ENGLISH

10

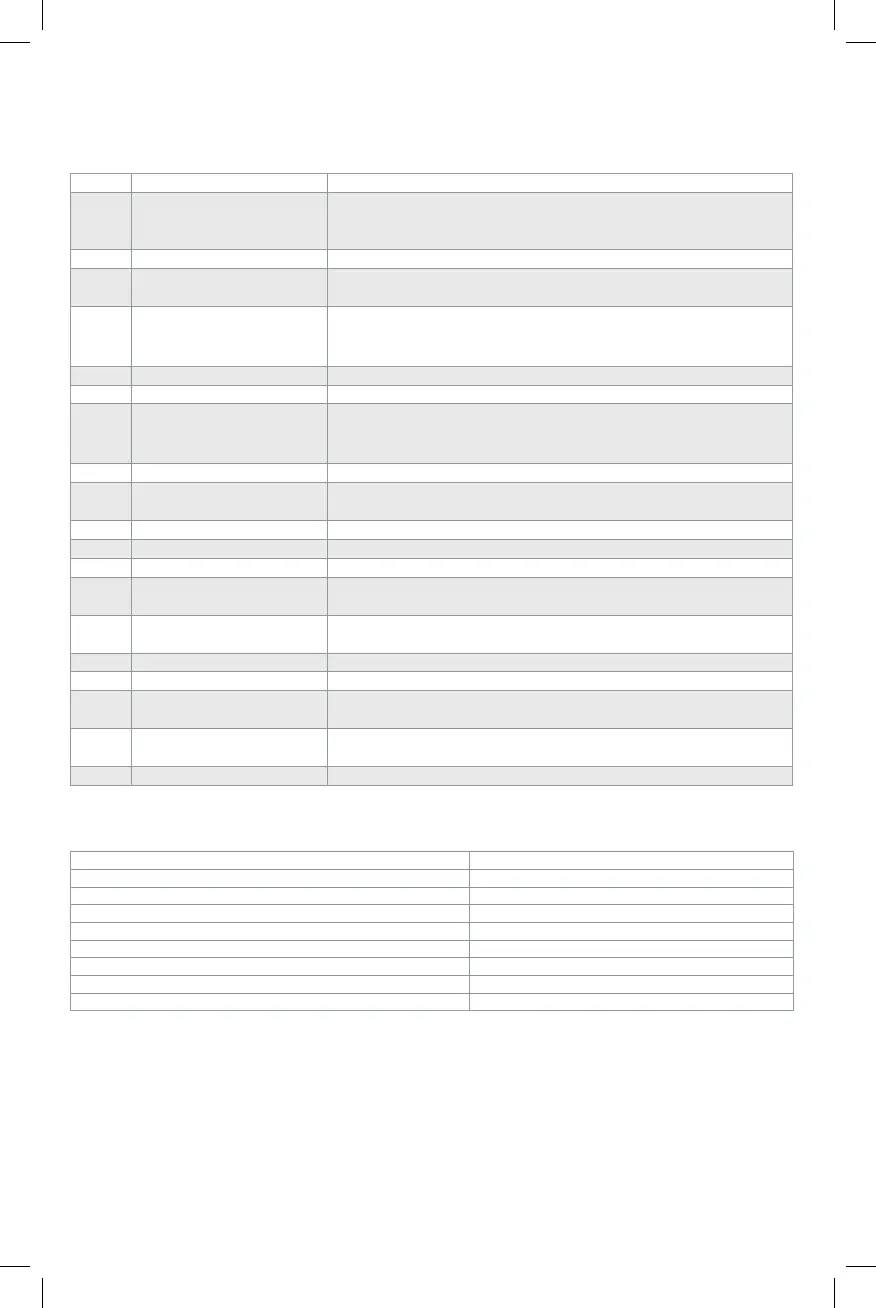

Troubleshooting Guide

This section provides a list of the more frequently encountered malfunctions, their causes and corrective actions. The

operator or maintenance personnel can perform some corrective actions, and others may require the assistance of a

qualified

technician or yourdealer.

Code Possible Cause Possible Solution

1

Pressure switch does not shut off

motor when compressor reaches

cut-out pressure.

Set the Auto On/Off switch to "Off" and unplug unit, if the unit does not shut off contact a D

WALT

factory service center or a D

WALT authorized service center.

2 Pressure switch cut-out too high. Contact a D

WALT factory service center or a D

WALT authorized service center.

3

Tube fittings are not tight enough. Tighten fittings where air can be heard escaping. Check fittings with soapy water solution. Do

Not Overtighten.

4

Defective air tank. Air tank must be replaced. Do not repair the leak.

WARNING: Risk of bursting. Do not drill into, weld or otherwise modify air tank or it will

weaken. The air tank can rupture or explode.

5 Leaking seals. Contact a D

WALT factory service center or a D

WALT authorized service center.

6 Defective safety valve. Operate safety valve manually by pulling on ring. If valve still leaks, it must be replaced.

7

Regulator is not adjusted correctly for

accessory being used.

It is normal for some pressure drop to occur when an accessory is used, adjust the regulator as

instructed in One-turn Regulator under Description of Operation if pressure drop is excessive.

NOTE: Adjust the regulated pressure under flow conditions while accessory is being used.

8 Prolonged excessive use of air. Decrease amount of air usage.

9

Compressor is not large enough

for accessory.

Check the accessory air requirement. If it is higher than the CFM or pressure supplied by your air

compressor, a larger compressor is needed to operate accessory.

11 Check valve restricted. Contact a D

WALT factory service center or a D

WALT authorized service center.

12 Air leaks. Tighten fittings.

13 Regulator is damaged. Replace.

14

Motor overload protection switch

has tripped.

Refer to Motor Overload Protector under Description of Operation. If motor overload protection

trips frequently, contact a D

WALT factory service center or a D

WALT authorized service center.

15

Tank pressure exceeds pressure switch

cut-in pressure.

Motor will start automatically when tank pressure drops below cut-in pressure of pressure switch.

16 Loose electrical connections. Contact a D

WALT factory service center or a D

WALT authorized service center.

17 Possible defective motor. Contact a D

WALT factory service center or a D

WALT authorized service center.

18

Paint spray on internal motor parts. Contact a D

WALT factory service center or a D

WALT authorized service center. Do not operate the

compressor in the paint spray area. Refer to DANGER: RISK OF EXPLOSION OR FIRE.

19

Pump does not run because tank

pressure is above cut-in pressure.

Drain tank to below cut-in pressure when pump turns on.

20 Pump does not run due to safety fault. Cycle On/Off Switch from "Off" to "On."

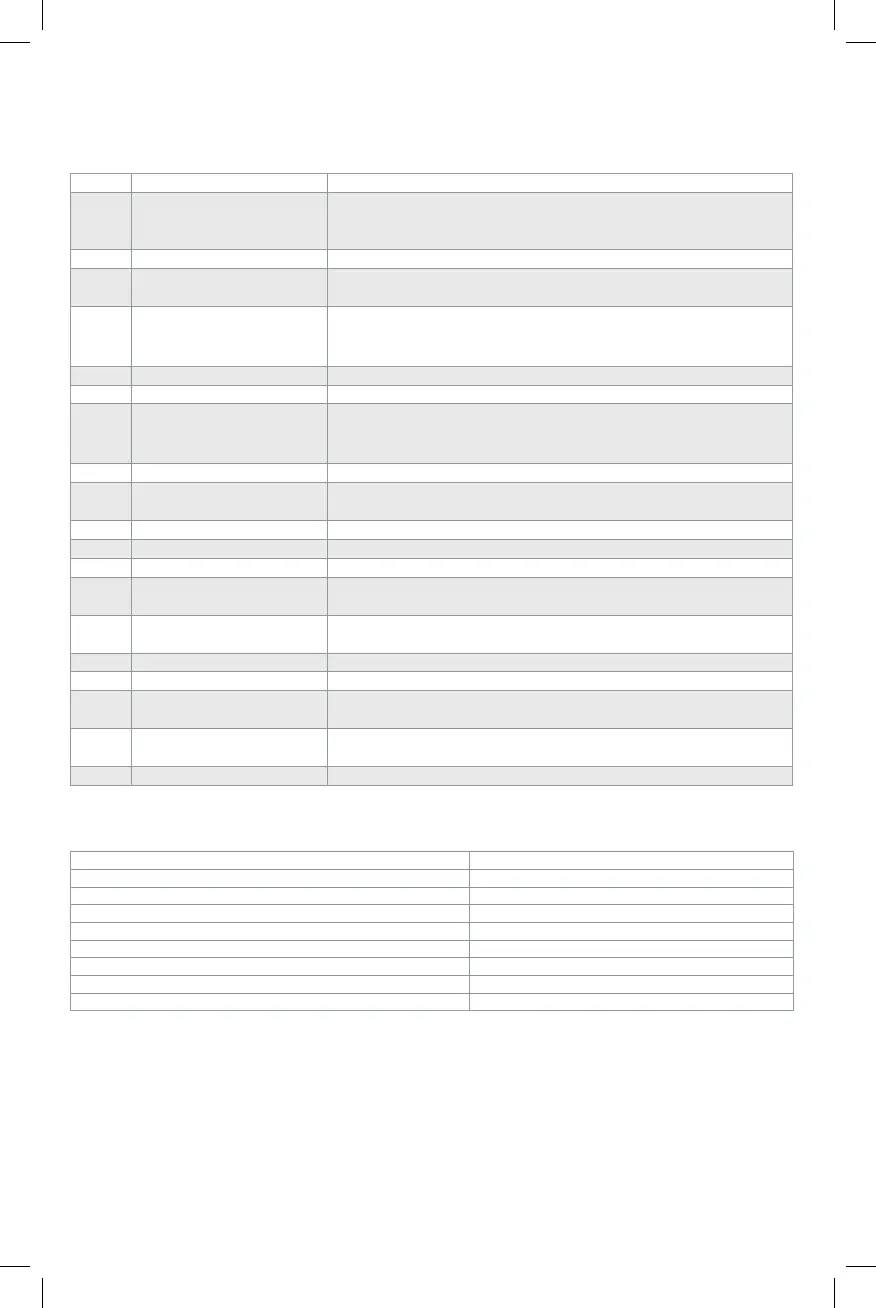

Troubleshooting Codes

Problem Code

Excessive air tank pressure-safety valve pops off 1, 2

Air leaks 3

Air leaks in air tank or at air tank welds 4

Air leaks between head and valve plate 5

Air leaks from safety valve 6

Compressor is not supplying enough air to operate accessories 7, 8, 9, 10, 11, 12

Regulator knob has continuous air leak 13

Regulator will not shut off air outlet 13

Motor will not run 6, 14, 15, 16, 17, 18, 19, 20

Loading...

Loading...