When manual o

i

is selected, the detector is tested

either by pressing and holding the manual o

i

button

(if installed) or by shining a W867 Test Lamp into the

detector viewing windows. The “Startup and

Checkout Procedure (Manual o

i

Test)” section of this

manual explains this procedure. For problems

encountered during the manual o

i

test, refer to Table

6 - Manual o

i

Troubleshooting.

AUTOMATIC o

i

SELECTED

The Automatic o

i

feature (if selected) tests the detec-

tor approximately once each minute, checking the

cleanliness of the optical surfaces, sensor sensitivity,

and proper functioning of the electronic circuitry.

Proper operation of the detector is indicated by simul-

taneous blinking of both the UV and IR sensor LEDs

every 5 seconds. If a problem is detected for three

consecutive automatic o

i

tests, a fault signal is gen-

erated. If the detector passes three consecutive

automatic o

i

tests, the fault signal will then be

cleared. If a detector fault is indicated, observe the

detector LEDs as well as the status of the detector

relays, then refer to Tables 1 and 7 for status and

troubleshooting information.

Perform the “Startup and Checkout Procedure

(Manual o

i

Test)” in this manual to verify the proper

operation of the Fire relay and LEDs.

FIELD TESTING UV/IR DETECTORS

Det-Tronics UV/IR flame detectors contain sensitive

electronic components (ICs, transistors, etc.) that can

be damaged by electrostatic discharge (ESD).

Common causes of damage include improper han-

dling during installation/service, ground faults, power

supply transients, and lightning strikes. All Det-

Tronics systems are designed with extensive protec-

tion circuitry, however, damage can still occur.

The following field test procedure has been devel-

oped to test Det-Tronics UV/IR flame detectors for

ESD-damaged components:

1. Disable (bypass) all automatic fire extinguishing

and shutdown equipment prior to testing. If the

detector is part of a Det-Tronics controller-based

system, simply move the controller key switch to

the Test mode.

11 95-8385

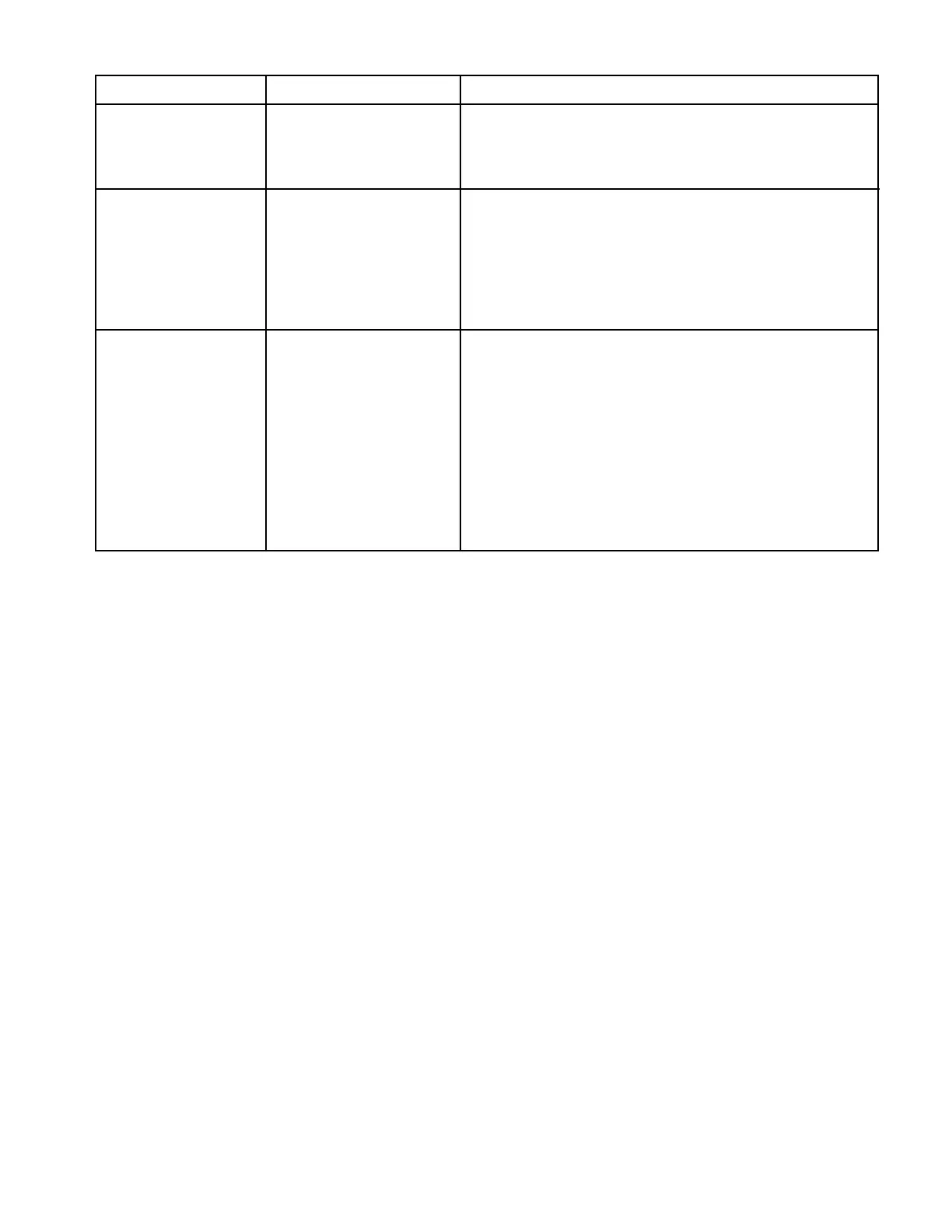

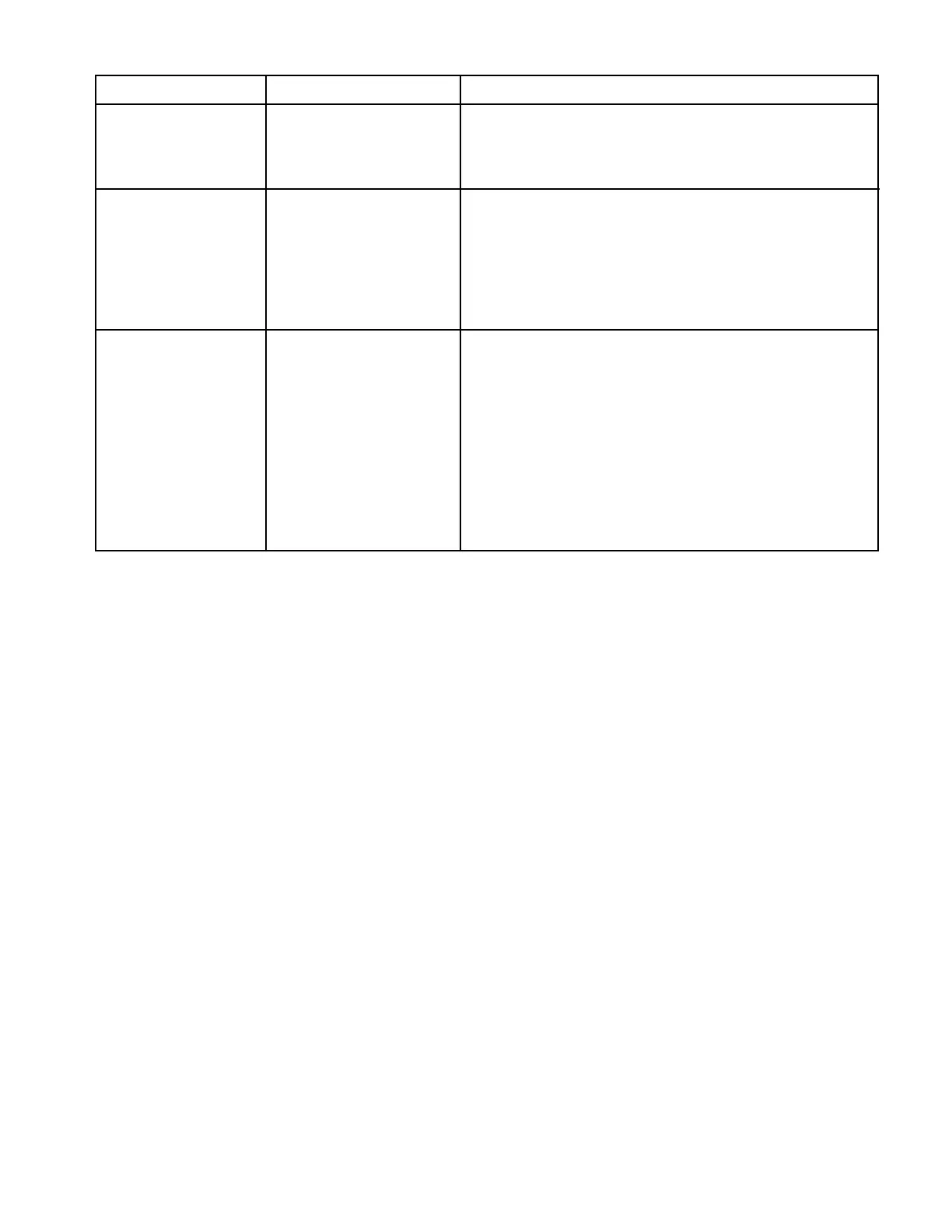

Condition Indication Corrective Action

Normal operation with Fault relay de-energized Check the operation of the power source and the

manual o

i

test not LEDs not blinking continuity of the detector wiring. If the detector appears

initiated to be “dead” with power applied, remove power and

(Manual o

i

Selected) replace the motherboard.

Manual o

i

Test Fire relay did not energize The other sensor has failed to respond.

and the LEDs of only one • Check the cleanliness of the viewing window and

sensor are illuminated repeat the test.

• If the sensor fails to respond again, replace the sensor

module.

• If the sensor still does not respond, replace the

motherboard.

Manual o

i

Test Fire relay did not energize Both sensors have failed to respond.

and the LEDs of neither • Check input power and external wiring.

sensor are illuminated • Check the cleanliness of both viewing windows.

If the detector still does not respond:

• If using a test lamp, check the battery, window, etc. to

be sure that the test lamp is working properly.

• If using the manual o

i

switch, check the switch for

proper operation and wiring.

If the detector still does not respond, replace the

motherboard.

Table 6—Manual o

i

Troubleshooting

Loading...

Loading...