8. TROUBLESHOOTING

Note: When troubleshooting, always rst check for simple causes which may at rst seem too obvious. For example, an engine unable to start may be

caused by an empty propane cylinder or an unopened service valve.

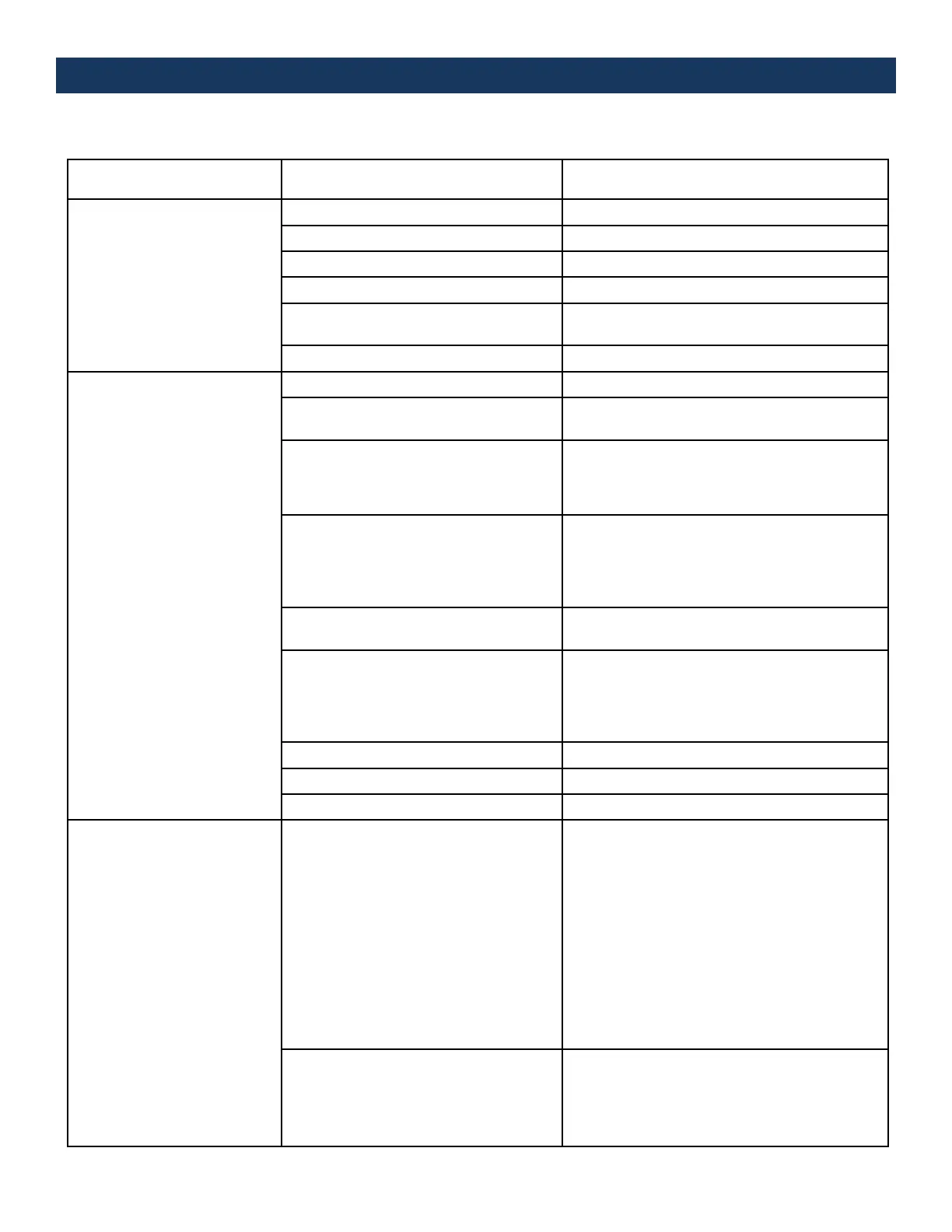

SYMPTOM POSSIBLE CAUSE CORRECTIVE ACTION

Engine does not turn over.

Weak or dead battery.

Recharge or replace battery.

Battery cable is disconnected.

Connect battery cable at connector.

Ignition switch faulty.

Check switch, replace if necessary.

Faulty Starter.

Check starter, replace if necessary.

Damaged or disconnected wire in

wiring harness.

Check wiring harness to identify faulty con-

nection, replace or reconnect as required.

Numerous other causes.

See engine manual or dealer.

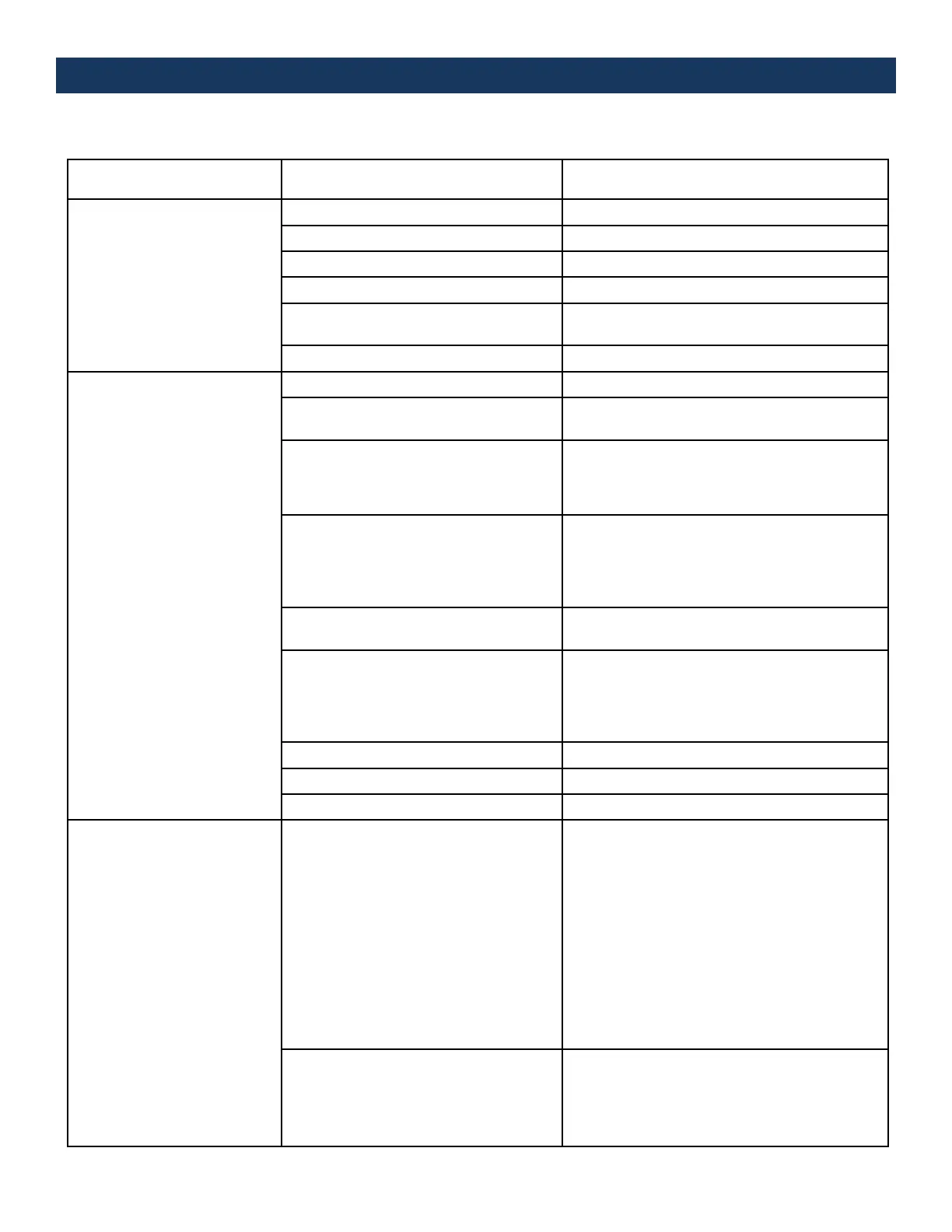

Engine turns over, but does

not start or run.

Propane cylinder is empty.

Rell cylinder or replace with full cylinder.

Main fuel service valve on propane

cylinder is closed.

Manually open main fuel service valve on

propane cylinder.

REGO tting (fuel hose to cylinder

connector) is not fully seated.

Manually close main fuel service valve. Dis-

connect REGO tting. Reconnect and hand

tighten to ensure secure connector is fully

seated. Slowly open main fuel service valve.

Propane cylinder OPD (overow pro-

tection device) has been triggered

Manually close main fuel service valve. Dis-

connect REGO tting. Wait 5 seconds. Re-

connect and hand tighten to ensure secure

connector is fully seated.

Slowly open main fuel service valve.

Propane regulator out of adjustment or

faulty.

Have certied dealer inspect regulator and

adjust or replace.

Poor quality propane causes deposits

of particles in regulator or valves.

Have certied dealer inspect regulator and

clean or replace. Service engine valves

according to engine manual instructions.

Contact propane supplier to provide clean

HD5 propane.

Spark plug not ring.

Replace spark plug.

Faulty oil pressure switch.

Check or replace oil pressure switch.

Numerous other causes.

See engine manual or dealer.

Propane regulator freezes

and prevents ow of

propane.

Liquid propane is entering

regulator.

• Ensure cylinder is designed for VAPOR

withdrawal.

• Ensure cylinder is designed for the correct

orientation (horizontal or vertical).

• Ensure cylinder is installed in correct ori-

entation. Make sure locator pin is inserted

into positioning slot on cylinder collar, and

follow orientation arrow indications/labels on

cylinder.

• Ensure propane cylinder is not overlled.

• Ensure use of application does not allow

operating angles to exceed equipment OEM

instructions.

Low ambient temperature.

It is normal condition for propane regulator

to operate at colder temperature than ambi-

ent, which may cause condensation or frost

formation depending on ambient

temperature and humidity levels.

Loading...

Loading...