11

ENGLISH

any of the accuracy checks listed in this manual, follow

theseguidelines:

• Use the largest area/distance possible, closest to the

operating distance. The greater the area/distance, the

easier to measure the accuracy of thelaser.

• Place the laser on asmooth, flat, stable surface that is

level in bothdirections.

• Mark the center of the laserbeam.

Using the Laser

Leveling the Laser

As long as the laser is properly calibrated, the laser is

self-leveling. Each laser is calibrated at the factory to find

level as long as it is positioned on a flat surface within

average ± 4° of level. No manual adjustments arerequired.

If the laser has been tilted so much that it cannot self-level

(> 4°), the laser beam will flash. There are two flashing

sequences associated with the out-of-levelcondition.

Using the Pivot Bracket (Fig.I, J, M)

The laser has a magnetic pivot bracket

6

permanently

attached to theunit.

WARNING: Position the laser and/or wall mount on

astable surface. Serious personal injury or damage to

the laser may result if the laserfalls.

• The bracket has a keyhole slot

7

so it can be hung from

a nail or screw on any kind ofsurface.

• The bracket has magnets

12

which allow the unit to

be mounted to most upright surfaces made of steel or

iron. Common examples of suitable surfaces include

steel framing studs, steel door frames, and structural

steel beams. Before attaching the pivot bracket against a

stud

13

, place the Metal Enhancement Plate

14

on the

opposite side of thestud.

• The bracket has tripod threads

11

on the bottom, so it

can be mounted to a tripod and placed where need.

Field Calibration Check

Checking Accuracy – Horizontal Beam,

Scan Direction (Fig. F)

Checking the horizontal scan calibration of the laser requires

two walls at least 30' (9 m) apart. It is important to conduct

a calibration check using a distance no shorter than the

distance of the applications for which the tool will beused.

1. Attach the laser to a wall using its pivot bracket. Make

sure the laser is facing straightahead.

2. Turn on the laser's horizontal beam and pivot the laser

approximately 45˚ so that the rightmost end of the laser

line is striking the opposing wall at a distance of at least

30' (9 m). Mark the center of the beam (a).

3. Pivot the laser approximately 90˚ to bring the leftmost

end of the laser line around to the mark made in Step 2.

Mark the center of the beam (b).

4. Measure the vertical distance between themarks.

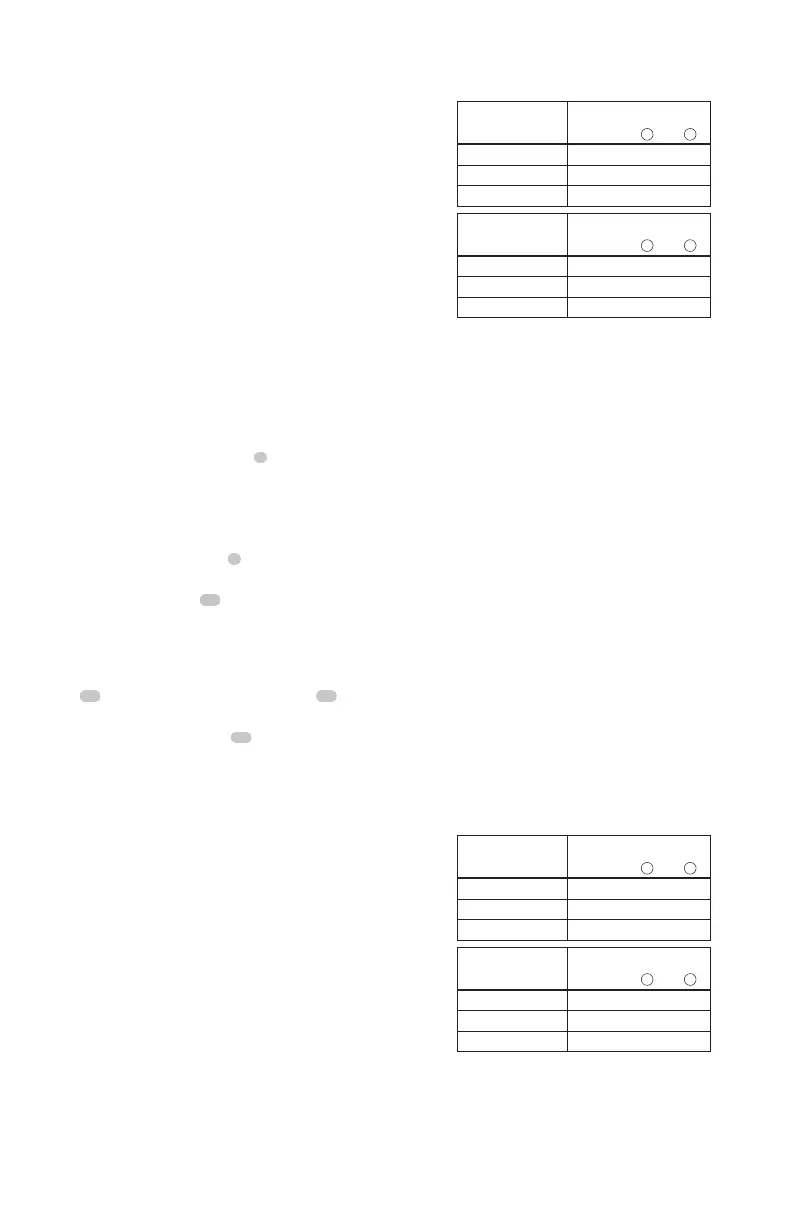

• If the measurement is greater than the values shown

below, the laser must be serviced at an authorized

servicecenter.

Distance

Between Walls

Allowable Distance

Between

a

and

b

30' 1/8"

40' 5/32"

50' 7/32"

Distance

Between Walls

Allowable Distance

Between

a

and

b

9.0 m 3.1 mm

12.0 m 4.2 mm

15.0 m 5.2 mm

Checking Accuracy – Horizontal Beam,

Pitch Direction (Fig. G)

Checking the horizontal pitch calibration of the laser requires

a single wall at least 30' (9 m) long. It is important to conduct

a calibration check using a distance no shorter than the

distance of the applications for which the tool will beused.

1. Attach the laser to one end of a wall using its

pivotbracket.

2. Turn on the laser's horizontal beam and pivot the laser

toward the opposite end of the wall and approximately

parallel to the adjacentwall.

3. Mark the center of the beam at two locations (a, b) at

least 30' (9 m)apart.

4. Reposition the laser to the opposite end of thewall.

5. Turn on the laser's horizontal beam and pivot the laser

back toward the first end of the wall and approximately

parallel to the adjacentwall.

6. Adjust the height of the laser so that the center of the

beam is aligned with the nearest mark (b).

7. Mark the center of the beam (c) directly above or below

the farthest mark (a).

8. Measure the distance between these two marks(a,c).

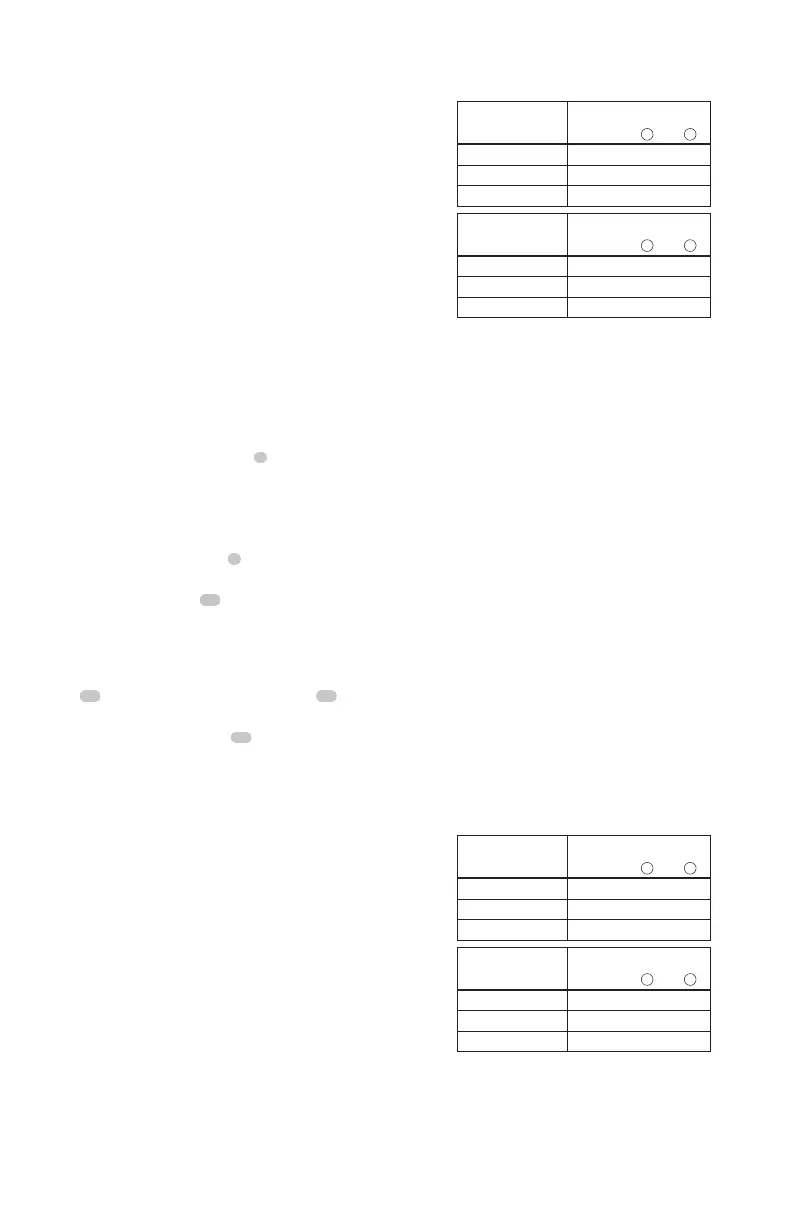

• If the measurement is greater than the values shown

below, the laser must be serviced at an authorized

servicecenter.

Distance

Between Walls

Allowable Distance

Between

a

and

c

30' 1/4"

40' 5/16"

50' 13/32"

Distance

Between Walls

Allowable Distance

Between

a

and

c

9.0 m 6.2 mm

12.0 m 8.3 mm

15.0 m 10.4 mm

Checking Accuracy – Vertical Beam (Fig. H)

Checking the vertical (plumb) calibration of the laser can be

most accurately done when there is a substantial amount of

vertical height available, ideally 20' (6m), with one person

on the floor positioning the laser and another person near

a ceiling to mark the position of the beam. It is important

Loading...

Loading...