I-951 Page 6 of 8

Rev. F-43693 2/14/2018

Troubleshooting

(Some models may not include all items listed below)

Symptom Probable Cause Remedy

Proportioner fails to draw

chemical properly.

1. Insufficient water supply pressure.

2. Foot valve has dirt/chemical build-up.

3. Proportioner metering tip clogged with

dried chemical.

4. Mineral deposits are located on Air

Gap nozzle.

5. Bucket fill (4 GPM) side appears to

have slow flowing water stream.

1. 20 PSI is the minimum allowable pressure. Seek

Plumber if necessary to increase water pressure.

2. Soak in hot water to clean.

3. Soak in hot water to clean interior passages.

4. Soak nozzle and inlet screen in hot water or

product such as CLR to clean mineral deposits.

5. Flow disc assembly must be removed from lower

section of water valve assembly if installed.

“Air Gap” Proportioner is

dripping or spraying a mist

(fan pattern) of water.

1. Mineral deposits are located on Air

Gap nozzle.

1. Soak nozzle and inlet screen in hot water or off

the shelf product such as CLR to clean and remove

mineral deposits.

Water valve is not shutting

off completely.

1. “Sliding lever” return spring may be

missing.

2. “Sliding lever” is not returning all the

way down due to interference between

the sliding lever and either the

chemical supply and/or outlet tubing.

3. Bucket fill outlet hose is catching the

bottom edge of the sliding lever during

normal usage.

1. Remove cover and visually check for sliding lever

return spring. Replace if missing.

2. Remove cover and visually check for any tubes

rubbing the sliding lever. Routing of chemical

supply and outlet tubing must not restrict the

movement of the sliding lever. Reroute tubing.

3. Don’t pull the bucket fill outlet hose too tight from

either side otherwise sliding lever may not return

properly.

Water valve is leaking. 1. Enclosing tube nut is too loose.

2. One or more of the valve o-ring

connections are out-of-position.

Identify each leak before disassembly.

1. Shut water supply off first. Hand-tighten the

enclosing Hose nut. Do not overtighten w/tool.

2. “O-ring” seals may be pushed out of place or

missing when sub-assembling valve together.

Threaded connections are

leaking water.

1. The connection between the blend

center and water supply line is too

loose or rubber washer is missing.

2. Backflow prevention devices and/or

proportioners are too loose.

1. Shut water supply off first. Carefully tighten the

female hose coupling on the blend center to the

inlet water supply line. Do not overtighten.

2. Tighten loose connection(s) with tools if

necessary. Do not overtighten if using tools.

Proportioner continues to

draw chemical after water

valve is closed.

1. Concentrated chemical is positioned

higher than the proportioner.

1. Move the concentrated chemical so it is lower than

the proportioner.

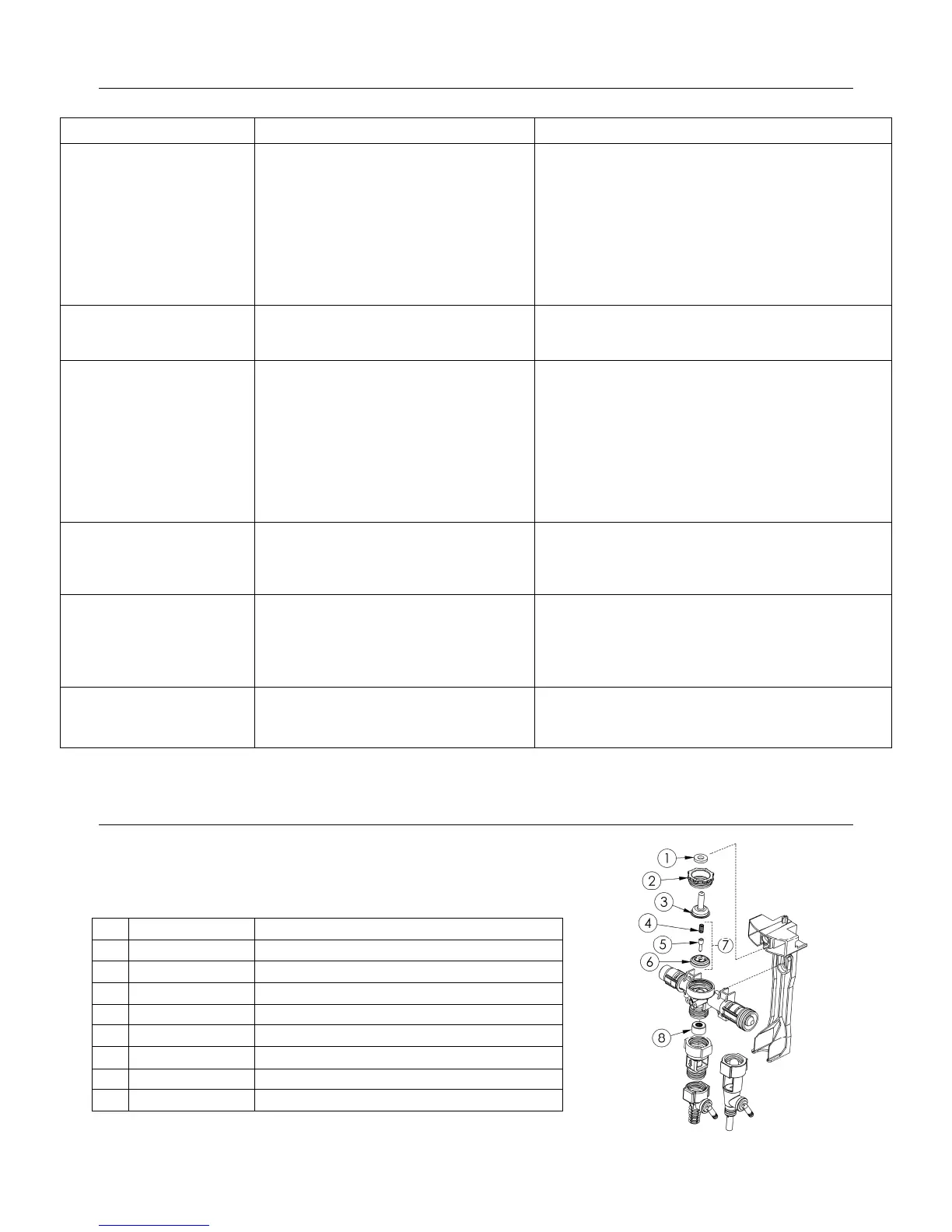

Parts List (See pages 6-8)

BOTTLE/HOSE FILL APPLICATIONS

NO. PART NO. DESCRIPTION

1 63-35 Magnet

2 98-7-2 Enclosing Tube Nut

3 41-7-25 Enclosing Tube

4 98-41-1 Spring

5 98-24-1 Plunger

6 41-15-10 Diaphragm With Center Hole EPDM

7 98-25-1 Bottle/Hose Repair Kit

8 89-20-1 Flow Disc Assembly (1 GPM only)

Loading...

Loading...