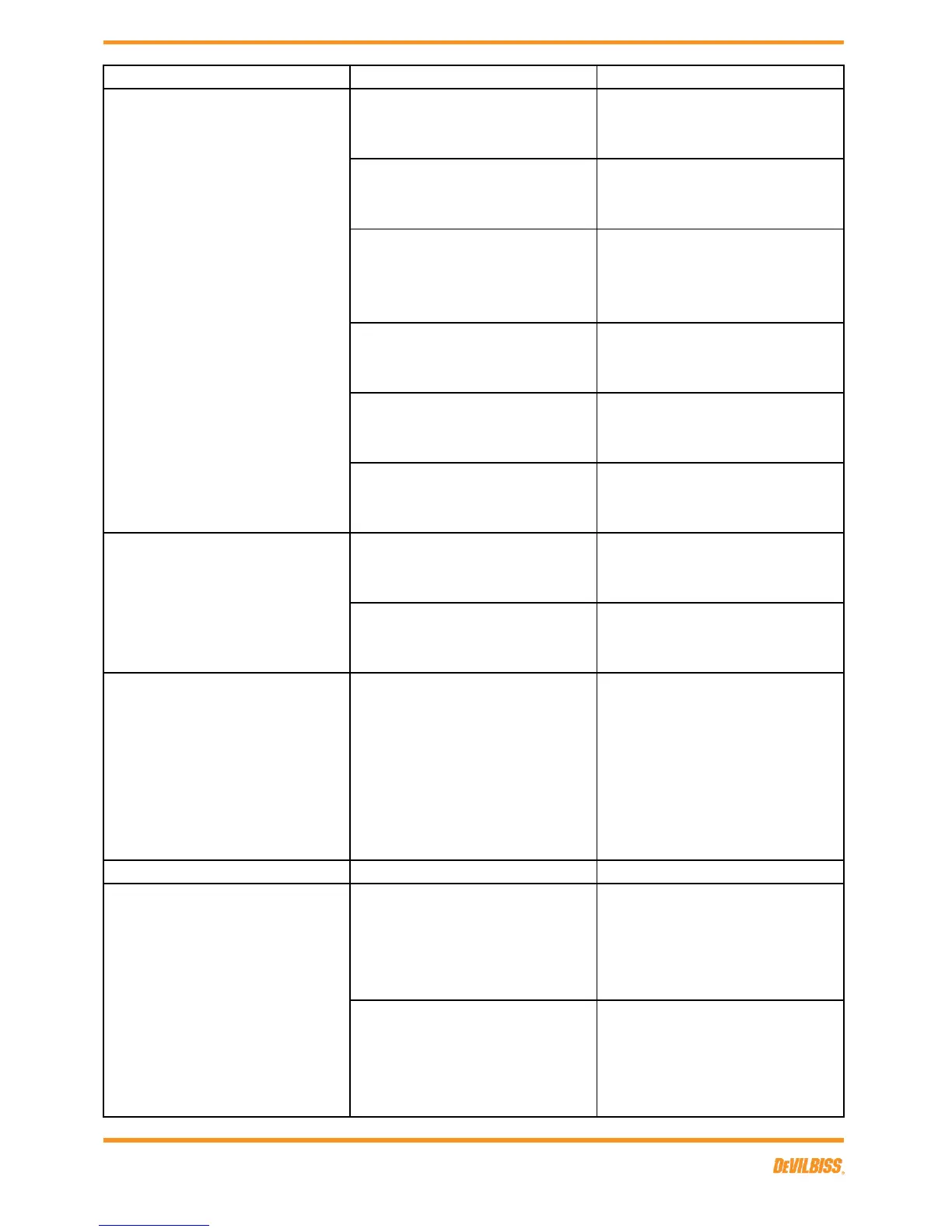

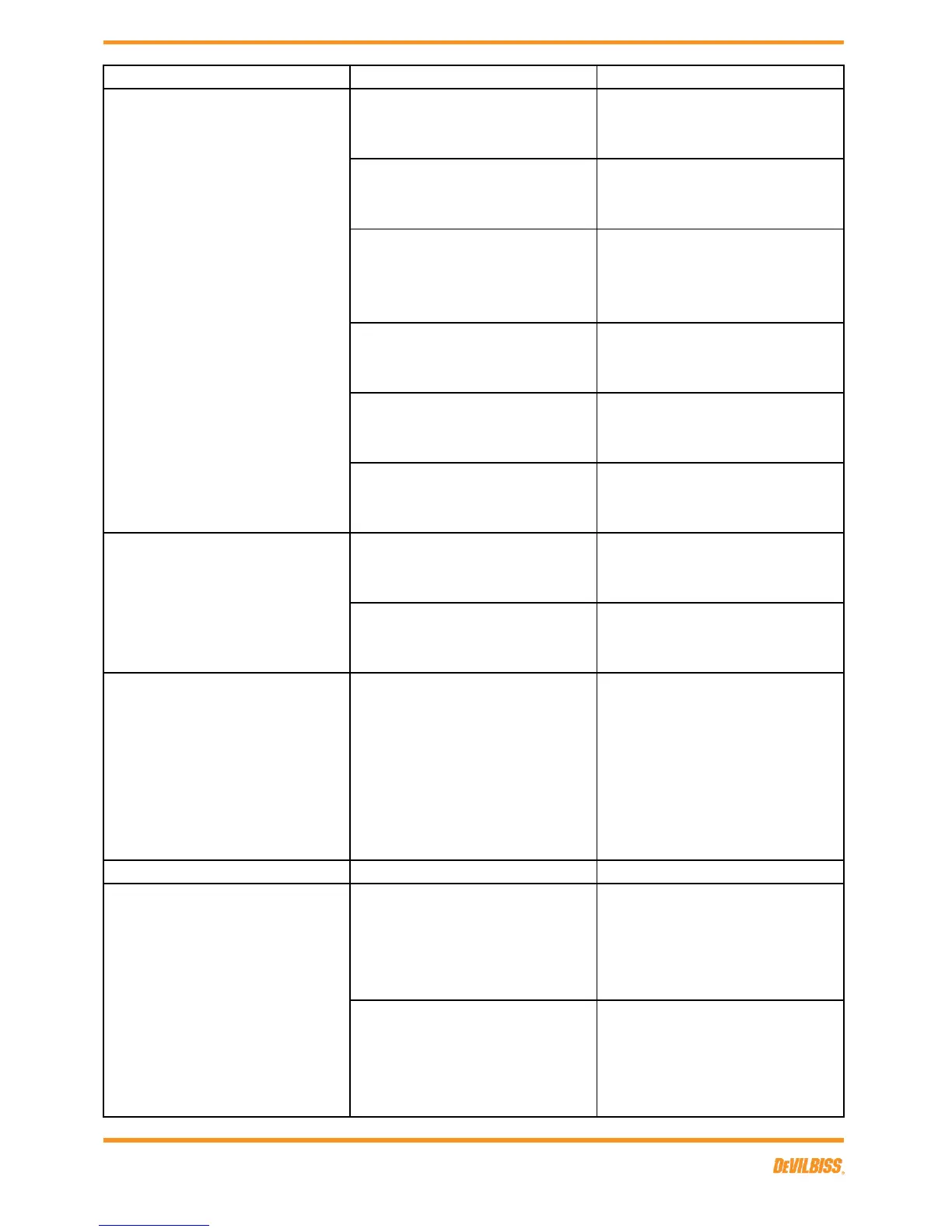

Fluid needle external profile

damaged or worn.

Slow fluid leak from fluid tip and

needle seat.

Incorrect fluid tip for fluid needle

fitted to gun.

Check tiip/needle selection chart

and fit correct item.

Major fluid leak or fluid jetting

from fluid tip and needle seat.

Remove tip and needle and

thoroughly clean.

Contamination on needle or tip

mating surfaces preventing good

seal.

Spindle contaminated and not

correctly seating.

Fluid tip internal seat scored

damaged or worn.

Tighten or replace as necesarry.

Fluid needle packing worn or

loose.

Slow fluid leak from needle

packing.

Small air leak from air cap when

gun is not triggered.

Remove spindle and thoroughly

clean valve shaft and seating

surfaces.

Spindle seal damaged or missing.

Incorrect fluid tip for fluid needle

fitted to gun.

Check tiip/needle selection chart

and fit correct item.

Contamination on needle or tip

mating surfaces preventing good

seal.

Loading...

Loading...