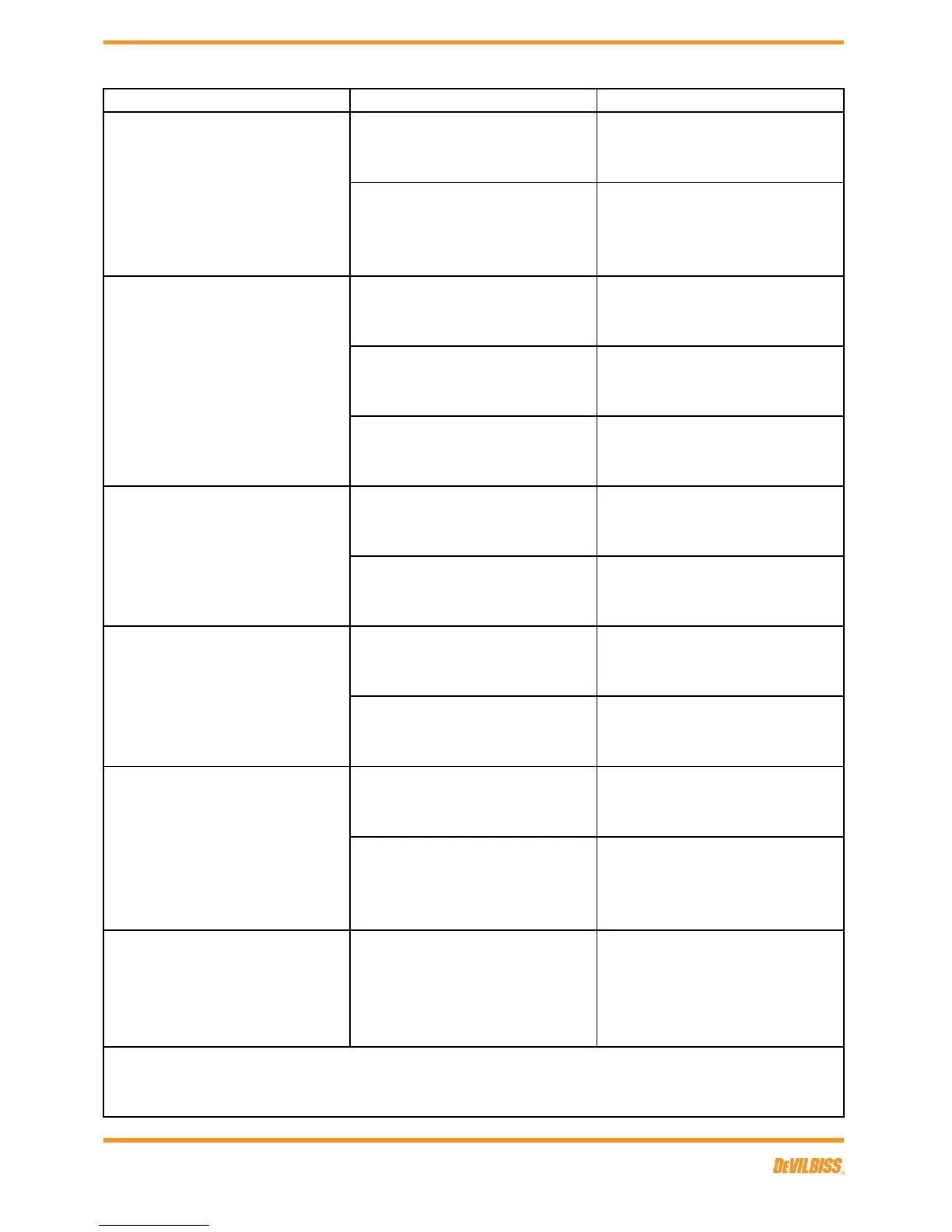

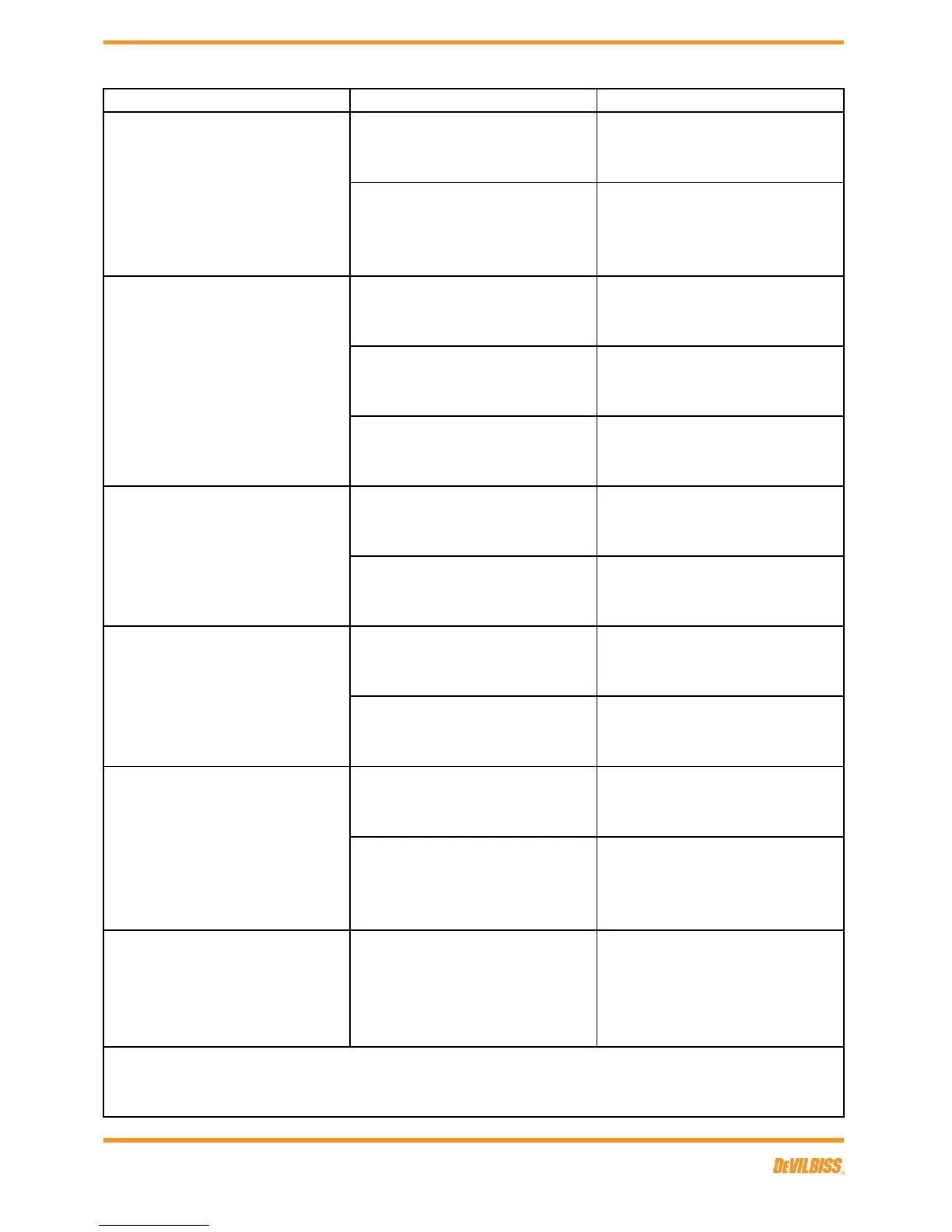

Fluid tip or sprayhead incorrectly

fitted.

Remove, check components for

damage and refit correctly.

When removing air cap from retaining ring, do not remove the ring seat from the retaining ring.

Damage to the parts may occur. Simply wipe parts clean and reassemble with new or clean air cap.

Fluid tip not fitted correctly in

gun head.

Check for damage or blockage.

Paint build-up on fluid tip.

Fluid tip not fitted correctly in

gun head.

Fluid tip/needle leakage.

Check for damage or blockage.

Paint build-up on air cap.

Replace with new air cap.

Gradual build-up of bounce-back

on gun head.

Gun spits paint when triggering

on due to paint build-up inside air

cap between spraying operations.

TROUBLESHOOTING MECHANICAL PERFORMANCE

Unable to get round spray

Fluid tip/needle leakage.

Check air supply and air line.

Fluid needle adjustment knob not

open enough.

Open fluid needle adjustment

knob.

Gun spits paint when triggering

on and off.

Incorrect needle fitted to gun.

Check fluid tip/needle selection

chart and fit correct item.

Excessive fluid tip wear.

Replace with new fluid tip.

Loading...

Loading...