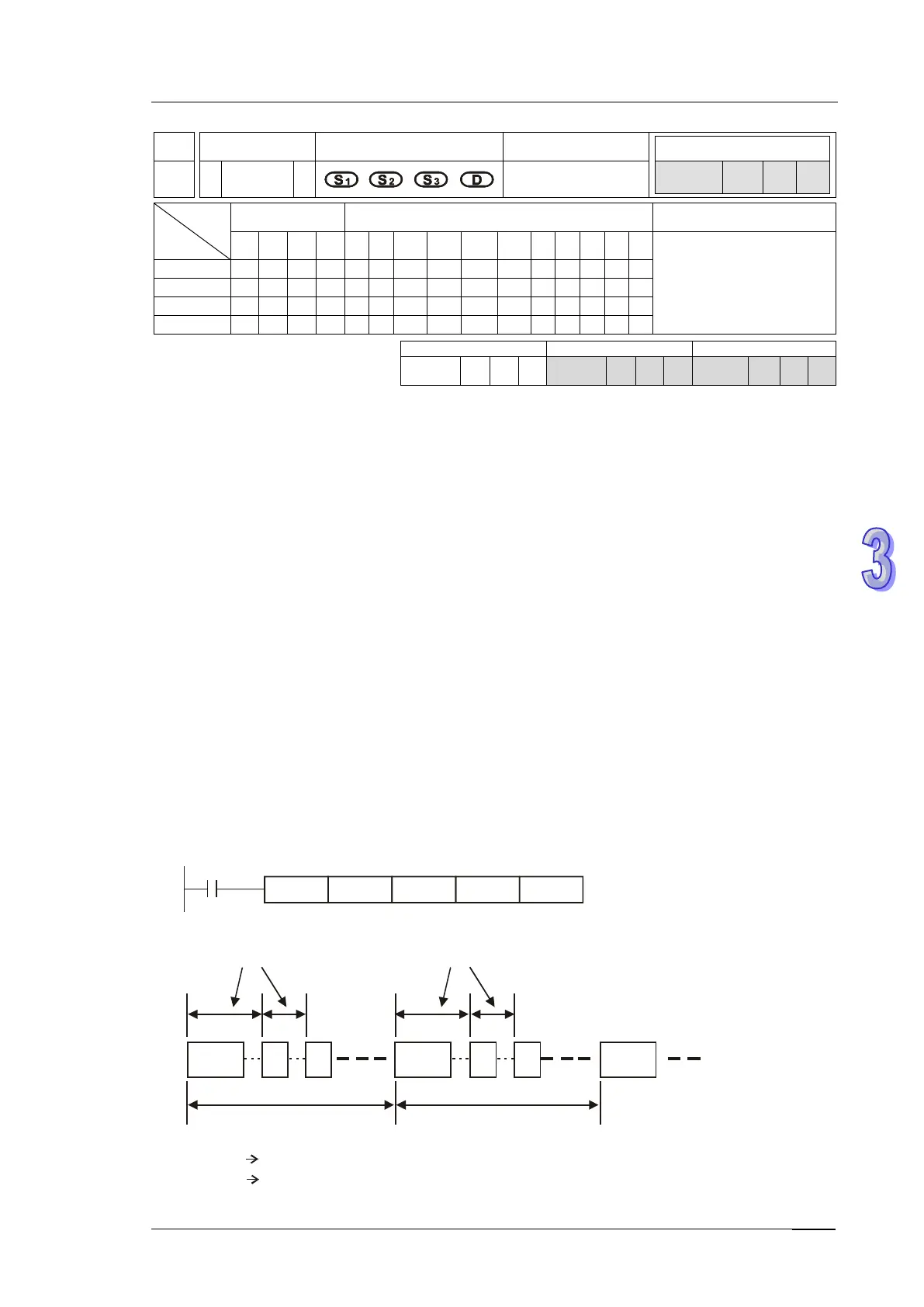

3. Timing chart of the PID operation (max. operation time is approx. 80us)

A + B

B B B B

A+B A+B

#1

#2

Scan cycle Scan cycle

Sampling time (Ts) Sampling time (Ts)

Note: #1 The time for equation calculation during PID operation (approx. 72us)

#2 The PID operation time without equation calculation (approx. 8us)

Loading...

Loading...