6.

MAKING

A

TRIAL

CUT

. ;-•

Having

completed

the

above adjustment

procedure,

it is

now

time

to

make

a

straight cross-cut

in a

piece

of

timber.

Note:

If,

when

you

were

setting

up

your

machine,

the

saw

carriage

travel

was not as

smooth

as you

would

expect,

that

probably

means there

are

pieces

of

polystyrene

packing

stuck

either

to the

arm

tracks

or to the 3

bearings

on the

yoke

assembly.

With

a

clean,

dry

cloth

wipe

both

the

tracks

and the

bearings

to

eliminate

this.

6.1

Wiring

up to the

Mains

Single-Phase 240v Models

Connect

a

standard

13

amp

rubber-covered

earthed

plug

to

the

cable attached

to the

machine

as

shown

in the

illustration. Make sure that

the

cable

clamp

is

holding

the

outer sheath

of the

cable securely before fixing

the cap to

the

plug.

Plug

in and

switch

on at the

mains socket.

Three-Phase

415v

Models

Three-phase machines should

be

wired directly into

the

mains

by a

suitably qualified electrician.

6.2

Making

the Cut

(i)

With

the

mitre

lock

engaged,

lock

the arm

clamp

handle

so

that

the

sawblade

is

positioned

for a

straight

0°

cross- cut.

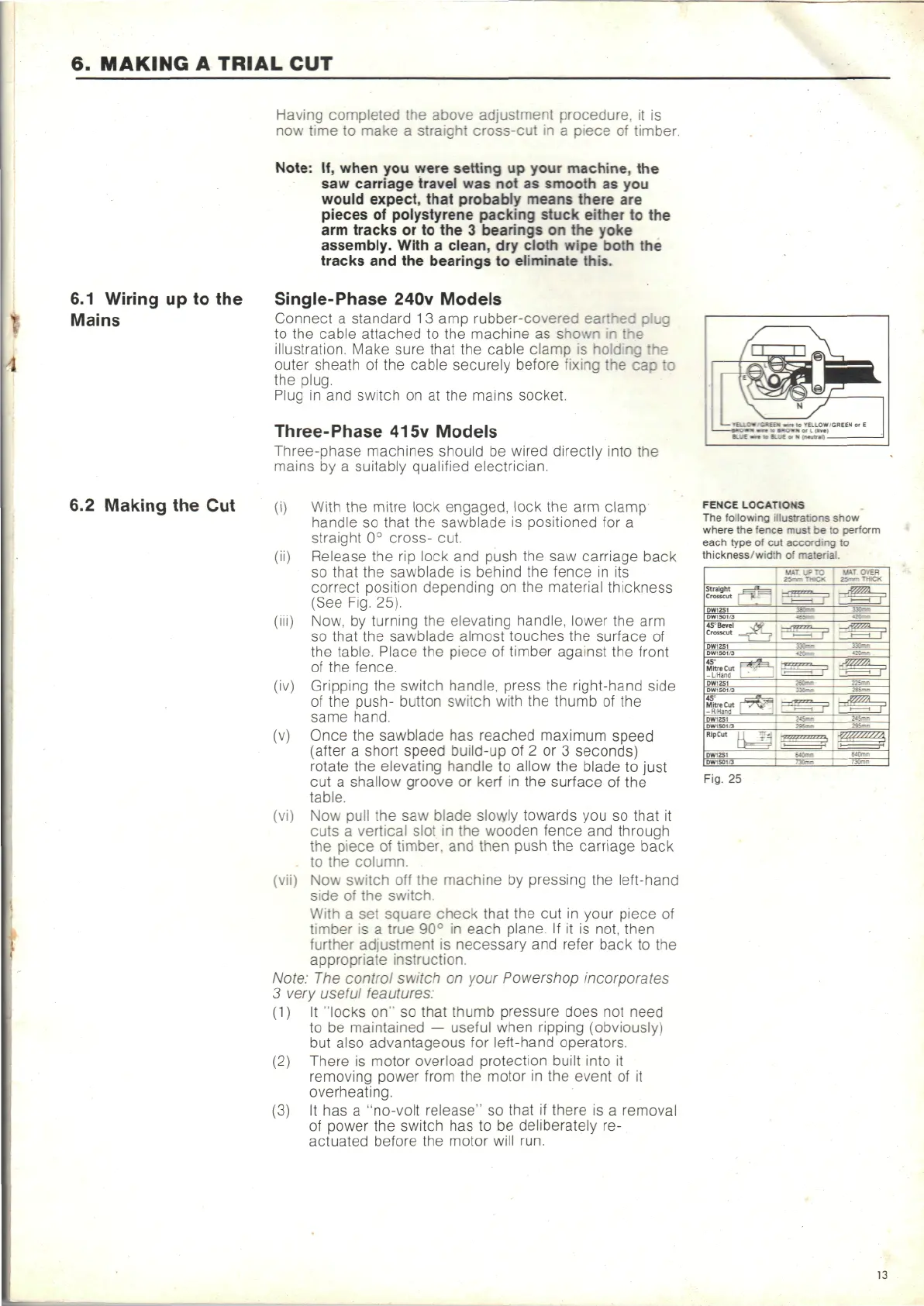

(ii)

Release

the rip

lock

and

push

the saw

carriage back

so

that

the

sawblade

is

behind

the

fence

in its

correct position depending

on the

material thickness

(See

Fig. 25).

(iii)

Now,

by

turning

the

elevating handle, lower

the arm

so

that

the

sawblade almost touches

the

surface

of

the

table. Place

the

piece

of

timber against

the

front

of

the

fence.

(iv)

Gripping

the

switch handle, press

the

right-hand side

of

the

push- button switch

with

the

thumb

of the

same hand.

(v)

Once

the

sawblade

has

reached

maximum speed

(after

a

short speed build-up

of 2 or 3

seconds)

rotate

the

elevating handle

to

allow

the

blade

to

just

cut a

shallow groove

or

kerf

in the

surface

of the

table.

(vi)

Now

pull

the saw

blade

slowly towards

you so

that

it

cuts

a

vertical slot

in the

wooden fence

and

through

the

piece

of

timber,

and

then

push

the

carriage

back

to

the

column.

(vii)

Now

switch

off the

machine

by

pressing

the

left-hand

side

of the

switch.

With

a set

square check that

the cut in

your piece

of

timber

is a

true

90° in

each plane.

If it is

not, then

further adjustment

is

necessary

and

refer

back

to the

appropriate instruction.

Note:

The

control

switch

on

your

Powershop

incorporates

3

very

useful

feautures:

(1)

It

"locks

on" so

that thumb pressure does

not

need

to

be

maintained

—

useful when ripping (obviously)

but

also advantageous

for

left-hand operators.

(2)

There

is

motor overload protection built into

it

removing power from

the

motor

in the

event

of it

overheating.

(3)

It has a

"no-volt release"

so

that

if

there

is a

removal

of

power

the

switch

has to be

deliberately

re-

actuated before

the

motor

will

run.

FENCE

LOCATIONS

The

following

illustrations

show

where

the

fence must

be to

perform

each

type

of cut

according

to

thickness/width

of

material.

V--

: .

~

25*

T

v-

THICK

45

Mitre

LHai

45

Mitre

ut

-R Hi

Fig.

25

13

Loading...

Loading...