12.3

Ploughing/

Grooving

'

Flat

grourf«U>acUr>read

V-

Premium

ado

Head

Fig.

47

12.4 Disc Sanding

Note:

In

this upright position, however,

it is

essential

that

the

Dado

Head

is

covered

by the

standard

sawblade guard (with

the

riving knife assembly

removed)

and

no/the

Shaping

Head guard.

With

repeated passes,

the

ordinary

saw

blade

will

often

cut

grooves adequately. When

a

wider groove

is

needed

a

Dado Head

is

more appropriate (Fig. 46).

It is

also ideal

for

cutting rebates

and

housings, making

a

wide deep

cut in

one

pass.

Set

at an

angle

the

Dado Head

can be

used

to

make

the

grooves

for

staircases (mitre

position),

long grooves

and

rebates

(rip

position),

and

mortices

or

tenons

(blade

horizontal).

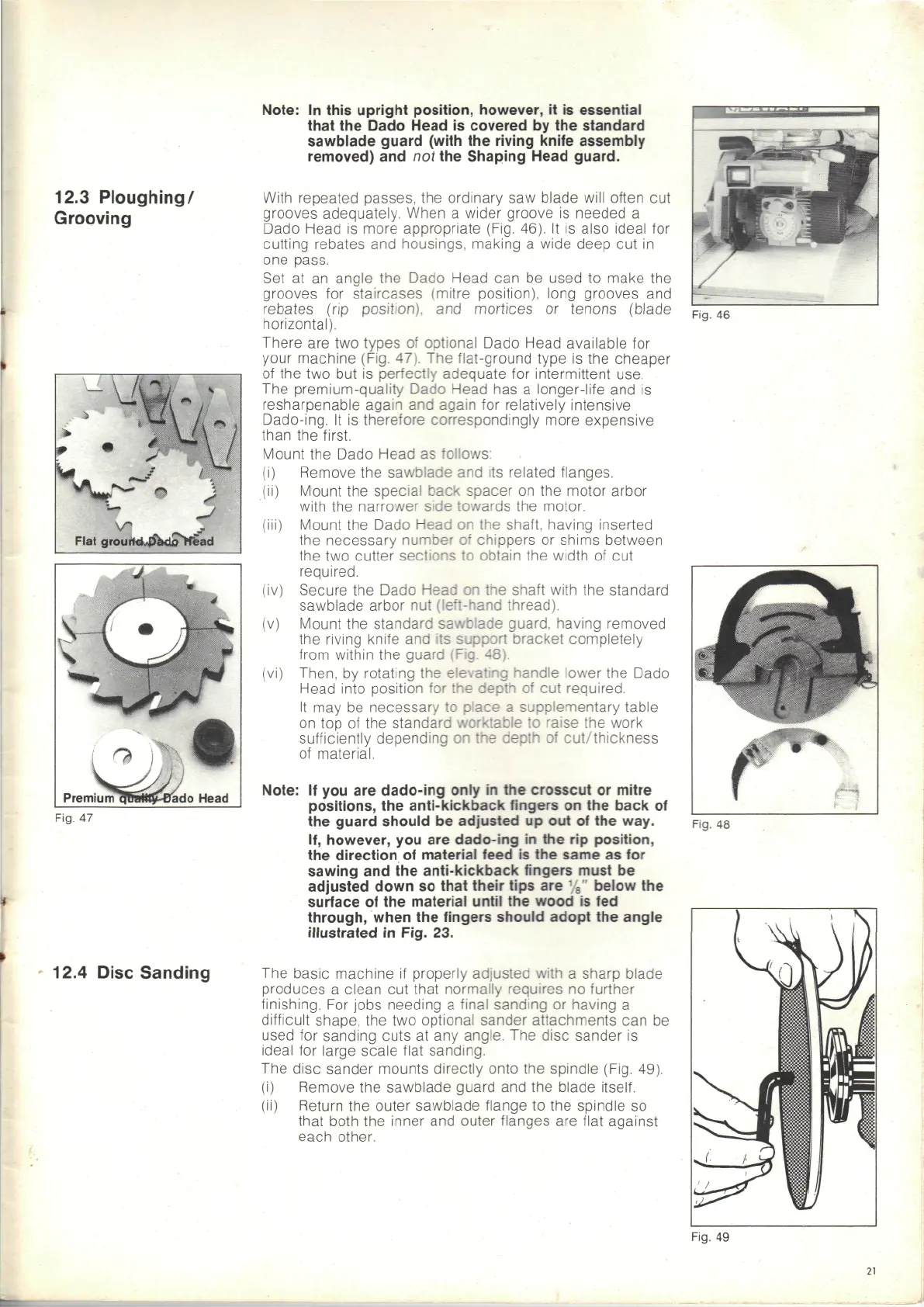

There

are two

types

of

optional

Dado

Head available

for

your

machine (Fig. 47).

The

flat-ground type

is the

cheaper

of

the two but is

perfectly adequate

for

intermittent use.

The

premium-quality

Dado

Head

has a

longer-life

and is

resharpenable again

and

again

for

relatively intensive

Dado-ing.

It is

therefore correspondingly more expensive

than

the

first.

Mount

the

Dado Head

as

follows:

(i)

Remove

the

sawblade

and its

related flanges.

(ii)

Mount

the

special

back

spacer

on the

motor arbor

with

the

narrower

side

towards

the

motor,

(iii)

Mount

the

Dado

Head

on the

shaft, having inserted

the

necessary

number

of

chippers

or

shims between

the

two

cutter

sections

to

obtain

the

width

of cut

required.

(iv)

Secure

the

Dado

Head

on the

shaft with

the

standard

sawblade arbor

nut

(left-hand

thread).

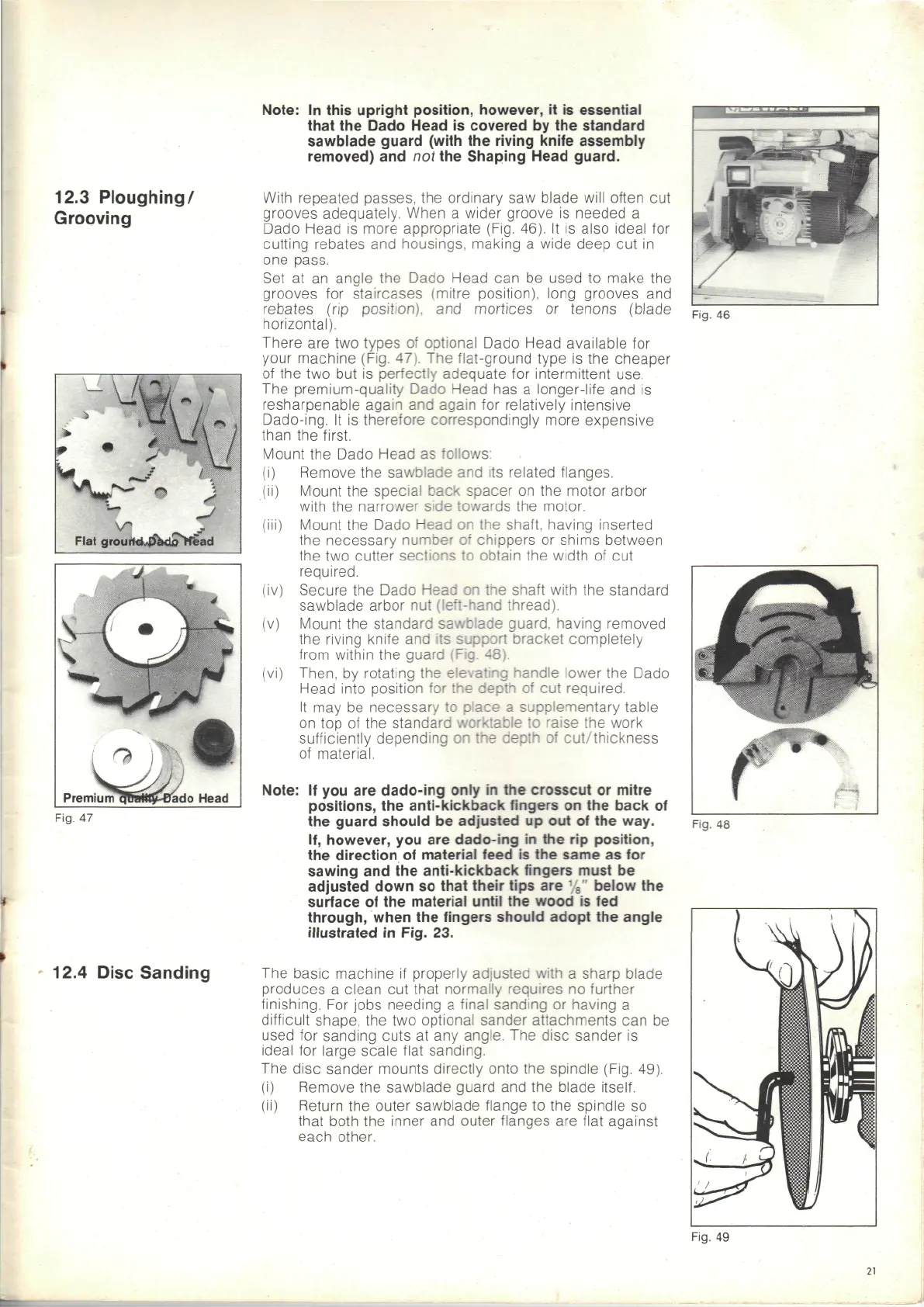

(v)

Mount

the

standard

sawblade

guard, having removed

the

riving

knife

and its

support

bracket completely

from

within

the

guard (Fig. 48).

(vi)

Then,

by

rotating

the

elevating

handle

lower

the

Dado

Head into position

for the

depth

of cut

required.

It

may be

necessary

to

place

a

supplementary table

on

top of the

standard

worktable

to

raise

the

work

sufficiently

depending

on the

depth

of

cut/thickness

of

material.

Note:

If you are

dado-ing

only

in the

crosscut

or

mitre

positions,

the

anti-kickback

fingers

on the

back

of

the

guard

should

be

adjusted

up out of the

way.

If,

however,

you are

dado-ing

in the rip

position,

the

direction

of

material

feed

is the

same

as for

sawing

and the

anti-kickback

fingers

must

be

adjusted

down

so

that

their

tips

are

"

e

"

below

the

surface

of the

material

until

the

wood

is fed

through,

when

the

fingers

should

adopt

the

angle

illustrated

in

Fig.

23.

The

basic machine

if

properly adjusted with

a

sharp blade

produces

a

clean

cut

that normally requires

no

further

finishing.

For

jobs needing

a

final sanding

or

having

a

difficult

shape,

the two

optional sander attachments

can be

used

for

sanding cuts

at any

angle.

The

disc sander

is

ideal

for

large scale flat sanding.

The

disc sander mounts directly onto

the

spindle (Fig. 49).

(i)

Remove

the

sawblade guard

and the

blade

itself,

(ii)

Return

the

outer sawblade flange

to the

spindle

so

that

both

the

inner

and

outer flanges

are

flat

against

each

other.

Fig.

46

Fig.

48

Fig.

49

21

Loading...

Loading...