3. Instruction Set

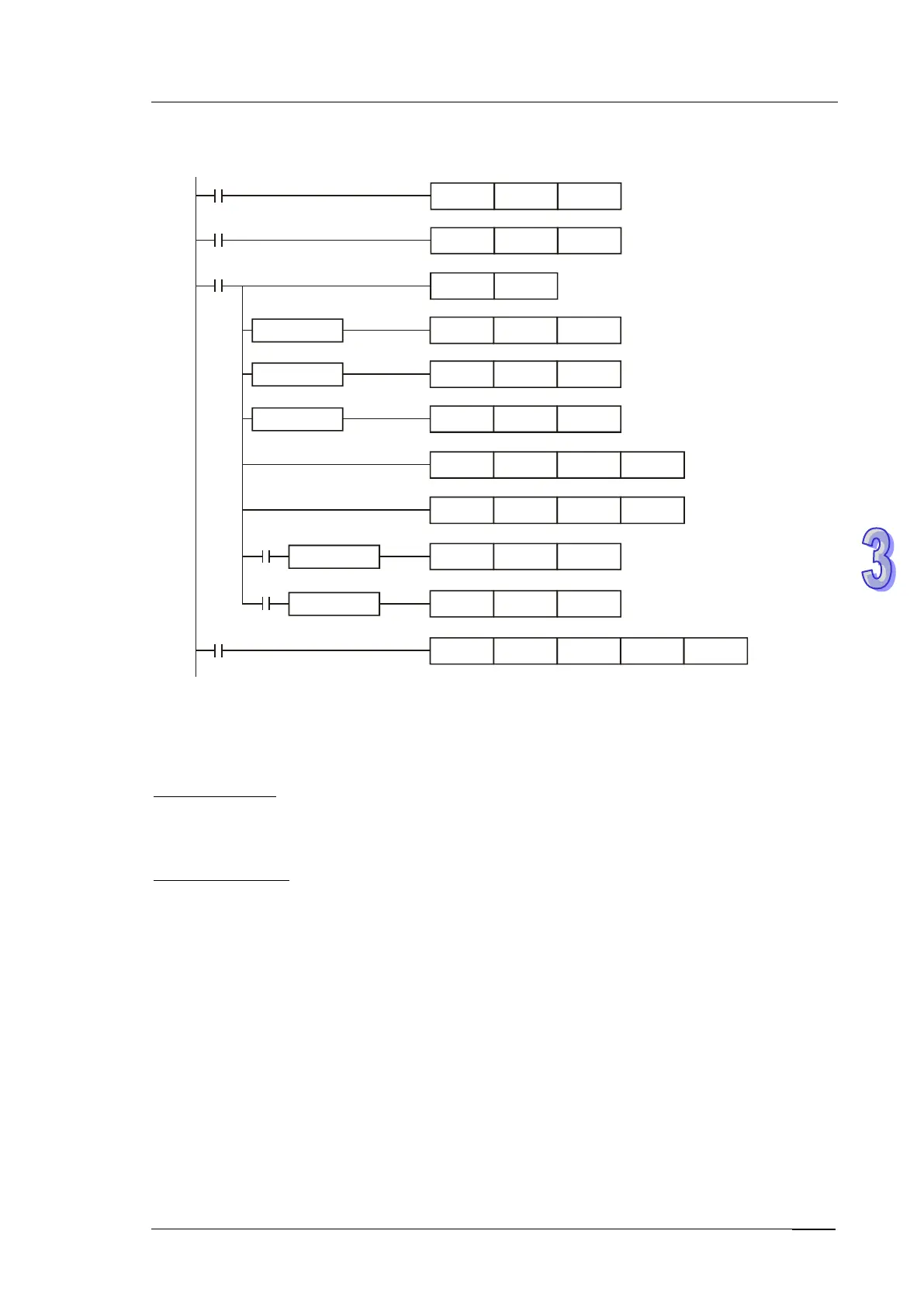

Example program of SV ramp up function:

M1002

MOV K10 D3

M10

M0

TMR T0 D3

T0

RST

T0

MOV K50 D2

D1D0>

MOV

K-50

D2

D1D0<

MOV K0 D2

D1D0=

ADD D2 D1 D1

CMP D2 K0

M10

D0D1

<

MOV D0 D1

M12

D0D1

>

MOV D0

D1

M0

PID D1 D1116 D10 D5

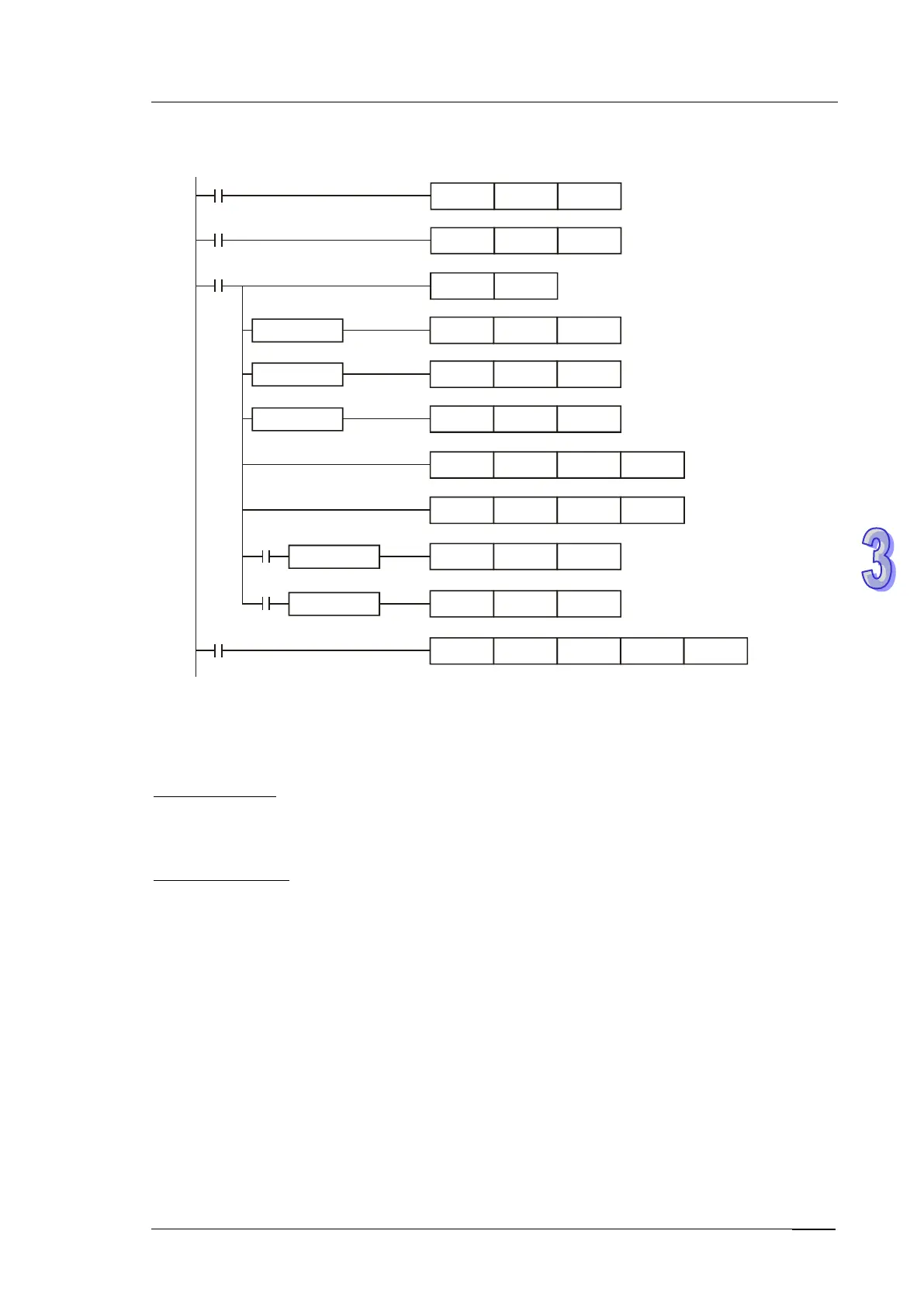

Application 2:

Speed control system and pressure control system work individually (use diagram of Example 2)

C

ontrol purpose:

After the speed control operates in open loop for a period of time, adding pressure control system

(PID instruction) to perform a close loop control.

Control properties:

Since the speed and pressure control systems are not interrelated, we have to structure an open

loop for speed control first following by a close loop pressure control. If users afraid that the

pressure control system changes excessively, consider adding the SC ramp-up function illustrated

in Application 1 into this control. See the control diagram below.

Loading...

Loading...