12.7 Routing

Fig.

61

Fig.

62

J

\

Fig.

65

•J

\

^-

J

Fig.

66

The

mounting

of one of the

optional Router Brackets,

enabling

you to fit a

portable Router

to

your

Powershop,

broadens

the

scope

enormously

for

accurate,

decorative

woodworking

with your machine.

There

is a

choice

of two

mounting brackets:-

One is

suitable

for the

Black

&

Decker

DN66

Woodworker

or

any

other

with

a.043mm

collar.

The

other

will

enable

most

ELU

Routers (MOF 96/31

/98/77)

to be

secured

to

your

Powershop.

Since

the

Router itself

will

be

operating

and not the

Powershop

motor,

you can

disconnect

the

Powershop

completely

from

the

power supply.

The

mounting procedure

is as

follows:-

(i)

Remove

the

blade guard, blade

and all

flanges from

the

motor shaft.

(ii) Position

the

router bracket over

the end of the

Powershop motor

shaft,

carefully locating

the

lugs

of

the

bracket

behind

the

lugs

on the end of the

machine's motor housing (Fig. 59).

In

lining these

up

correctly,

the

hole

in the

upper

arm of the

bracket

will

also locate over

the

standard guard retaining

bolt

on

the top of the

motor housing, where

it can be

firmly

secured with

the

wing

nut

supplied,

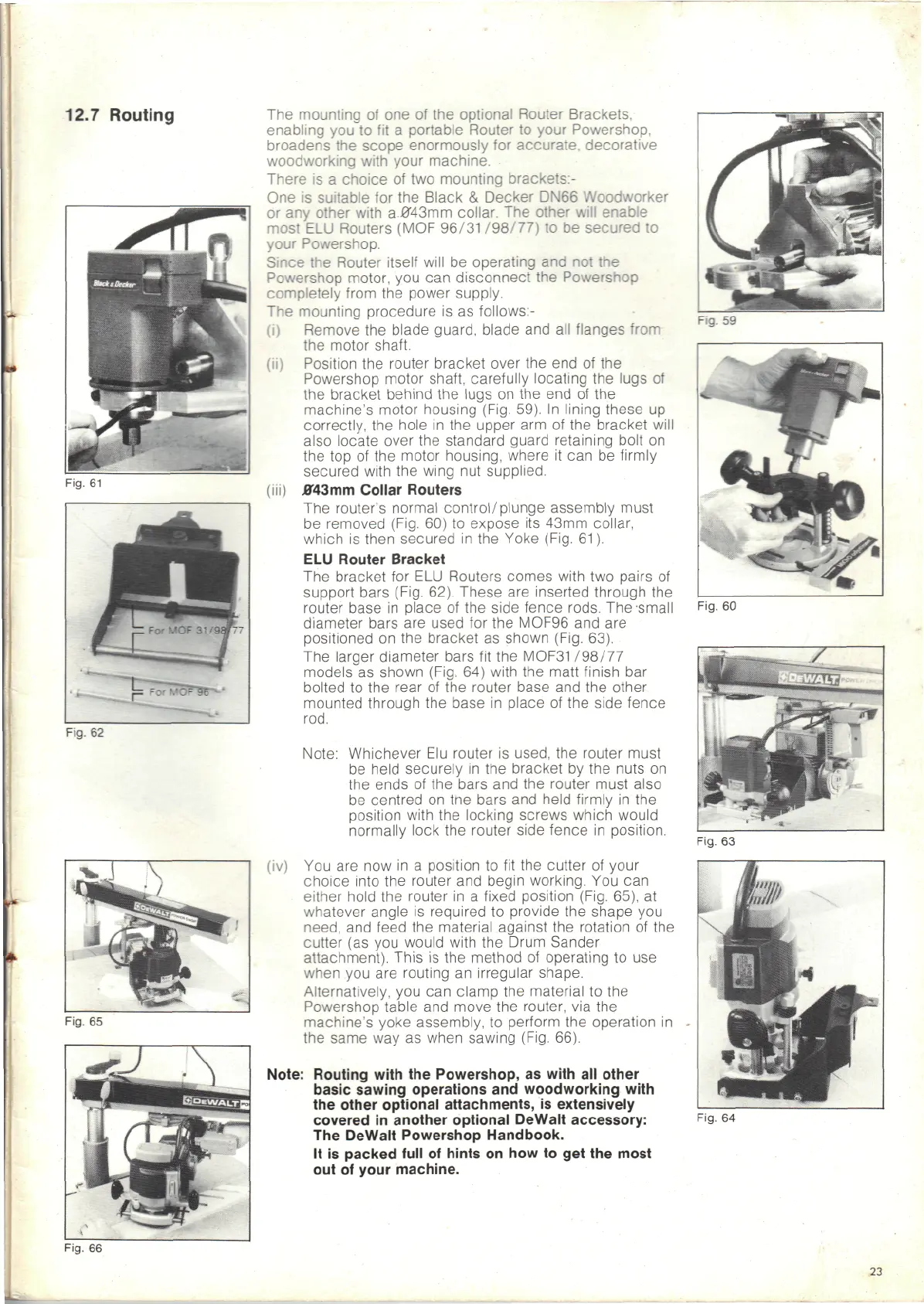

(iii)

j043mm

Collar Routers

The

router's

normal

control/plunge

assembly

must

be

removed (Fig.

60) to

expose

its

43mm collar,

which

is

then secured

in the

Yoke (Fig.

61).

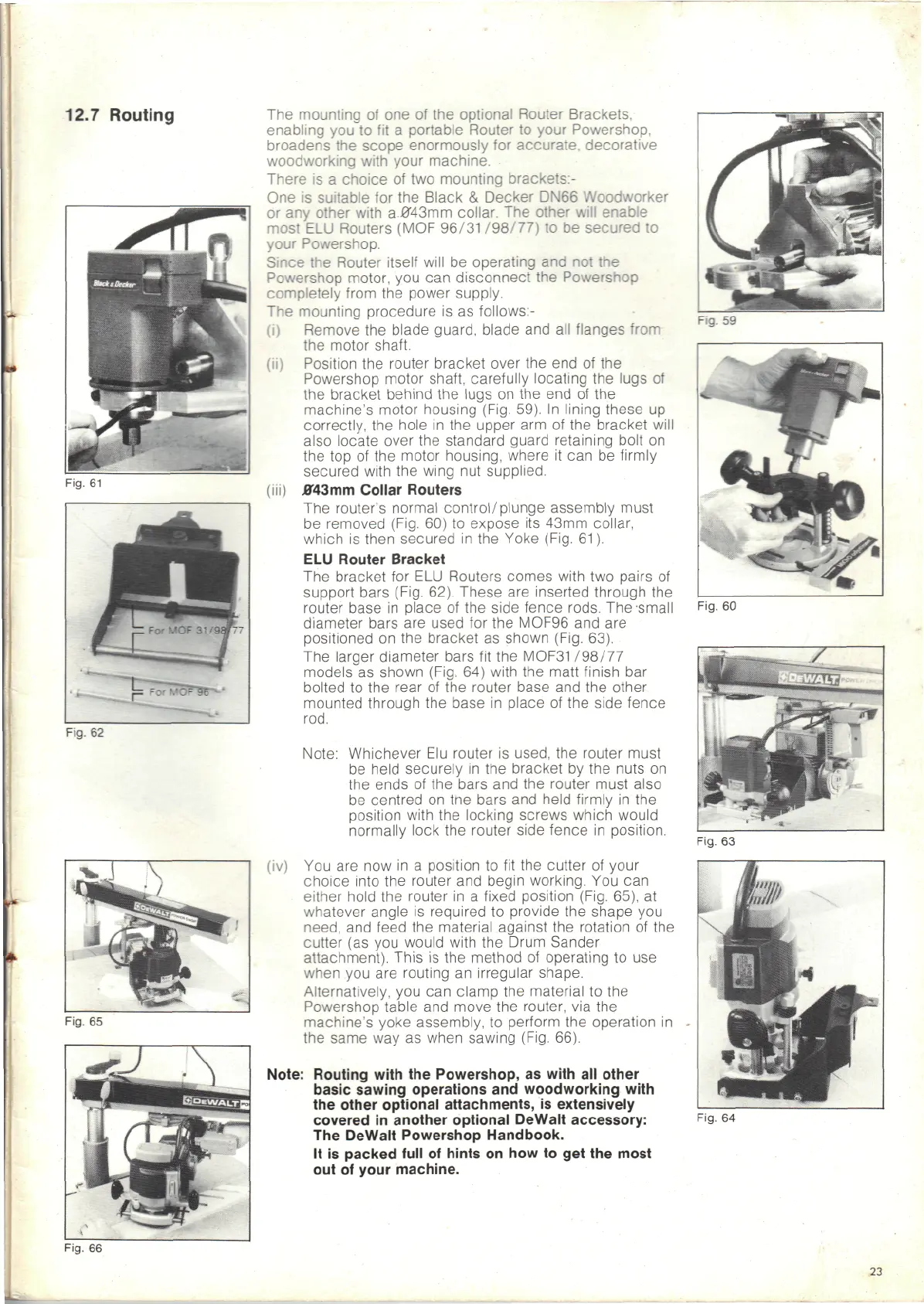

ELU

Router Bracket

The

bracket

for ELU

Routers comes with

two

pairs

of

support

bars (Fig. 62). These

are

inserted through

the

router

base

in

place

of the

side fence rods.

The-small

diameter bars

are

used

for the

MOF96

and are

positioned

on the

bracket

as

shown (Fig. 63).

The

larger diameter bars

fit the

MOF31

/98/77

models

as

shown (Fig.

64)

with

the

matt finish

bar

bolted

to the

rear

of the

router base

and the

other

mounted through

the

base

in

place

of the

side fence

rod.

Note: Whichever

Elu

router

is

used,

the

router must

be

held securely

in the

bracket

by the

nuts

on

the

ends

of the

bars

and the

router must also

be

centred

on tne

bars

and

held firmly

in the

position with

the

locking screws which would

normally

lock

the

router side fence

in

position.

(iv)

You are now in a

position

to fit the

cutter

of

your

choice into

the

router

and

begin working.

You can

either hold

the

router

in a

fixed position (Fig. 65),

at

whatever

angle

is

required

to

provide

the

shape

you

need,

and

feed

the

material against

the

rotation

of the

cutter

(as you

would with

the

Drum Sander

attachment). This

is the

method

of

operating

to use

when

you are

routing

an

irregular shape.

Alternatively,

you can

clamp

the

material

to the

Powershop table

and

move

the

router,

via the

machine's yoke assembly,

to

perform

the

operation

in

the

same

way as

when sawing (Fig. 66).

Note: Routing with

the

Powershop,

as

with

all

other

basic sawing operations

and

woodworking with

the

other optional attachments,

is

extensively

covered

in

another optional DeWalt accessory:

The

DeWalt Powershop Handbook.

It

is

packed full

of

hints

on how to get the

most

out of

your machine.

Fig.

60

Fig.

63

Fig.

64

23

Loading...

Loading...