8.

CLAMP HANDLE ADJUSTMENTS

(i)

The

Mitre

Clamp

handle

(18)

may

need

to be

adjusted

if its

secure position means

it

hinders

use of

the

elvating handle.

In

such

a

case,

simply

slacken

the

clamp handle

and

push

it

into

the

casting

so

that

the nut on the

other

end

protrudes from

its

surrounding

casting.

You can

then tighten

up the nut

half

a

turn

and

pull

the

clamp handle back

out so

that

when

it is

again

retightened

it

does

not

obstruct

the

elevating

handle.

(ii)

The

Bevel

Clamp

handle (12)

may be

adjusted

in

the.

same

way as in (i)

above

but you may

find

it

easier

to do so

with

the

motor

in its

vertical position.

(iii)

The

adjustment

of the

yoke clamp

is a

little

more

involved.

If

you

find

that

the

Yoke Clamp

has

insufficient

movement

to

satisfactorily

clamp

the

yoke securely,

adjust

as

follows:

(a)

Remove

the arm

end-cap.

(b)

Remove

the

complete yoke assembly

from

the arm

tracks.

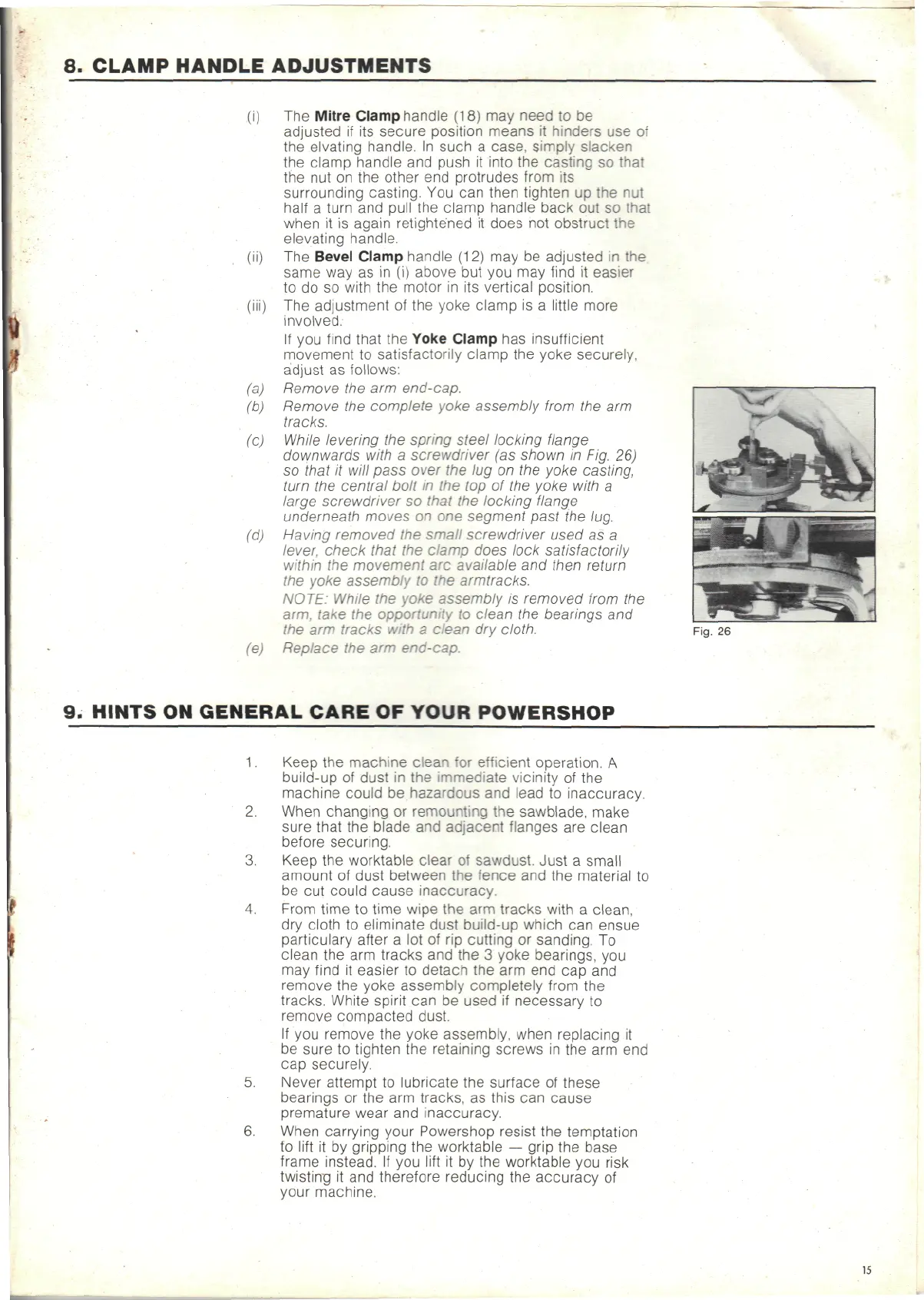

(c)

While

levering

the

spring steel locking flange

downwards with

a

screwdriver

(as

shown

in

Fig.

26)

so

that

it

will

pass over

the lug on the

yoke casting,

turn

the

central bolt

in the top of the

yoke with

a

large

screwdriver

so

that

the

locking flange

underneath moves

on one

segment past

the

lug.

(d)

Having removed

the

small screwdriver used

as a

lever,

check that

the

clamp does lock satisfactorily

within

the

movement

arc

available

and

then return

the

yoke assembly

to the

armtracks.

NOTE:

While

the

yoke assembly

is

removed

from

the

arm, take

the

opportunity

to

clean

the

bearings

and

the arm

tracks with

a

clean

dry

cloth.

(e)

Replace

the arm

end-cap.

Fig.

26

9.

HINTS

ON

GENERAL CARE

OF

YOUR POWERSHOP

1.

Keep

the

machine

clean

for

efficient operation.

A

build-up

of

dust

in the

immediate vicinity

of the

machine could

be

hazardous

and

lead

to

inaccuracy.

2.

When

changing

or

remounting

the

sawblade, make

sure

that

the

blade

and

adjacent flanges

are

clean

before

securing.

3.

Keep

the

worktable clear

of

sawdust. Just

a

small

amount

of

dust between

the

fence

and the

material

to

be

cut

could cause inaccuracy.

4.

From time

to

time wipe

the arm

tracks with

a

clean,

dry

cloth

to

eliminate dust build-up which

can

ensue

particulary

after

a lot of rip

cutting

or

sanding.

To

clean

the arm

tracks

and the 3

yoke bearings,

you

may

find

it

easier

to

detach

the arm end cap and

remove

the

yoke assembly completely from

the

tracks.

White

spirit

can be

used

if

necessary

to

remove

compacted dust.

If

you

remove

the

yoke assembly, when replacing

it

be

sure

to

tighten

the

retaining screws

in the arm end

cap

securely.

5.

Never attempt

to

lubricate

the

surface

of

these

bearings

or the arm

tracks,

as

this

can

cause

premature

wear

and

inaccuracy.

6.

When carrying your Powershop resist

the

temptation

to

lift

it by

gripping

the

worktable

—

grip

the

base

frame instead.

If you

lift

it by the

worktable

you

risk

twisting

it and

therefore

reducing

the

accuracy

of

your

machine.

15

Loading...

Loading...