C-110-170-200E R11 Page 12

General Preventive Maintenance Guide

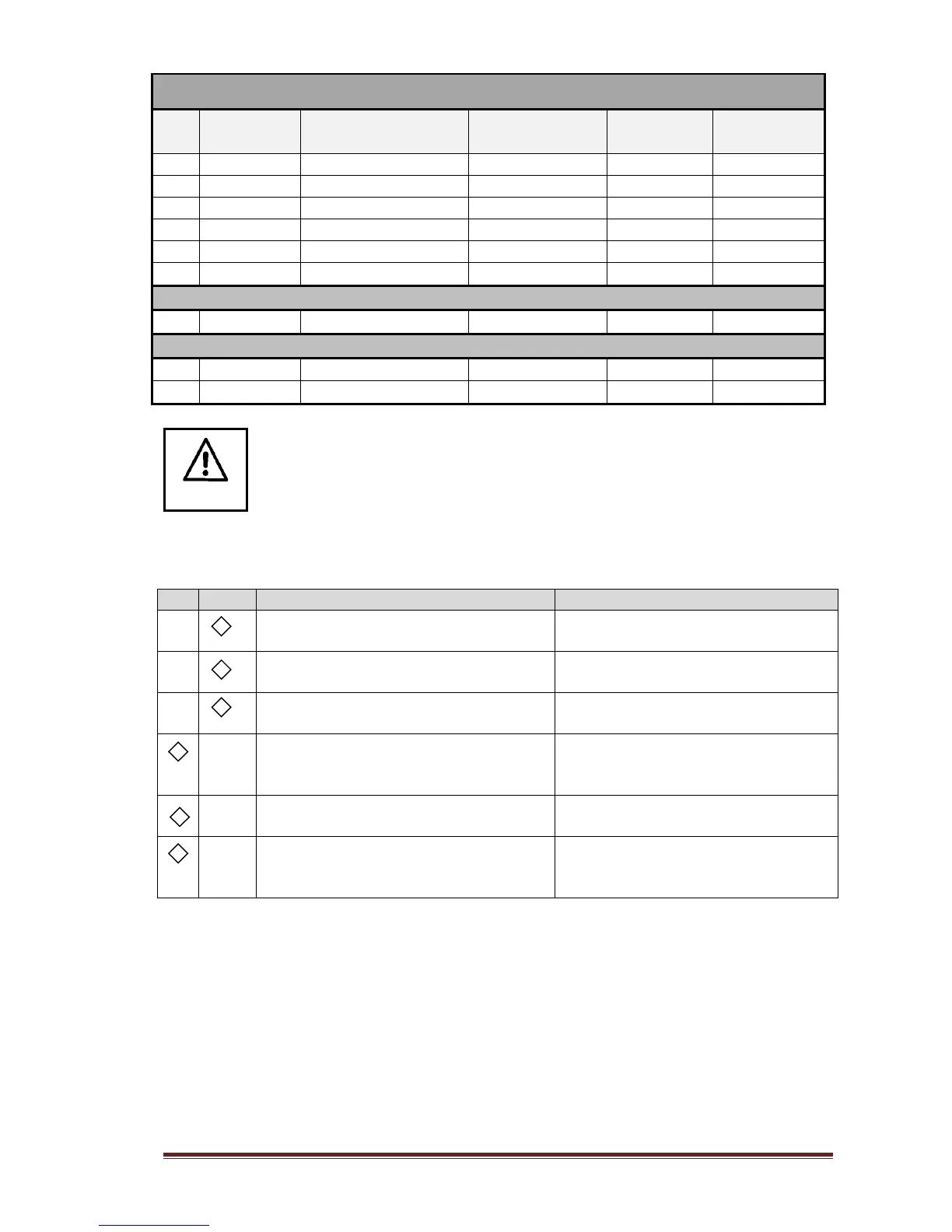

No Part No. Description Machine Model

Quantity

required

Service

Hours

1 700560004 Valve Kit All

1

600-800

2 700560011 Oil seal kit All

1

600-800

3 700560005 Piston kit 15mm C-110E/C-150E

1

600-800

4 700560008 Piston kit 18mm C-170E/C-200E

1

600-800

5 700560137 Water seal kit C-110E/C-150E 1 600-800

6 700560139 Water seal kit C-170E/C-200E 1 600-800

Unloader Valve

7 700540991 Repair kit All 1 400

Trigger Lance

8 700551517 Seat gasket repair kit All 1 400

9 700551520 Swivel repair kit All 1 400

Above guide is based on machine operating with fresh water of ambient temperature

not more than 30 degree Celsius. Preventive maintenance is necessary to maintain

pump`s performance, and Warranty on consumables parts only applies in the events

of manufacturer`s defects. Please read section 6 under WARRANTY clause for more

information.

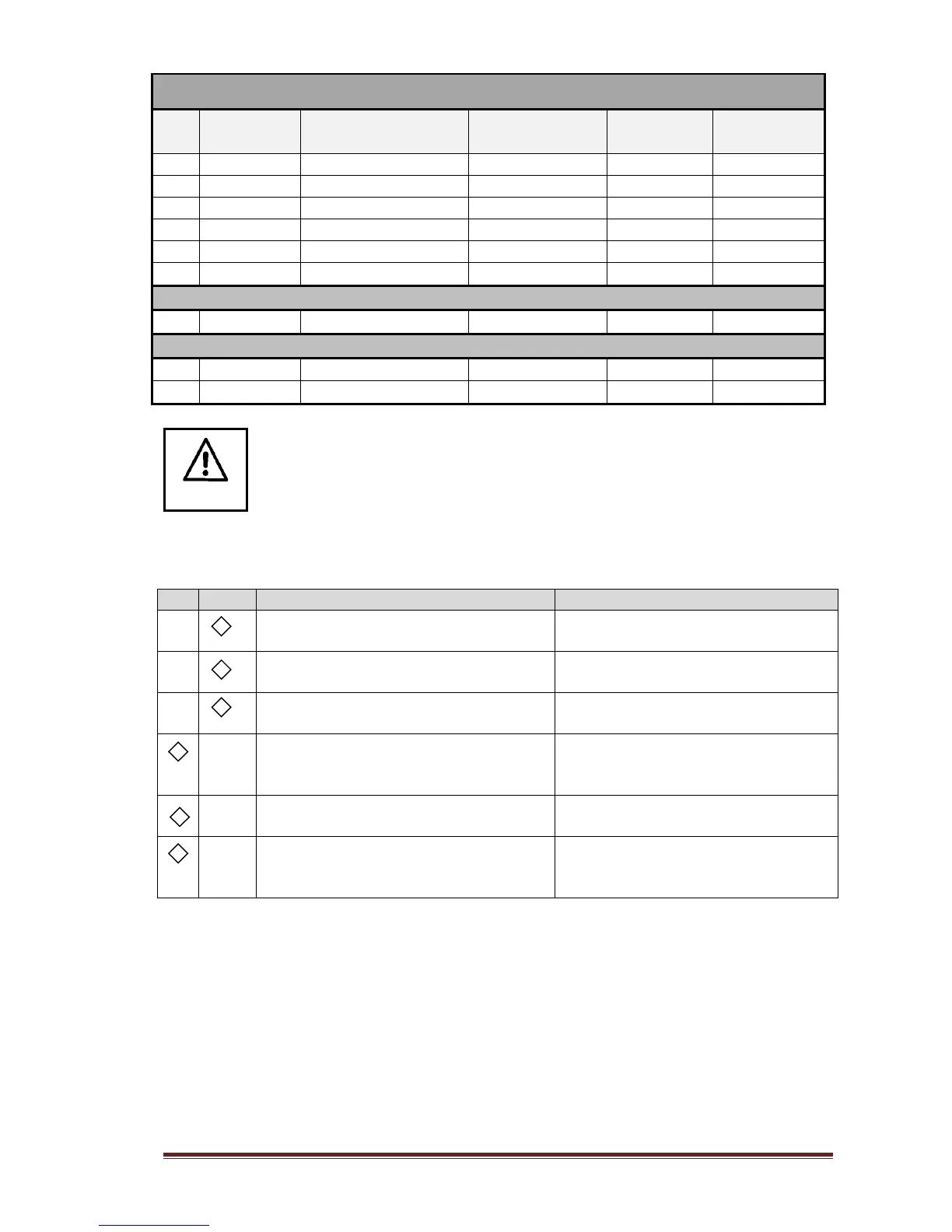

Machine Prevention

Do Don’t

Action Cause

Spray directly onto the machine with

high pressure water

Electrical shock may occurs

perate the machine with damaged or

removed fan cover

Motor will be overheated and

malfunction

Operate/keep machine with frost built

up

Flush pump with antifreeze fluids

before use.

Check hose and cord are not vehicle

run over by heavy or squeezed in door

opening

May cause machine not function

properly.

Check electrical cord and high pressure

hose for wear and cracks

To prevent electrical shock and safety

to the user

Ensure coupling parts free of dirt to

ensure long life of O-ring seals

preventing water leaks.

Extend life span of the pump seals

and maintaining correct pressure.

NOTE

Loading...

Loading...