DA435HA: 99901219: 2-319980930

2-4. DRIVELINE INSTALLATION

TECHNIQUES

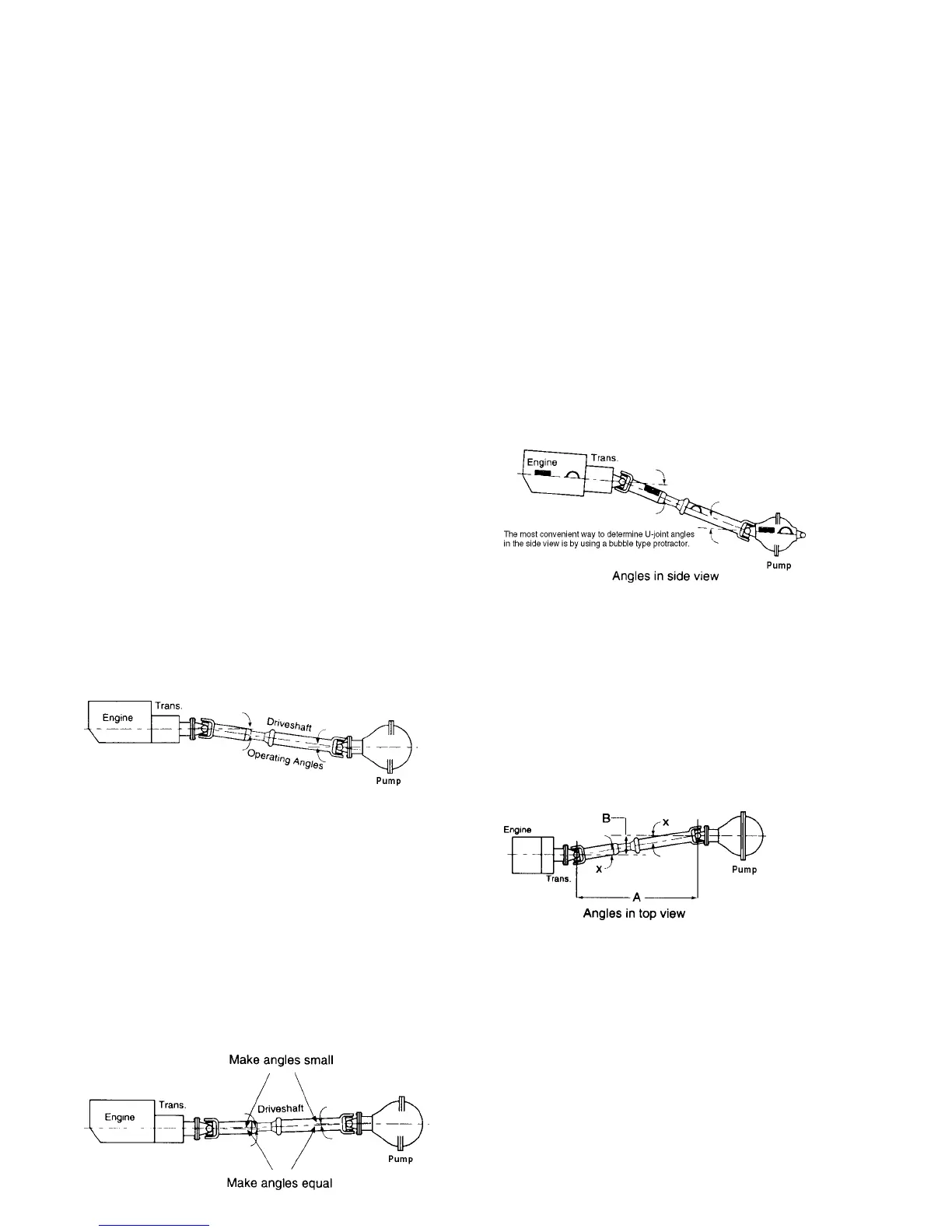

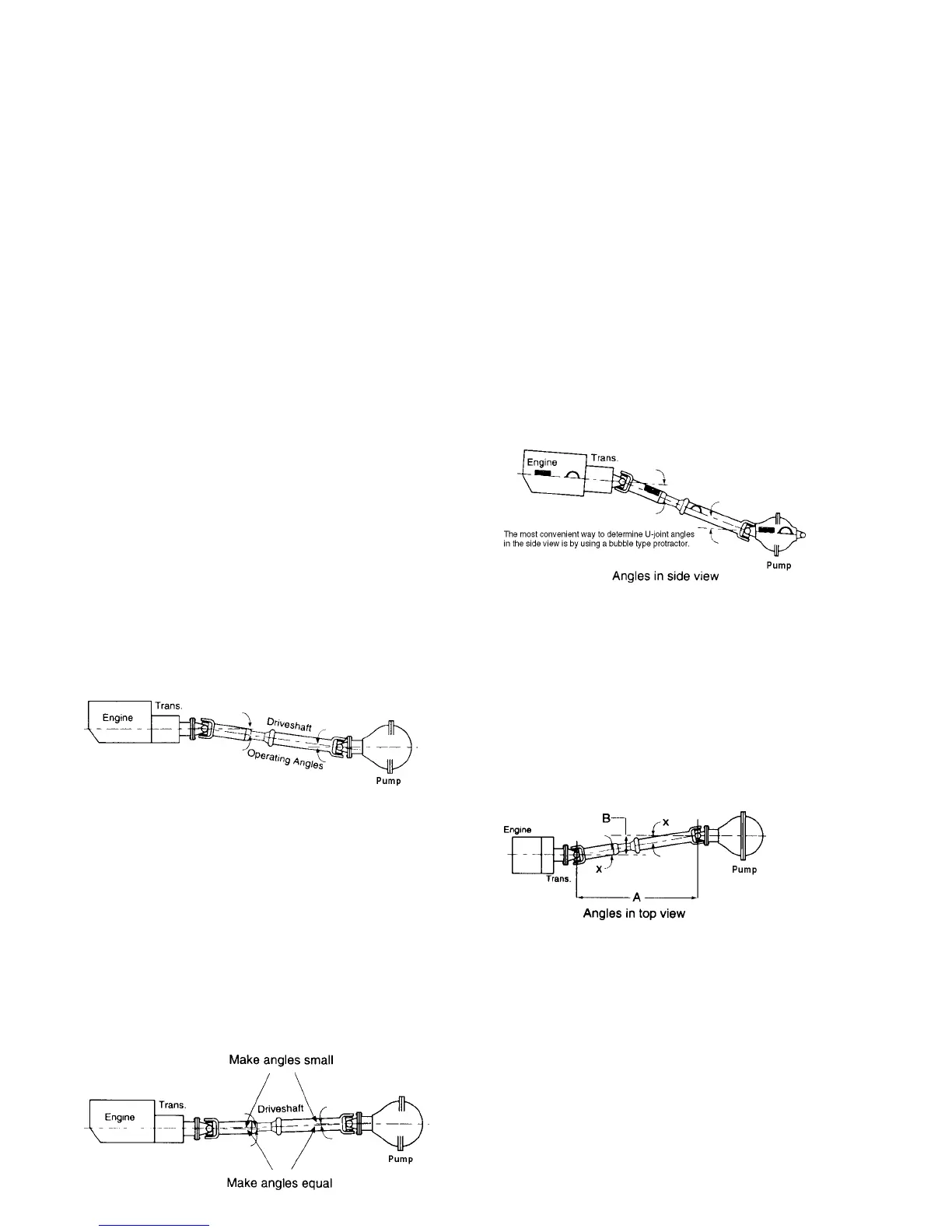

2-4-1. U-JOINT OPERATING ANGLES

Every U-joint that operates at an angle creates

vibration.

U-joint operating angles are probably the most

common cause for driveline vibration in vehicles

that have been reworked or that have had auxiliary

equipment installed.

When reworking a chassis or installing a new

driveshaft in a vehicle, make sure that you follow

the basic rules that apply to u-joint operating angles,

as follows:

1. U-joint operating angles at each end of a shaft should

always be at least 1°.

2. U-joint operating angles on each end of a driveshaft

should always be equal within 1° of each other.

3. U-joint operating angles should not be larger than 3°. If

more than 3°, make sure they do not exceed the

maximum recommended angles for the RPM at which

they will be operating.

A u-joint operating angle is the angle that occurs at each

end of a driveshaft when the output shaft of the

transmission and the input shaft of the pump are not in

line. See figure.

The connecting driveshaft operates with an angle at

each u-joint. It is that angle that creates a vibration.

REDUCING AND CANCELING VIBRATION

A key point to remember about u-joint operating

angles: To reduce the amount of vibration, the

angles on each end of a driveshaft should always be

SMALL.

To cancel an angle vibration, the u-joint operating

angles need to be EQUAL within 1° at each end of a

shaft. See figure.

2-4-2. SINGLE PLANE AND COMPOUND

U-JOINT OPERATING ANGLES

There are two types of u-joint operating angles,

single plane and compound.

SINGLE PLANE

Single plane angles occur when the transmission and

pump components are in line when viewed from

either the top or side, but not both.

Determine the u-joint operating angle in an

application where the components are in line when

viewed from the top, but not in line when viewed

from the side, is as simple as measuring the slope of

the components in the side view, and adding or

subtracting those slopes to determine the angle. See

figure.

These angles should be SMALL and equal within 1°.

Determine the u-joint operating angles on a shaft

that is straight when viewed from the side and offset

when viewed from the top requires the use of a

special chart (See accompanying chart). In this type

of application, the centerlines of the connected

components must be parallel when viewed from the

top, as shown. These angles should also be SMALL

and equal within 1°. See figure.

Look at the angle chart and note that the smaller the

offset, the smaller the resultant angle.

To reduce the possibility of vibration, keep any

offset between connected points to a minimum.

Loading...

Loading...