ENGLISH

8

ASSEMBLY AND ADJUSTMENTS

WARNING: To reduce the risk of serious personal

injury, turn unit off and remove the battery pack

before making any adjustments or removing/

installing attachments or accessories. An

accidental start‑up can causeinjury.

Remove and Replace Parts (Fig. D, E)

Removing the Shear Head Assembly

(Fig. D)

1. To remove shear head assembly

2

from motor, loosen

3 cap screws

10

.

2. Remove shear head assembly by pulling head firmly

forward. Slight twisting action may be required if head

does not slide offeasily.

Removing the Cutter Blades (Fig. D, E)

1. To remove cutter blades from shear head assembly,

remove 3 cap screws

10

from shear housing with the

provided hex wrench

3

. Be careful not to lose rear

spacer bushing when removing middle capscrew.

2. Remove center blade

13

from housing by tapping

blade gently towards the rear. Side knife

12

and side

spacers

9

will now drop out of thehousing.

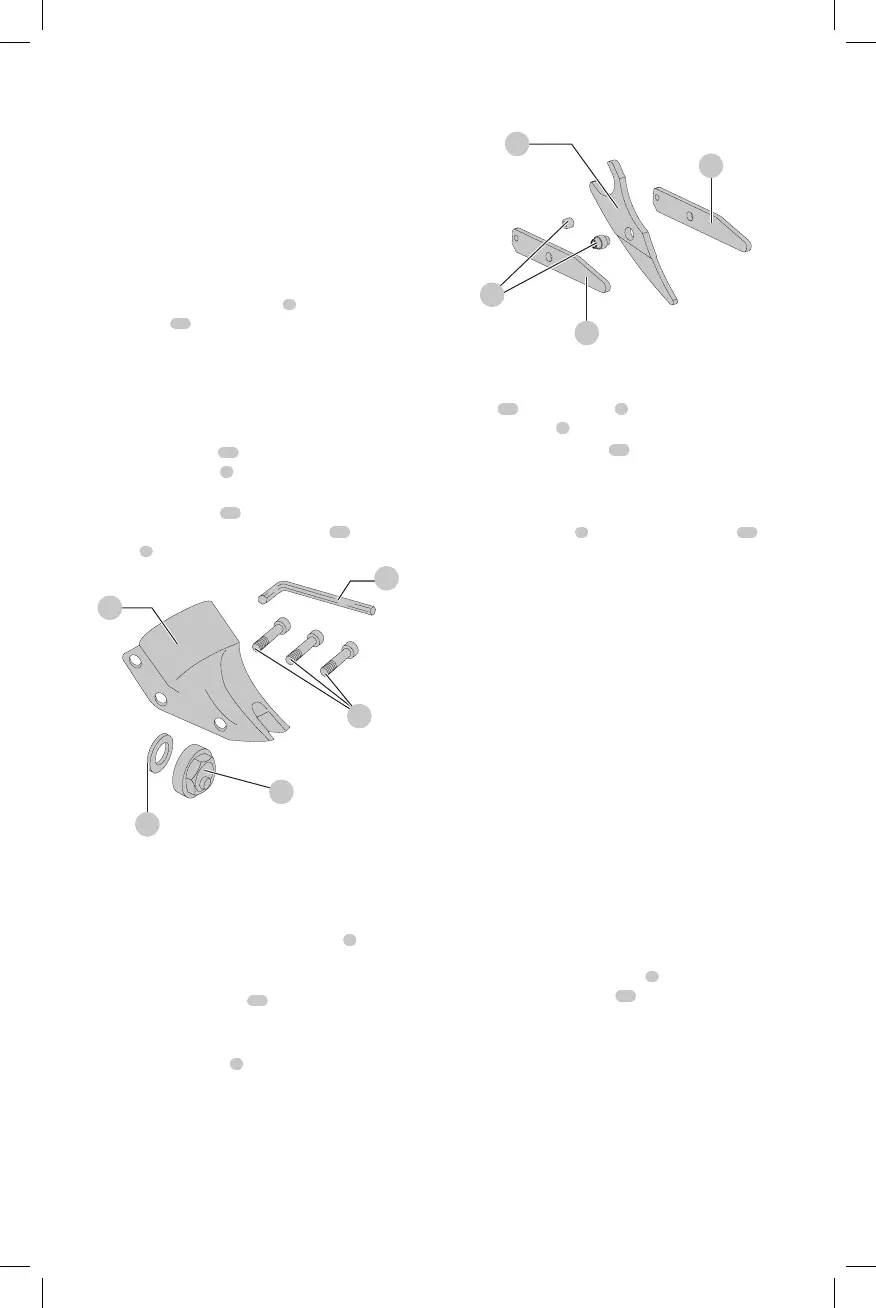

Fig. D

2

10

11

8

3

Removing and Replacing the Eccentric

Bearing Assembly (Fig. D)

To remove eccentric bearing assembly from shaft, use

an appropriate wrench to loosen eccentric nut

8

by

turningcounterclockwise.

1. To install eccentric bearing assembly onto shaft, make

sure the large thin washer

11

is first inserted overshaft.

2. Screw eccentric bearing assembly onto shaft and

tighten with appropriatewrench.

3. Lubricate eccentric nut

8

with a good grade of

bearinggrease.

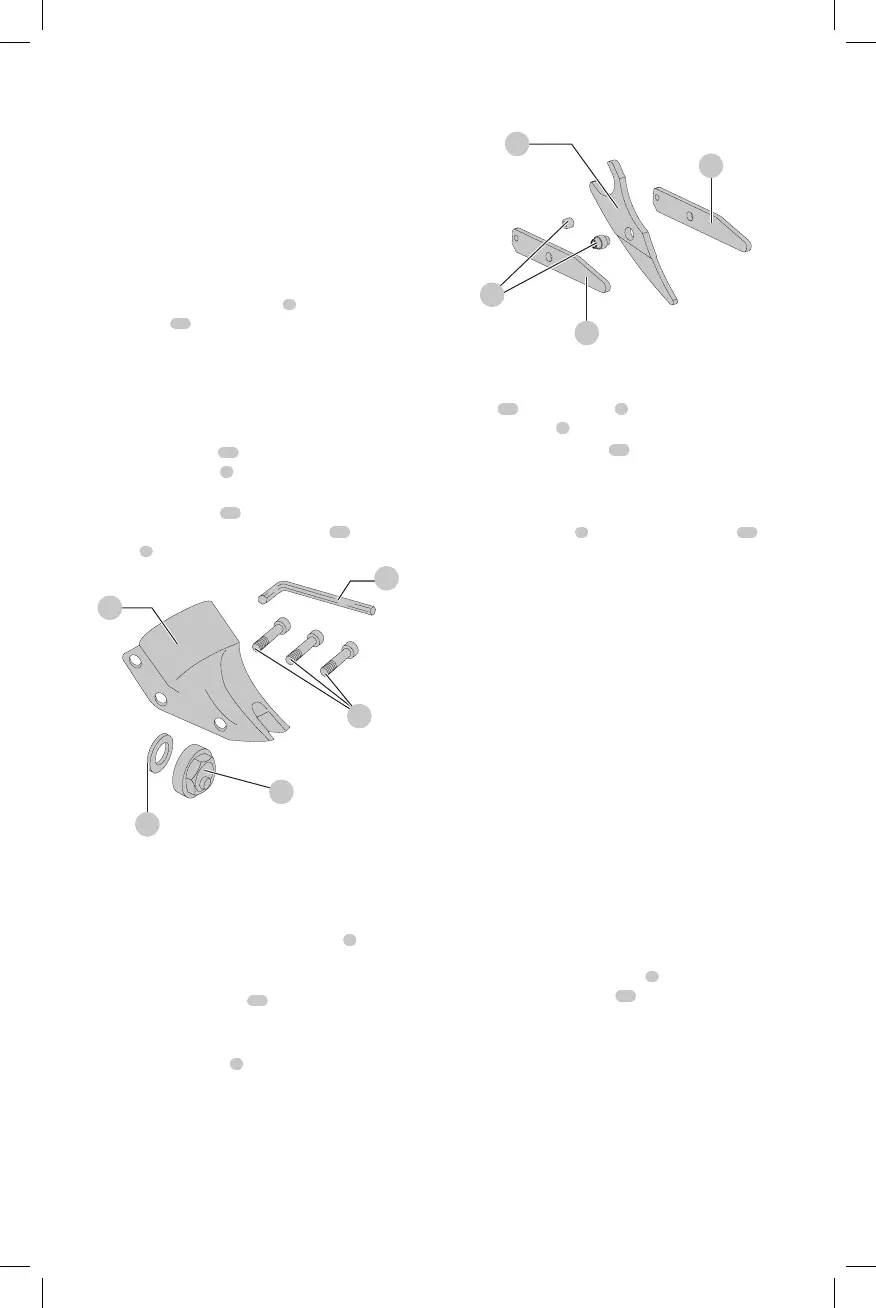

Fig. E

9

12

12

13

Installing the Cutter Blades (Fig. D, E)

1. To install cutter blades into shear housing, place the side

knife

12

and side spacer

9

into position in the shear

head assembly

2

.

2. Insert center cap screws

10

through side knife and side

spacer with rear spacer bushing betweenthem.

3. Start cap screw into thread just enough to hold blades

in place. DO NOTTIGHTEN.

4. Insert side spacers

9

into hole in center blade

13

andlubricate.

5. Install center blade into shear housing by tapping blade

gently forward using a drift to line up hole in center

blade with forward holes in housing. Insert and tighten

forward cap screw making sure spacer bushing in center

blade stays inposition.

6. Apply good grade of bearing grease to clevis or yoke

in center blade where it rides on the eccentric bearing

assembly. Insert rear cap screw into shear housing but

do not completelytighten.

NOTE: Change the side knives after they show a width wear

pattern of 50%. Swap the knives left to right and use them

until the patterns meet. When the patterns meet, invert the

left and right side knives and use them until they show a

width wear pattern of 50%. They can then be swapped from

left to right until you use all 4 sides of the blades. Never

exceed 10000 feet of cutting on a set of side knives. The tool

will continue to cut after these landmarks are reached, but

the power unit will becomeoverloaded.

Installing the Shear Head Assembly

(Fig. D)

1. To install shear head assembly

2

onto drive motor,

make sure all cap screws

10

are loosened about 3 or 4

completeturns.

2. Place shear head onto unit and alternately tighten cap

screws snugly to lock head assembly in place. It may be

necessary to gently tap the shear head into place if it

does not readily slip onto the nose of the powerunit.

3. Tighten all three cap screws to 45–50 in‑lbs.

(5.08‑5.64Nm). Failure to tighten the cap screws

properly can cause the cap screws tobreak.

Loading...

Loading...