3

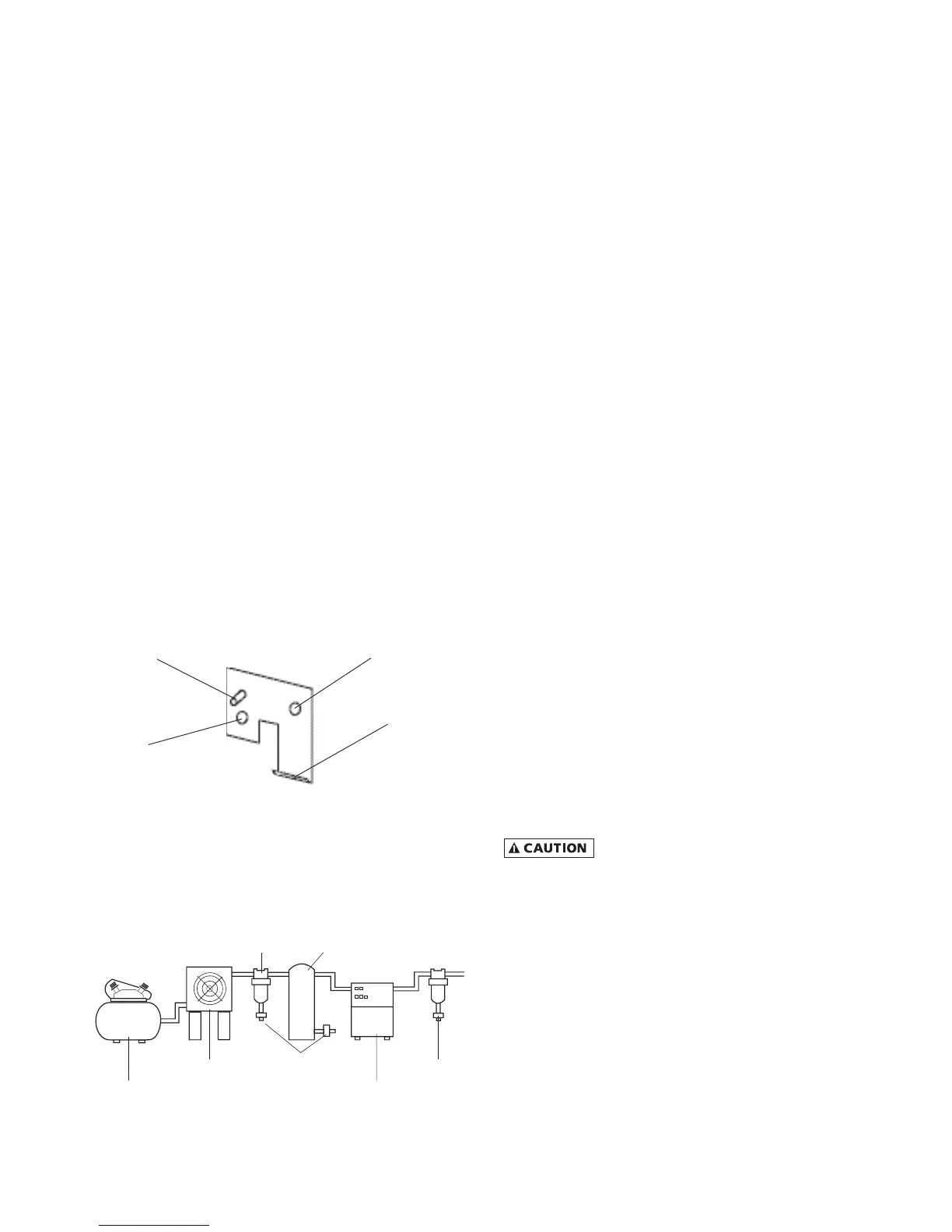

Compressor

Oil Removal

Filter

Aftercooler

Automatic Drain

Dryer

Separator

Receiver

TYPICAL COMPRESSED AIR SYSTEM

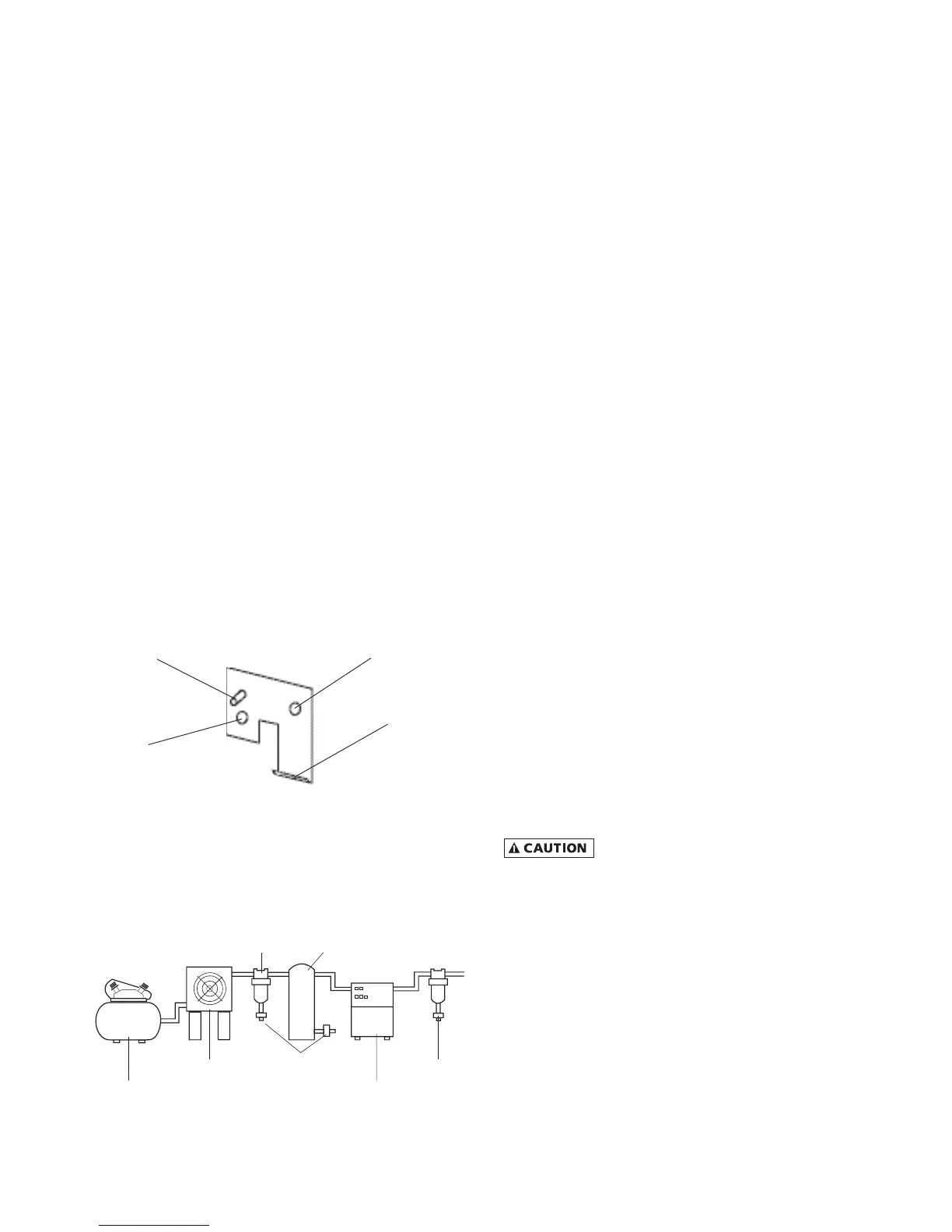

Locking Clip Stud

Existing Installation

New Installation

Dryer Hanger

OPTIONAL WALL MOUNTING BRACKET

(Retrofits models 8005 - 8015)

INSTALLATION

Ambient Air Temperature

Locate the dryer indoors where the ambient air

temperature will be between 40°F and 100°F. Intermittent

operation at ambient temperatures up to 113°F will not

damage the dryer but may result in a higher dew point

ordryershutdownduetohighrefrigerantdischarge

pressure (see Field Service Guide).

Do not operate air-cooled dryers at ambient air

temperatures below 40°F. Such operation may result in

lowsuctionpressure,causingfreeze-up.

Callyourlocaldistributorifprolongedoperationat

ambient temperatures above 100°F or below 40°F is

unavoidable.

Location and Clearance

Mount the dryer on a level base. Install the dryer in

aclean,well-ventilatedareatoreducefoulingofthe

condenser coils with dirt and dust.

Wall Mounting - Dryer may be wall mounted by using

anoptionalwallmountingbracket.clearancemustbe

maintained on all other sides as indicated.

Vapors and contaminants corrosive to copper and

aluminummustnotbeintheareaofthedryerorair

compressorintake.Allowatleast6inchesclearancefrom

thefrontandfromthecondensercoilserviceaccess.

Installthedryerwiththeframelevel.Anchorboltsarenot

required.

System Arrangement

Liquidwaterintheinletairwilladverselyaffectthe

performanceofthedryer.Installthedryerdownstreamof

anaftercoolerorseparatorsothatthetemperatureofthe

dryerinletairdoesnotexceed122°Fandtheinletairdoes

not contain any liquid water.

Mostcompressedairsystemsrequireltersforremoval

ofsolidandliquidcontaminants.Whenanoil-removal

lterisused,itshouldbeinstalleddownstreamofthe

refrigerateddryer.Thedryerwillremovesomeentrained

dirt,extendingthelifeofthereplaceablelterelement.

Outlet air temperature may be 10 to 30 degrees higher

than inlet air temperature. This is normal. Consult your

distributorifaloweroutletairtemperatureisrequired.

Piping and Connections

Pipingmustbefurnishedbytheuserunlessotherwise

specied.Connectionsandttingsmustberatedforthe

maximumoperatingpressuregivenonthedryerdata

plate and must be in accordance with applicable codes.

Supportallpiping;donotallowtheweightofanypiping

tostressthedryerorlters.Inletandoutletshutoffvalves

and a bypass valve are recommended. Piping should be

atleastthesizeoftheinletandoutletconnectionsto

minimizepressuredropintheairsystem.SeeEngineering

Datasectionfordryerinletandoutletconnections.

Removing Condensate

A separator with an automatic drain valve is supplied with

each dryer. The user must install a separate discharge line

atthedrainconnectiontocarryoffcondensatetoan

environmentally approved condensate collection/disposal

system. Securely anchor drain line to prevent whipping.

Ifcloggingoftheautomaticdrainisaproblem,installa

particulatelterbeforethedryertokeepsolidparticles

fromenteringthedryer.Contactyourlocaldistributorfor

theappropriateparticulatelter.

Electrical Connections (See Figure 1)

Dryer is designed to operate on the voltage, phase and

frequencylistedontheserialnumbertag.Referencetag

priortomakingelectricalconnection.Dryersaresupplied

withacordandplug.Installinreceptacleofproper

voltage.

Operationofdryerswithimproperline

voltageconstitutesabuseandcouldaffectthedryer

warranty.

Loading...

Loading...