Programming Manual

PC 2003 Amplifier

English

Page 9/14

PROPC2003EN – Index A

Here is an example to get a better understanding of this function:

Everything depends on the station which the machine feeds and where the

sensor is positioned.

For our example, let’s take a TORNOS AS14 (6 spindles) machine and place the

sensor between spindles 5 and 6:

The feeding takes place at station 6, and at the same time the feed information is

sent to the amplifier. From then on, the electronic box is going to count down the

number of measurements in order to mask the measurement of the fed part which

will be short. Therefore, the 6

th

measurement after the masking pulse (feed

information) has to be masked and so the amplifier has to be programmed FOR 6

MEASUREMENTS.

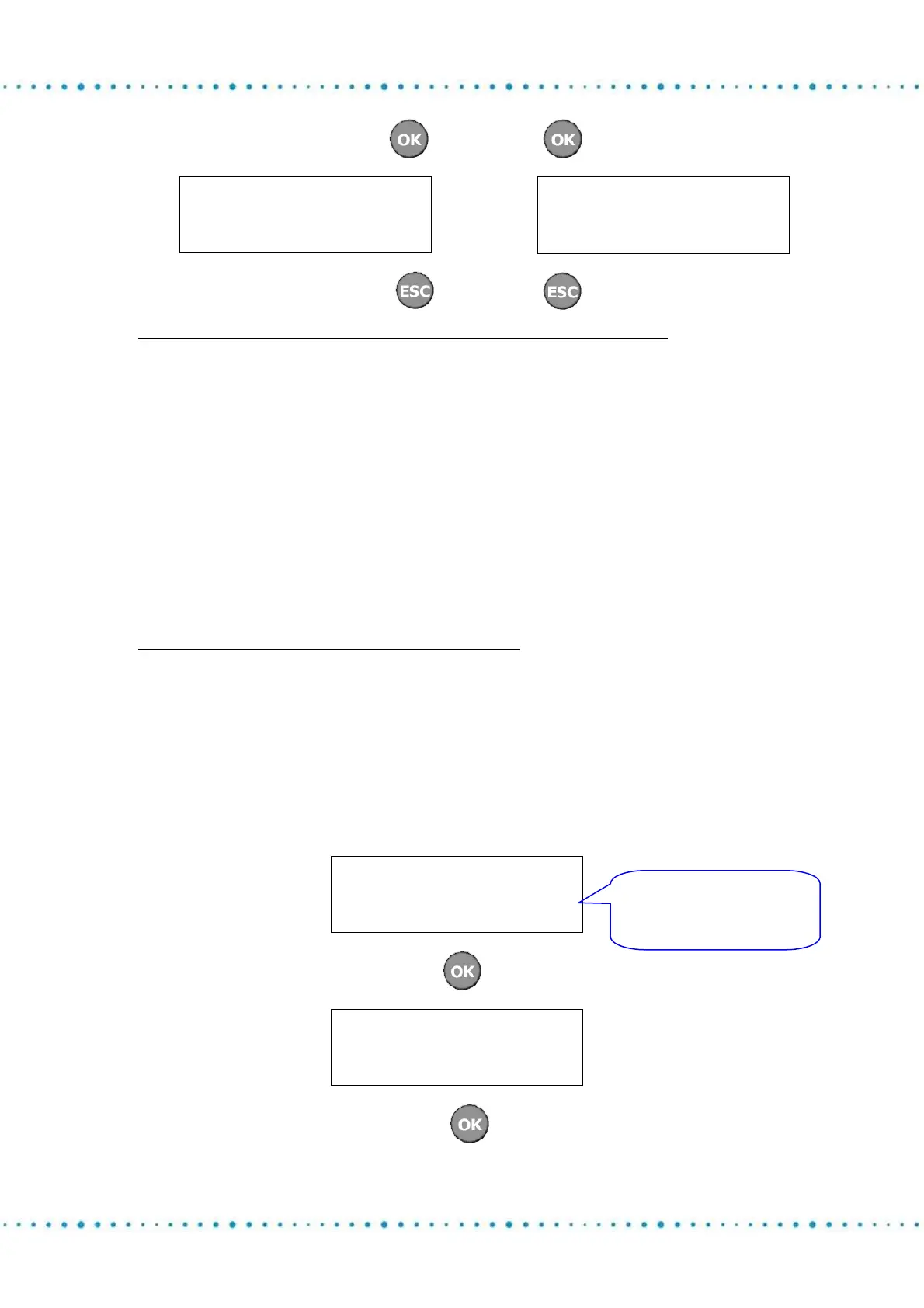

3.2 Transferring a measurement

Transferring a measurement’s processing consists of offsetting a relay’s fault

state to the desired station. An immediate action after a part is detected outside

tolerance is not always practical for its removal. Therefore, this function allows

triggering the machine shutdown relay when the bad part is accessible, such as

when it is located in the pickoff spindle.

This function can be INACTIVE or ACTIVE after n measurements (1 to 25

maximum).

CHAN 1 : +0.000mm

CHAN 2 : +0.000mm

V

V

MEASURE

->

OPTIONS

PARAMETERS

DISPLAYS

V

V

V

V

->

MEASURE MASKING

ACTION DELAY

MULTI-PART ACTION

V

X2

V

V

MEASURE MASKING

->

CHANNEL 1

CHANNEL 2

V

X3

appears only if

you have a PC2003B

(dual channel) device.

Loading...

Loading...