12

ENGLISH

To Check Safety Valve (Fig.A, C)

WARNING: Risk of Bursting. If the safety valve

does not work properly, over‑pressurization

may occur, causing air tank rupture or

anexplosion.

WARNING: Risk from Flying Objects. Always wear

certified eye protection with sideshields.

The safety valve

4

has been set for the highest permitted

pressure of the pressure vessel. It is prohibited to adjust the

safety valve. Actuate the safety valve

4

from time to time to

ensure that it works when required.

1. Loosen the safety valve nut until you can hear the

compressed air being released.

2. Then fully tighten the safety valve nut.

3. Always keep the safety valve

4

and surrounding area clean

and free of obstutructions.

NOTE: If the safety valve

4

is stuck or does not operate

smoothly, contact a DeWALT servicecentre.

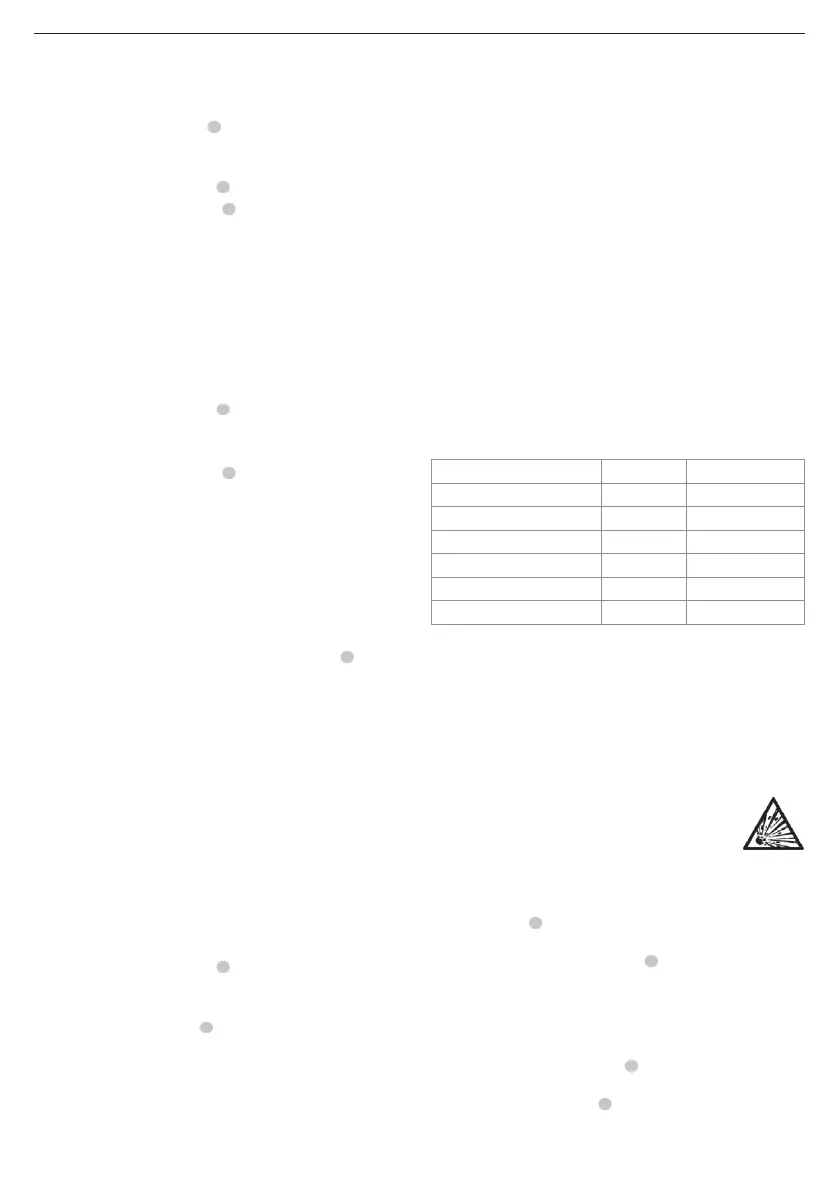

Customer Responsibilities

Before each use Daily or after each use

Check Safety Valve X

Drain Tank X

Check for air leaks X

Check for unusual noise/vibration X

Check hose and tool connection X

Adjustment of pressure control X

WARNING: Risk of unsafe operation. Unit cycles

automatically when power is on. When performing

maintenance, you may be exposed to voltage sources,

compressed air, or moving parts. Personal injuries can occur.

Before performing any maintenance, disconnect power source

from the compressor and bleed off all airpressure.

NOTE: Refer to the Operation section for the location ofcontrols.

MAINTENANCE

Your power tool has been designed to operate over a long

period of time with a minimum of maintenance. Continuous

satisfactory operation depends upon proper tool care and

regularcleaning.

WARNING: To reduce the risk of serious personal

injury, turn tool off and disconnect battery pack

before making any adjustments or removing/

installing attachments or accessories. An accidental

start‑up can causeinjury.

The charger and battery pack are notserviceable.

How to Use Your Unit (Fig.A, C)

How to Stop

WARNING: When loosening the hose coupling from the

quick‑connect coupler

9

, the coupling piece of the hose

must be held by hand in order to avoid injuries caused by

the recoilinghose.

1. Set the Auto On/Off switch

1

to"Off".

2. Turn the One-Turn regulator

6

anti-clockwise to set the

outlet pressure tozero.

3. Remove hose andtool/accessories.

4. Remove battery when not in use.

Before Starting

WARNING: Do not operate this unit until you read

this instruction manual for safety, operation and

maintenanceinstructions.

Before Each Start‑Up

1. Set the Auto On/Off switch

1

to"Off".

2. Remove battery. (Refer toInstalling and Removing the

Battery Pack from the Tool

3. Turn the One-Turn regulator

6

counterclockwise to set the

outlet pressure to zero.

4. Attach hose andtool/accessories.

WARNING: Risk of unsafe operation. Firmly grasp

air hose in hand when installing or disconnecting to

prevent hosewhip.

WARNING: Risk of unsafe operation. Do not use

damaged or wornaccessories.

NOTE: The hose or accessory will require a quick connect plug if

the air outlet is equipped with a quick connect body

9

.

WARNING: Risk of Bursting. Too much air pressure

causes a hazardous risk of bursting. Check the

manufacturer’s maximum pressure rating for air tools

and accessories. The regulator outlet pressure must never

exceed the maximum pressurerating.

NOTICE: Risk of property damage. Compressed air

from the unit may contain wa ter condensation and oil

mist. Do not spray un fil tered air at an item that could be

damaged by moisture. Some air tools and accessories may

require filtered air. Read the in struc tions for the air tools

andaccessories.

How to Start

1. Install the battery into thecompressor.

2. Attach hose andtool/accessories.

3. Set the Auto On/Off switch

1

to "Auto On" and allow

tank pressure to build. Motor will stop when tank pressure

reaches "cut-out"pressure.

4. Turn One-Turn regulator

6

clockwise to increase pressure

and stop when desired pressure isreached.

NOTE: Make sure that the desired pressure is not more

than the maximum pressure of the connected hose or the

connectedtool.

WARNING: Risk of unsafe operation. If any unusual

noise or vibration is noticed, stop the compressor

immediately and have it checked by a trained

servicetechnician.

WARNING: Ensure the regulator is set to a pressure lower

than the maximum operating pressure of thetool.

The compressor is ready foruse.

Loading...

Loading...