Page 6 SB-2-630

TROUBLESHOOTING (continued)

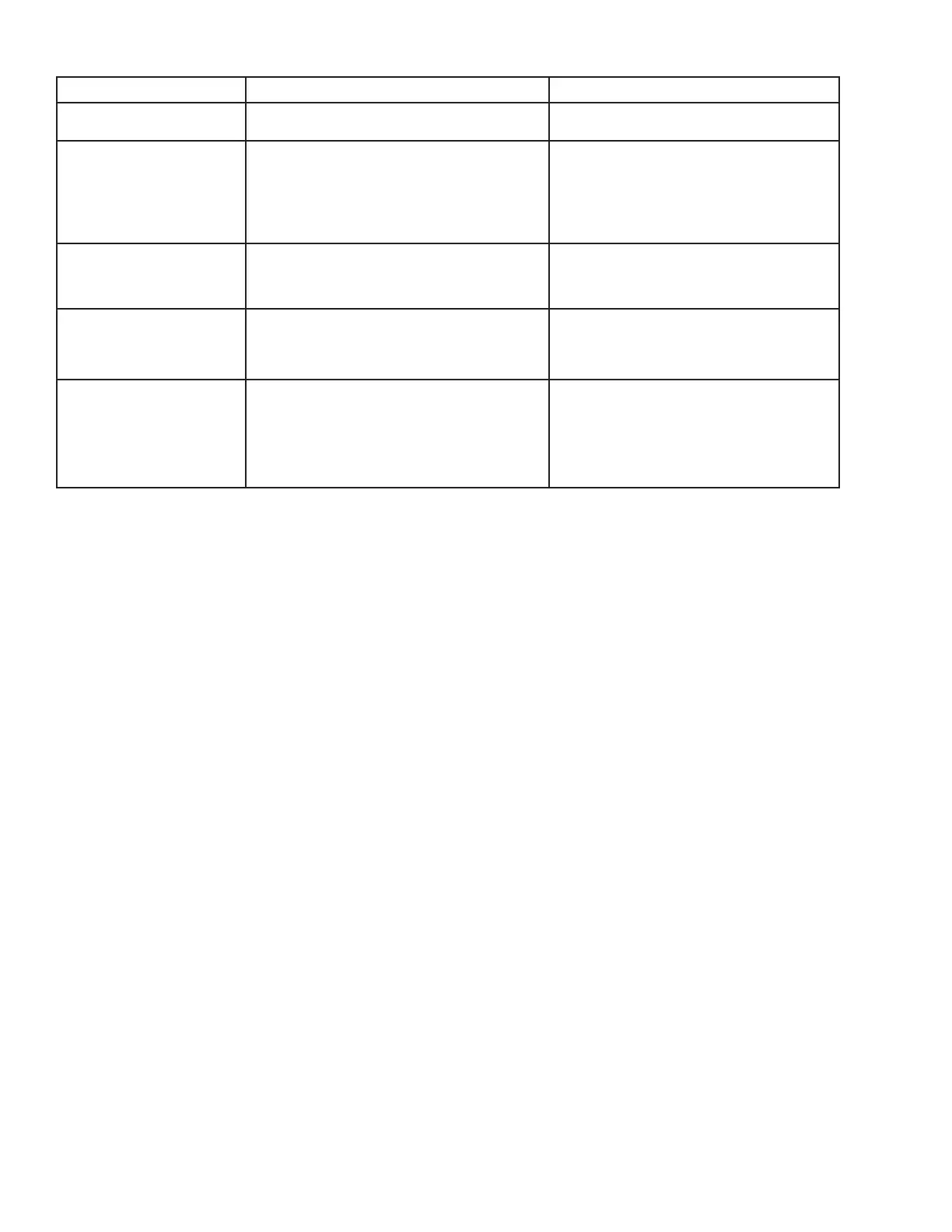

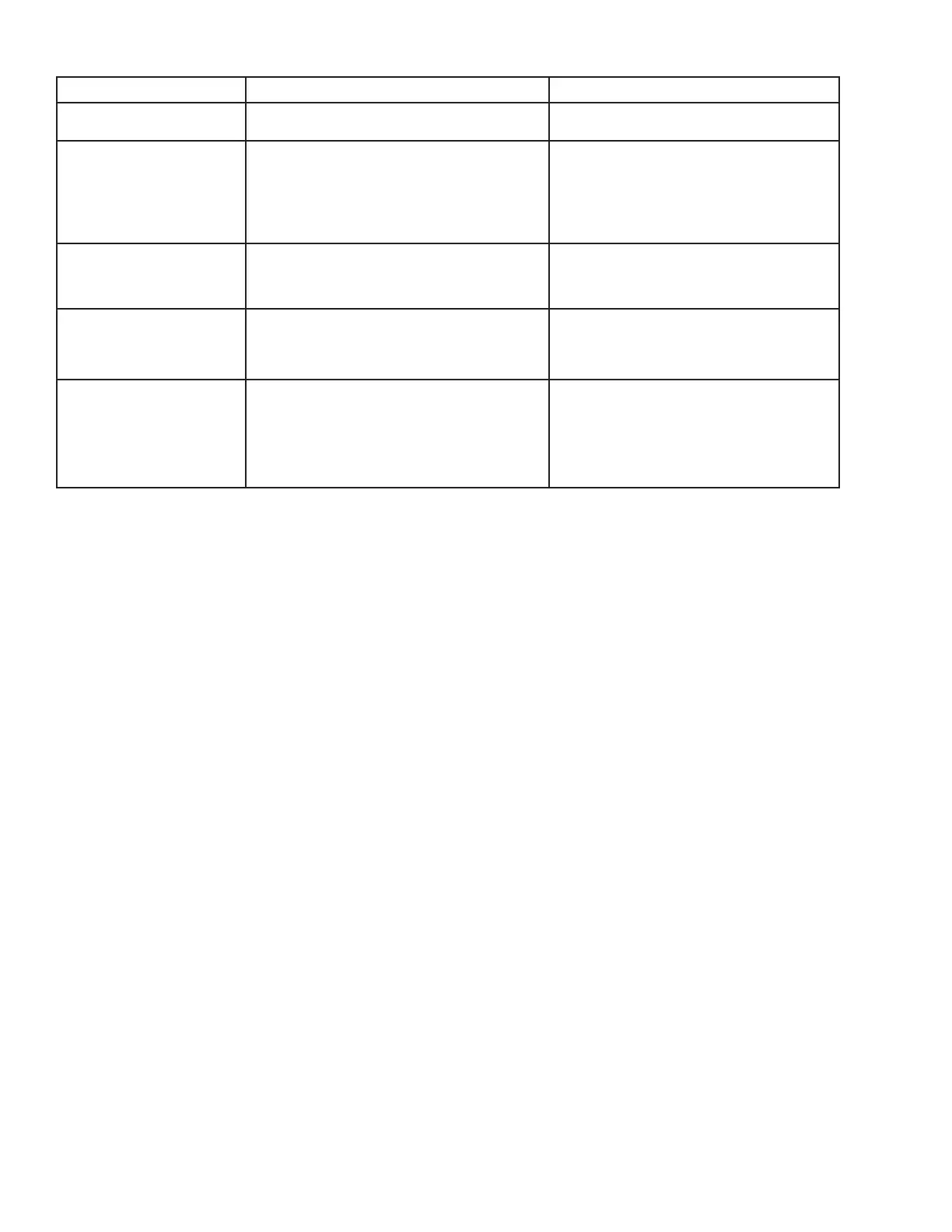

CONDITION CAUSE CORRECTION

Fluid leaking from packing nut Packing nut loose. Tighten, do not bind needle.

Packing worn or dry. Replace or lubricate.

Fluid leaking or dripping from Packing nut too tight. Adjust

front of gun

Dry packing. Lubricate.

Fluid tip or needle worn or damaged. Replace tip & needle.

Foreign matter in tip. Clean.

Fluid needle spring broken. Replace.

Wrong size needle or tip. Replace.

Runs and sags Too much material flow. Adjust gun or reduce tip size.

Material to thin. Mix properly or apply light coats.

Gun tilted on an angle or gun motion too slow. Hold gun at right angle to work and adapt to

proper gun technique

Thin, sandy coarse finish Gun too far from surface. Check distance. Normally 6-8".

drying before it flows out

Too much air pressure. Reduce air pressure and check spray pattern.

Improper thinner being used. Follow paint manufacturer's mixing instructions.

Thick, dimpled finish "orange Gun too close to surface. Check distance. Normally 6-8".

peel". Too much material coarsely atomized. Turn in fluid adjusting screw or change to a

smaller tip size.

Air pressure too low. Increase air pressure or reduce fluid flow.

Improper thinner being used. Follow paint manufacturer's mixing instructions.

Material not properly mixed. Follow paint manufacturer's mixing instructions.

Surface rough, oily, dirty. Properly clean and prepare.

Loading...

Loading...