If

by any

chance

the

blade

does

not lie

flat against

the

fence then return

it to the 0°

cross-cut position

and

repeat

the

above adjustment procedure (making

blade parallel

to arm

tracks).

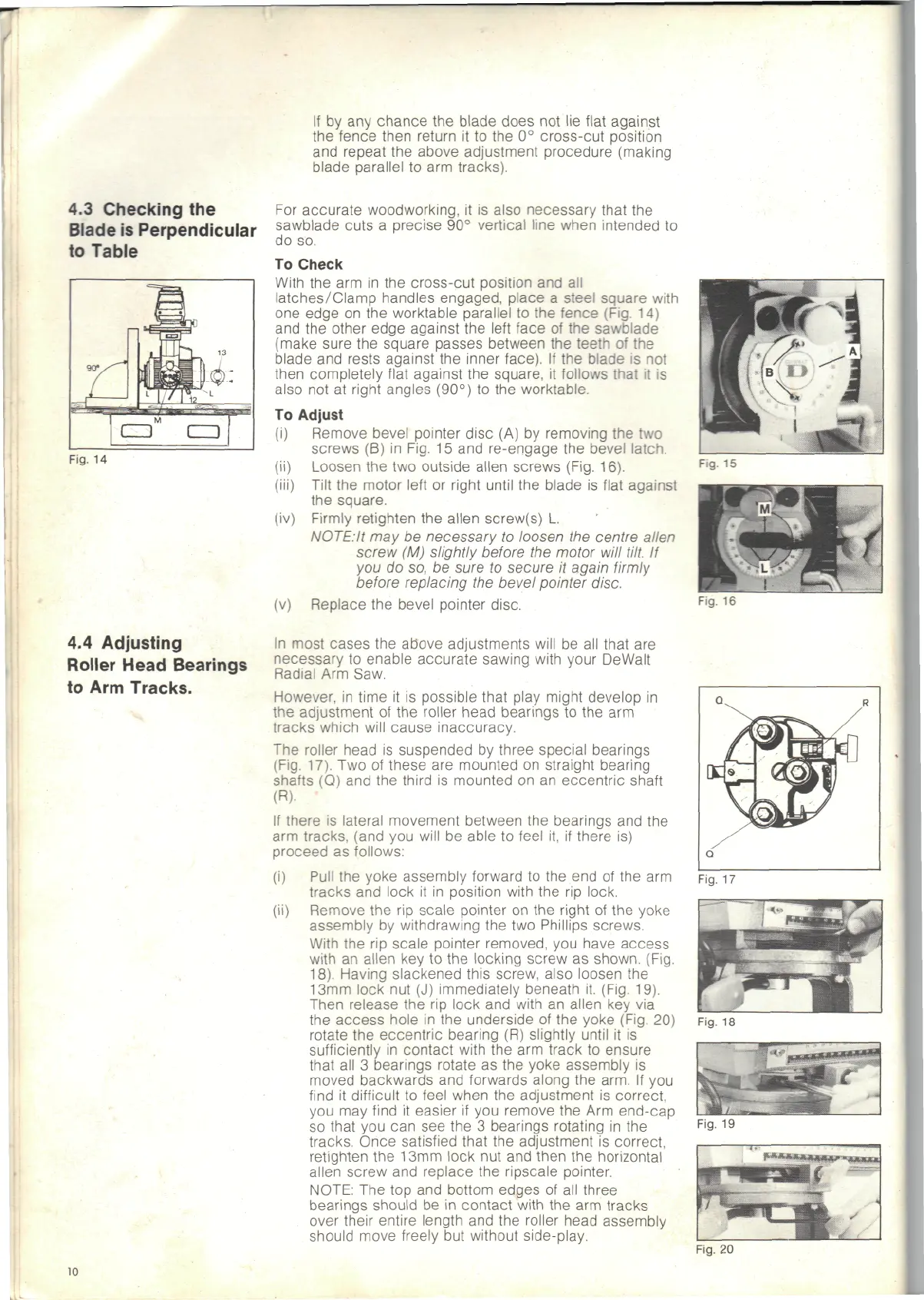

4.3

Checking

the

Blade

is

Perpendicular

to

Table

Fig.

14

4.4

Adjusting

Roller

Head

Bearings

to Arm

Tracks.

(iv)

For

accurate woodworking,

it is

also necessary that

the

sawblade cuts

a

precise

90°

vertical

line

when

intended

to

do so.

To

Check

With

the arm in the

cross-cut position

and all

latches/Clamp handles engaged, place

a

steel square with

one

edge

on the

worktable parallel

to the

fence (Fig.

14)

and the

other edge against

the

left

face

of the

sawblade

(make sure

the

square passes between

the

teeth

of the

blade

and

rests against

the

inner face).

If the

blade

is not

then completely flat against

the

square,

it

follows

that

it is

also

not at

right angles (90°)

to the

worktable.

To

Adjust

(i)

Remove bevel pointer disc

(A) by

removing

the two

screws

(B) in

Fig.

15

and

re-engage

the

bevel

latch.

Loosen

the two

outside

alien

screws

(Fig.

16).

Tilt

the

motor

left

or

right

until

the

blade

is

flat

against

the

square.

Firmly

retighten

the

alien

screw(s)

L.

NOTE:It

may be

necessary

to

loosen

the

centre

alien

screw

(M)

slightly before

the

motor

will

tilt.

If

you do so, be

sure

to

secure

it

again

firmly

before replacing

the

bevel pointer disc.

(v)

Replace

the

bevel pointer disc.

In

most cases

the

above adjustments will

be all

that

are

necessary

to

enable accurate

sawing

with

your

DeWalt

Radial

Arm

Saw.

However,

in

time

it is

possible that play might develop

in

the

adjustment

of the

roller

head

bearings

to the arm

tracks

which

will

cause inaccuracy.

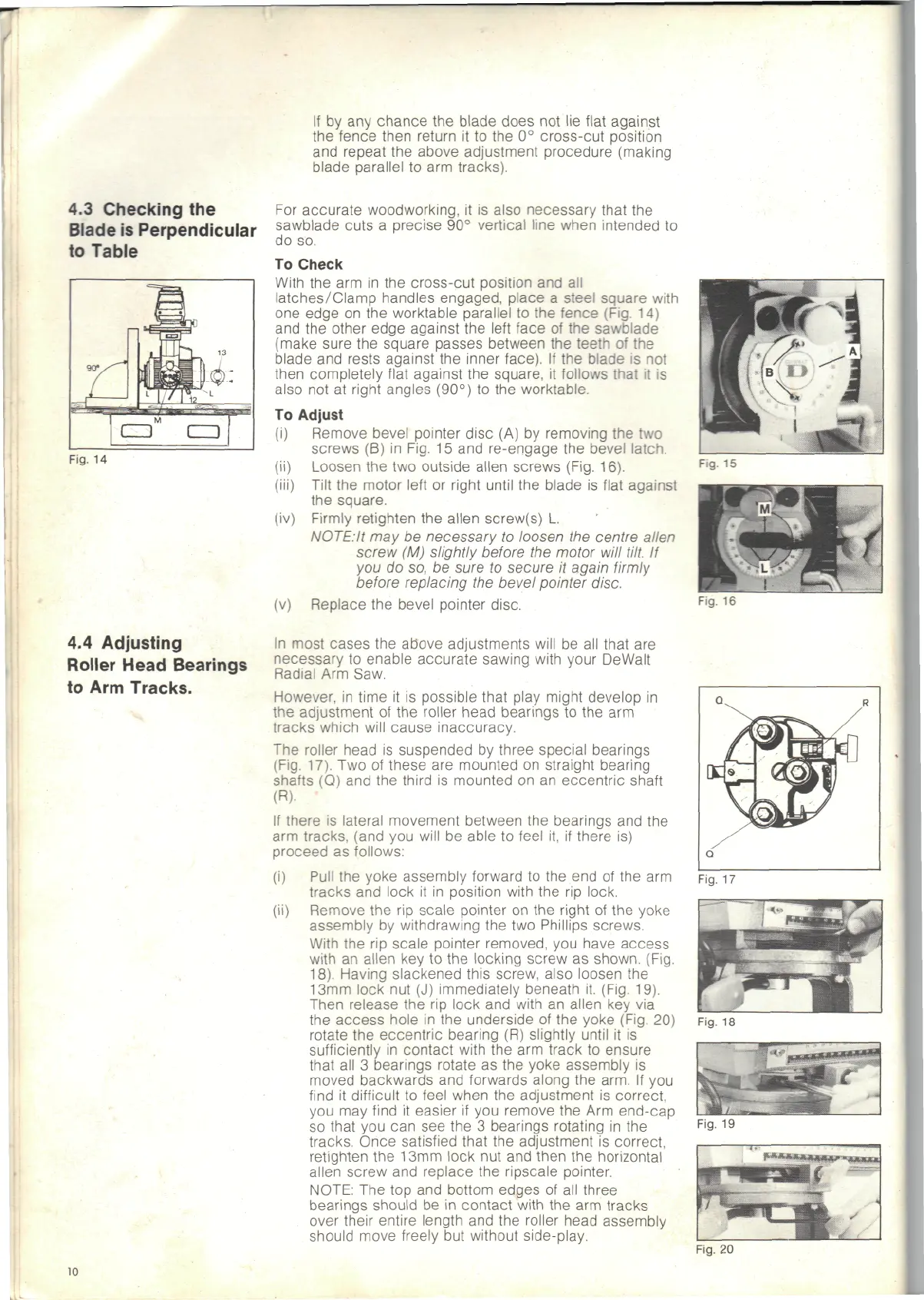

The

roller head

is

suspended

by

three special bearings

(Fig.

17).

Two of

these

are

mounted

on

straight bearing

shafts

(Q) and the

third

is

mounted

on an

eccentric shaft

(R).

If

there

is

lateral movement between

the

bearings

and the

arm

tracks, (and

you

will

be

able

to

feel

it, if

there

is)

proceed

as

follows:

(i)

Pull

the

yoke assembly forward

to the end of the arm

tracks

and

lock

it in

position with

the rip

lock.

(ii) Remove

the rip

scale

pointer

on the

right

of the

yoke

assembly

by

withdrawing

the two

Phillips screws.

With

the rip

scale pointer removed,

you

have access

with

an

alien

key to the

locking

screw

as

shown. (Fig.

18).

Having slackened this screw, also loosen

the

13mm

lock

nut (J)

immediately beneath

it.

(Fig. 19).

Then

release

the rip

lock

and

with

an

alien

key via

the

access hole

in the

underside

of the

yoke (Fig.

20)

rotate

the

eccentric bearing

(R)

slightly until

it is

sufficiently

in

contact with

the arm

track

to

ensure

that

all 3

bearings rotate

as the

yoke assembly

is

moved backwards

and

forwards along

the

arm.

If you

find

it

difficult

to

feel when

the

adjustment

is

correct,

you

may

find

it

easier

if you

remove

the Arm

end-cap

so

that

you can see the 3

bearings rotating

in the

tracks.

Once satisfied that

the

adjustment

is

correct,

retighten

the

13mm

lock

nut and

then

the

horizontal

alien screw

and

replace

the

ripscale pointer.

NOTE:

The top and

bottom edges

of all

three

bearings

should

be in

contact

with

the arm

tracks

over

their

entire length

and the

roller

head assembly

should move freely

but

without side-play.

Fig.

15

Fig.

16

Fig.

17

Fig.

18

Fig.

19

Fig.

20

10

Loading...

Loading...