10

FT Range SP20001_REV_2

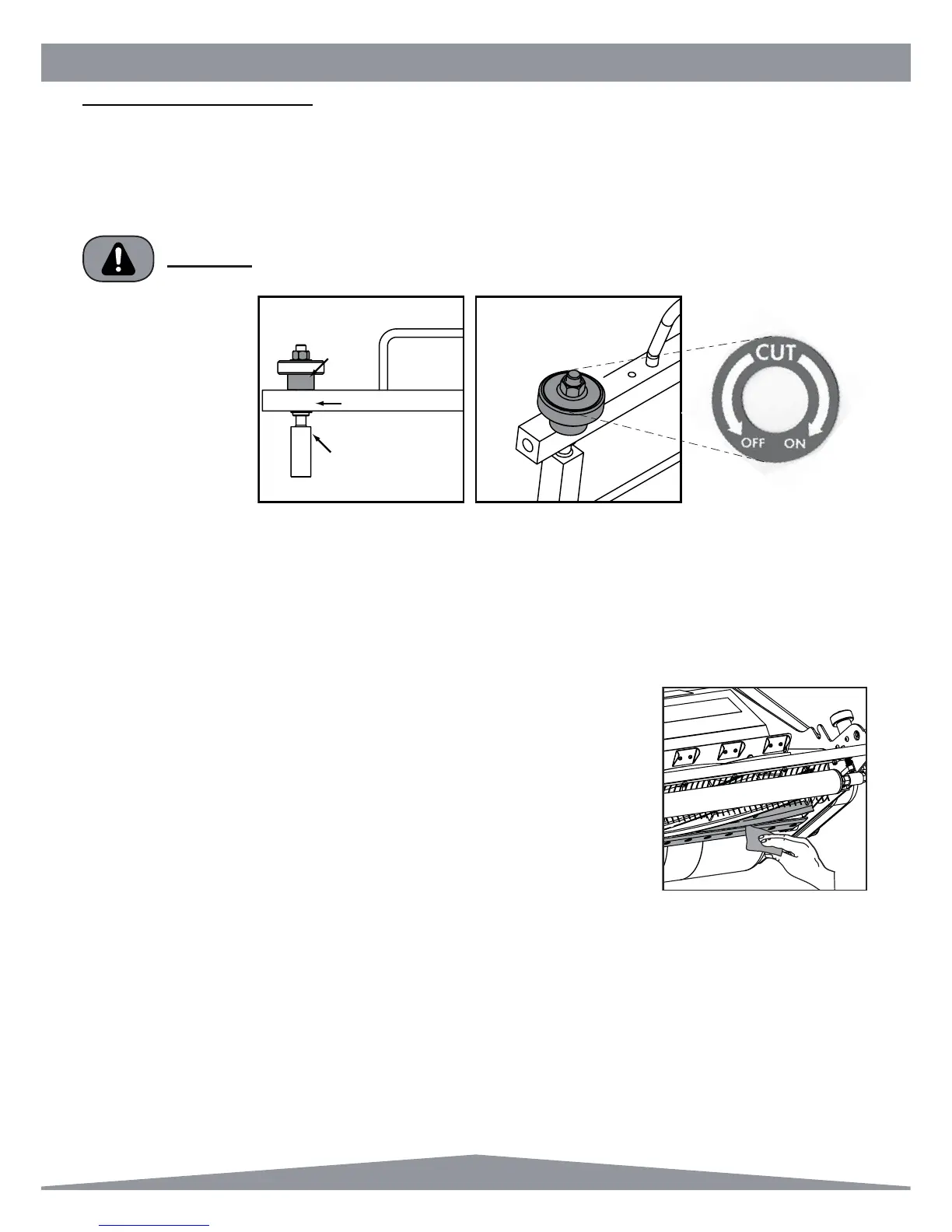

The FT cylinder is fi xed in

position in self-aligning

bearings with aluminium

housings spigotted to the

side frames. The bottom

blade assembly is

adjusted up and down by

using a knurled knob

system.

To operate this system

fi rstly slacken the two locknuts

on the adjuster stems – The Lock Nut (A) is directly on top of the Knurled Knobs (B). Use a 9/16 AF spanner. Each

knurled knob has a decal to indicate ON or OFF cut. ON cut brings the bottom blade closer to the cylinder. OFF cut

moves it away.

A = Locknut (9/16” Spanner)

B = Lubricate occasionally with Oil

C = Circlip

Rotate the knurled knobs to gain light contact between the shear blade and cylinder on

both sides of the cassette. The adjustment should be made so that the cylinder will spin

with a light audible contact with the bottom blade. Check the setting using thin paper

along the length of the cylinder adjusting until it cuts along its whole length.

When a satisfactory set is achieved tighten the lock nuts whilst holding the knurled knob

fi rmly (to stop it turning), recheck adjustment.

Do not set the cylinder hard on, as this will cause excessive wear of the cylinder, bottom

blade the drive system and increase fuel consumption.

General Adjustments

CUTTER SETTING ADJUSTMENT

For cutter cylinder cassettes (5 or 9 blade units).

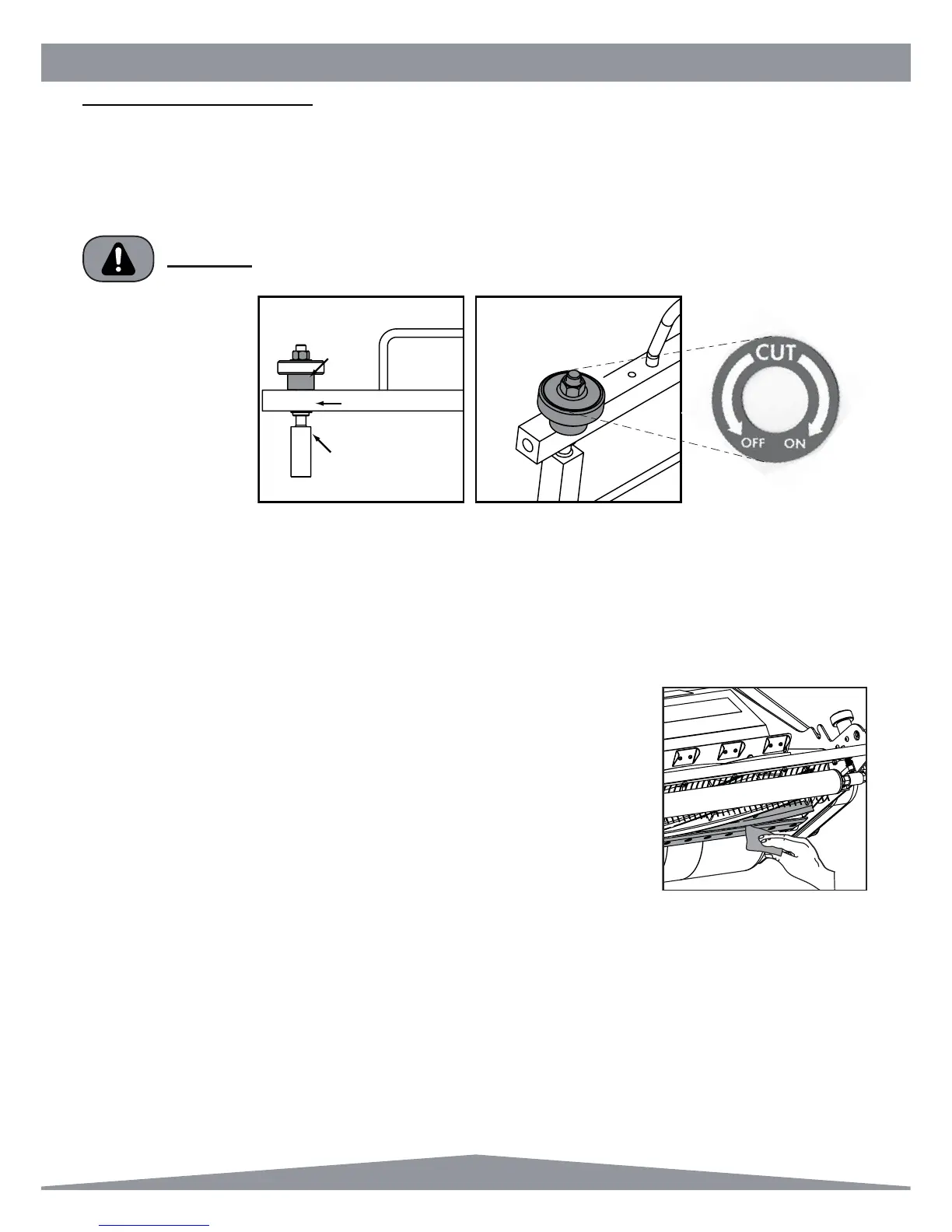

For a full view of the setting operation we suggest you remove the cassette from the machine and place on the back fl at

edge of the frame at a comfortable height. It is now possible to make adjustments in the machine without cassette

removal should you prefer.

CYLINDERS AND BOTTOM BLADES ARE SHARP, WEAR GLOVES TO PROTECT YOUR

HANDS AND FINGERS.

WARNING

Loading...

Loading...