16.4. Understanding Factors that Determine Carbon

Monoxide Levels

The primary factors that ultimately determine the expected level of Car-

bon Monoxide in a space where a propane machine is operating are as

follows:

• Room air volume

• Air Exchange Rate (ventilation rate)

• Carbon Monoxide Production Rate

Room air volume can be determined by multiplying the length, width, and

height of a room, and then reducing for any material in the room.

For example: A room that is 100 ft x 100 ft with a 10 ft ceiling has a volume

of: 100 x 100 x 10 = 100,000 cubic feet, when empty. If the room consists

of 80% open air, and 20% material, the total room air volume = 100,000 *

80% = 80,000 cubic feet.

Air Exchange Rate is a measure of the room’s ventilation. Air exchange

rate is typically measured in terms of the qty of air changes per hour

(ACPH). In other words, the Air Exchange Rate when expressed as

ACPH, measures the frequency (per hour) that the room’s air is replaced

by fresh air. The higher the ACPH, the more frequently air is being ventilat-

ed, for example:

In a room with ACPH = 6, the room’s air would be completely extracted

and replaced by fresh air 6 times every hour, or once every 10 minutes.

Here are some air exchange rates, expressed in ACPH, that would be

expected in dierent types of industrial and commercial spaces:

Carbon Monoxide Production Rate is, itself, the result of several factors:

• The total ow of engine exhaust, which is determined by the relative

amount of engine load of application

• The amount of Carbon Monoxide present in the exhaust, expressed as PPM

• The quantity of propane engines in operation

A 603cc propane engine under normal operating conditions (50% of max-

imum load) will produce total exhaust at a rate of 13 CFM (cubic feet per

minute), with Carbon Monoxide making up 50 PPM of the total exhaust.

Therefore, the CO production rate (in CFM) is calculated as follows:

Qty of Engines * Exhaust Flow per Engine (CFM) * CO Level of Exhaust

(PPM)

Calculating the CO production rate of one 603cc engine operating under

normal conditions is as follows:

1 engine * 13 cubic ft / min per engine * 50 / 1,000,000 = 0.00065 cubic

feet/min

Knowing all of these factors, we can calculate the equilibrium carbon

monoxide level of a room (in PPM) as follows:

Total CO production rate (in cubic feet / min) * Air Exchange Rate

(expressed in minutes) *1,000,000 Room air volume (in cubic feet)

Basement Parking

Residential Basement

Bedroom

Residential Bathroom

Residential Living Rooms

Residential Kitchen

Residential Laundry

Business Oces

Business Lunch Break Rooms

Business Conference Rooms

Business Copy Rooms

Computer Rooms

Restaurant Dining Area

Restaurant Food Staging Area

Restaurant Bar

Public Hallway

Public Retail Store

Public Foyer

Church

Public Auditorium

Commercial kitchens & Restrooms

Smoking rooms

Laboratories

Classrooms

Warehousing

15–30

3–4

5-6

6-7

6-8

7-8

8-9

6-8

7-8

8-12

10-12

10-14

8-10

10-12

15-20

6-8

6-10

8-10

8-12

12-14

15–30

15-20

6–12

3–4

3-10

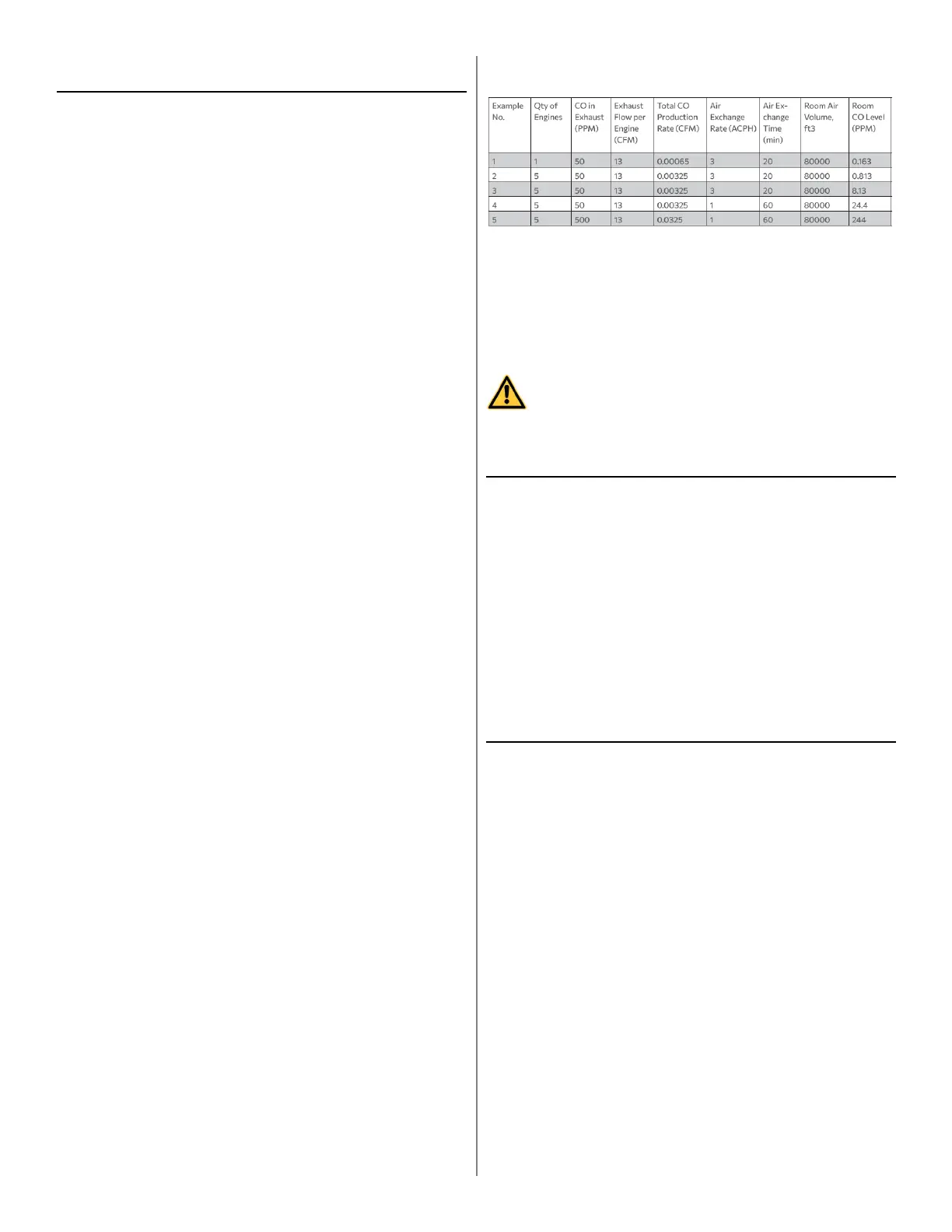

This table shows the calculated equilibrium carbon monoxide level under

dierent examples with varying inputs:

There are several important notes to take away from these calculations:

• More engines running in a space leads to higher room CO level. This is

shown comparing Examples No. 1 & 2.

• Smaller room size leads to higher room CO level. This is shown compar-

ing Examples No. 2 & 3.

• Lower ventilation (Air Exchange Rate) leads to higher room CO level.

This is shown comparing Examples No. 3 & 4.

• Higher CO level in the exhaust leads to higher room CO level. This is

shown comparing Examples No. 4 & 5.

DANGER: Operating this machine or any propane powered

engine in a space with NO ventilation (a sealed space), is guar-

anteed to result in dangerously high level of CO, that will cause

serious injury or death to the operator and bystanders. Never

operate the machine in a sealed space with no ventilation.

Reviewing the above section, we already know that to reduce CO expo-

sure the following action should be taken:

• Limit the quantity of engines running in a space.

• Insure adequate ventilation. Higher ventilation rates (higher air exchange

rate) will always result in lower CO exposure.

• Insure proper maintenance and performance of engine to avoid high CO

content in engine exhaust.

• All of these tips are especially important to follow when using the ma-

chine in small spaces.

This section oers additional considerations and best practices to reducing

Carbon Monoxide exposure:

• Air Exchange and CO Diusion

• Application Considerations

• Examples of CO Management in Spaces

• Maintenance of Equipment

The most reliable method to prevent CO Poisoning is to ensure all the CO

produced is vented outside. With wood stoves or gas heaters this is per-

formed with ductwork that carries the exhaust and CO outside. Non-sta-

tionary combustion type equipment must be used in such a way that CO

is not allowed to rise to a harmful or dangerous level. CO does not readily

dissipate or mix with air on its own. Air currents can “stir” the CO and dilute

the concentration or ppm values by mixing it with the available air. When

using equipment over a large area in a short time “stirring” occurs as you

walk, or to say it another way, your Eective Operating Zone is large.

When activity is concentrated to a smaller area as in a stripping applica-

tion, the Eective Operating Zone is small, and “stirring” must be forced by

the use of fans to increase the Eective Operating Zone and reduce high

concentrations of CO. “Air” exchange rates (air exchange is dened as

the exhausting of internal air to the external atmosphere), the size of the

Eective Operating Zone, amount of CO produced, level of human activity,

and the duration of exposure are all factors in the determination of the

production of carboxyhemoglobin and the amount of CO blood saturation.

16.5. Methods to Reduce Carbon Monoxide Exposure

16.6. Air Exchange and CO Diusion

Loading...

Loading...