Reduce fluid flow by turning fluid

needle adjusting screw

clockwise. Reduce fluid pressure.

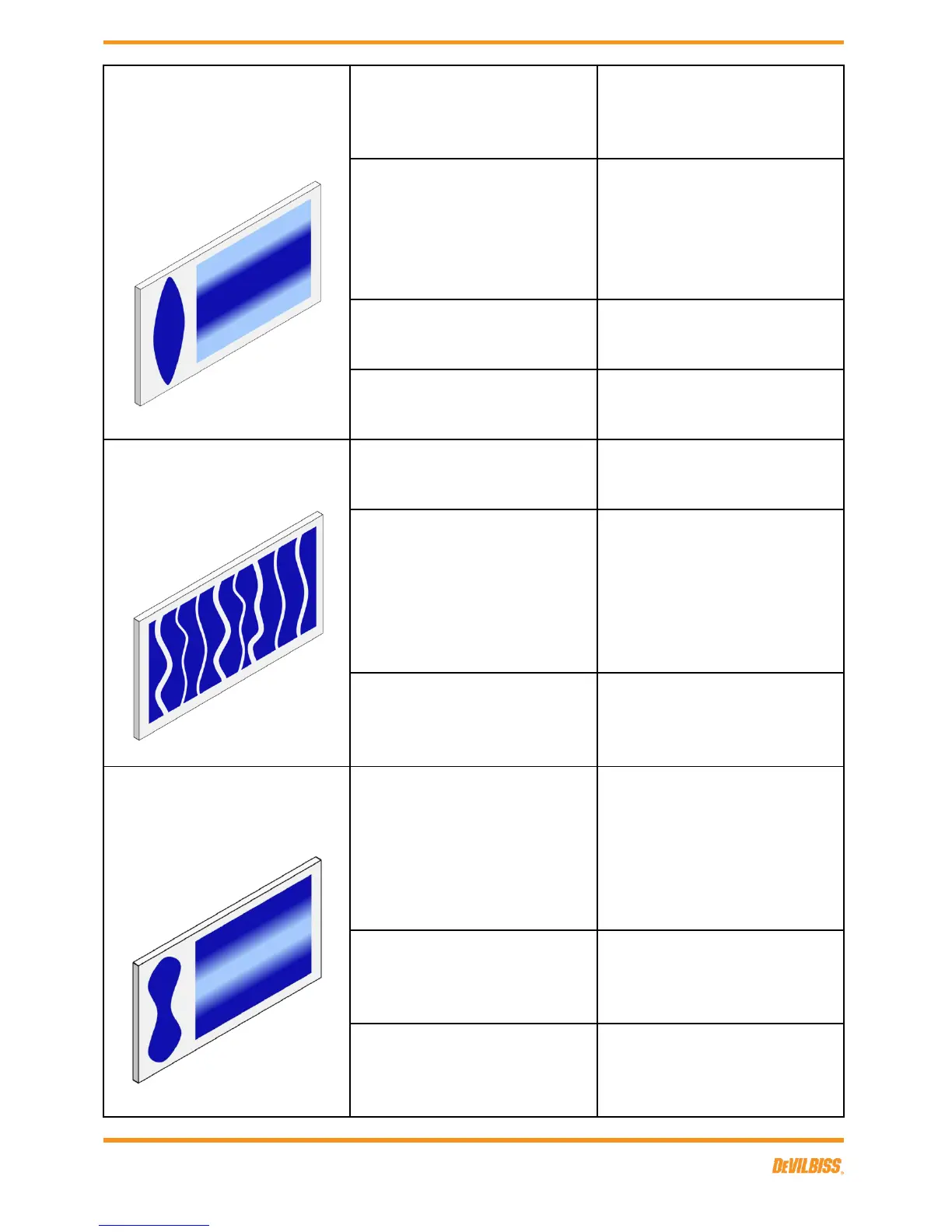

Pattern adjustment valve set too

low.

Turn out counter clockwise to

achieve correct pattern.

Reduce input air pressure.

Atomising air pressure too low.

Reduce air pressure by rotating

pattern control valve clockwise.

Too much air for fluid quanitity

used.

Fluid tip not seated correctly in

gun head.

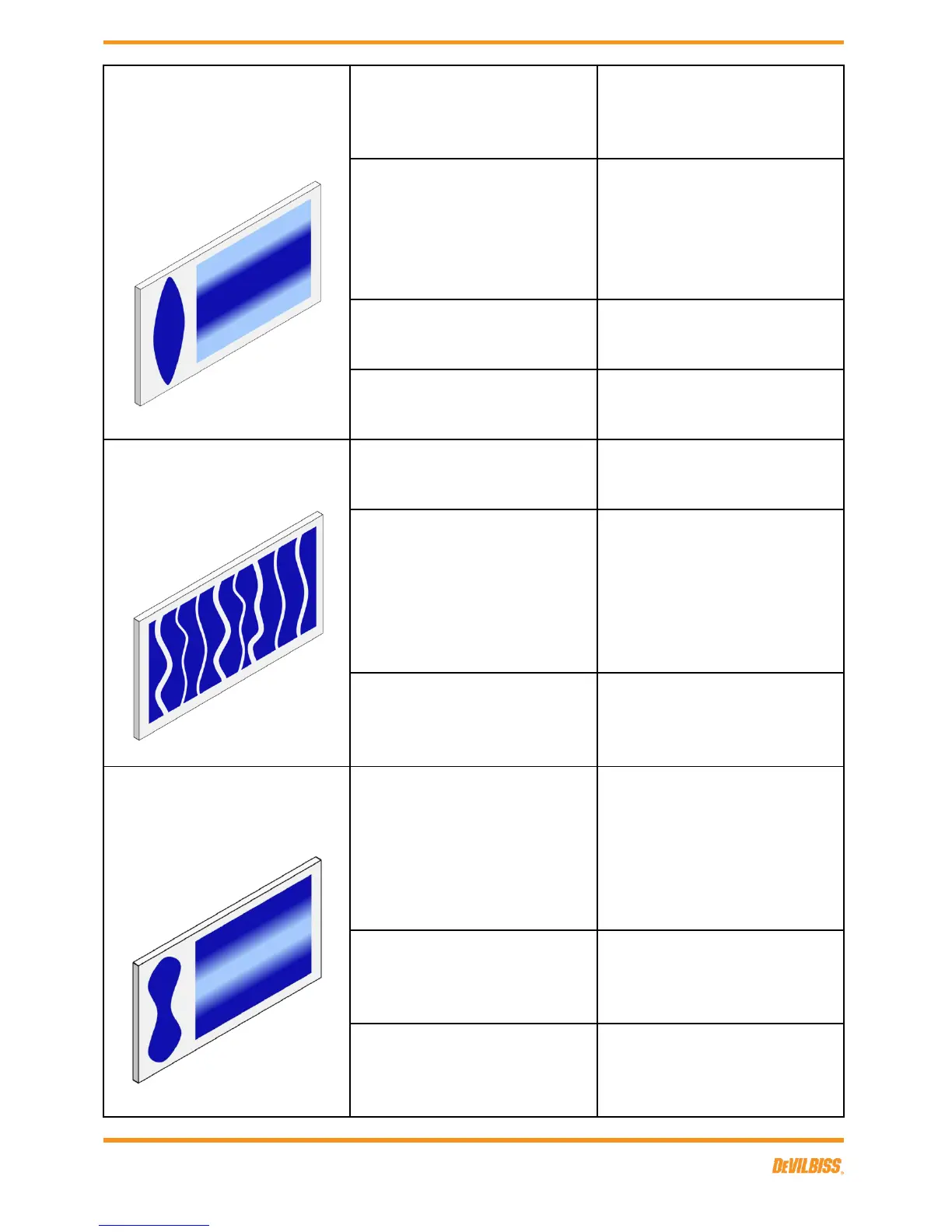

Not enough material flow.

Thin to correct consistency.

Partially obstructed fluid passage

or hose.

Remove fluid tip, clean

components, check cone seating

on tip and gun for damage or

contamination.

Increase fluid flow by changing fluid

tip size, opening needle control knob

or increase fluid pressure on

pressure feed container.

Intermittent or 'fluttering'

spray fan.

Loading...

Loading...