LonWorks Communication Bus Fundamentals

Network Guide 63

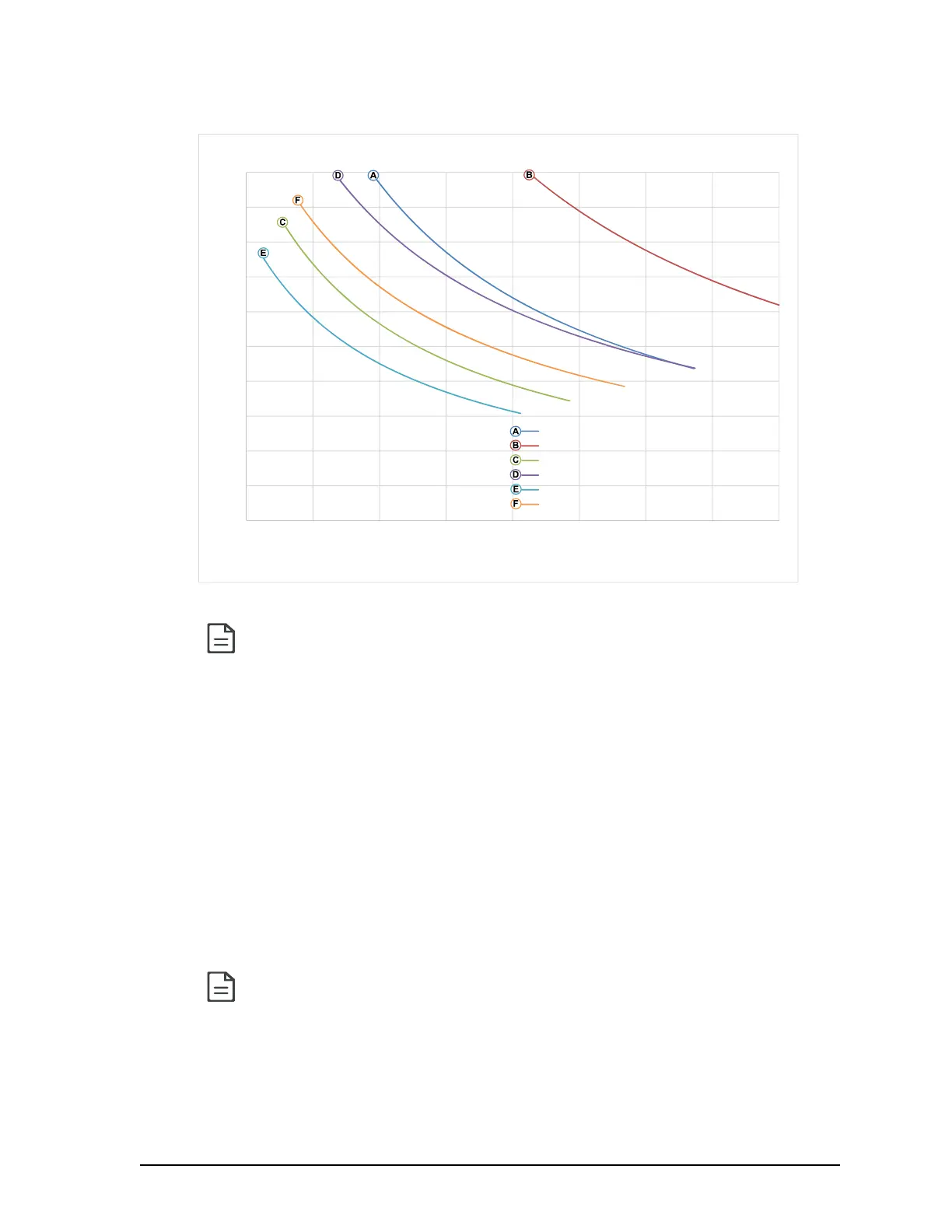

Figure 37: Maximum Number of VAVS Devices on a Daisy-Chain at Evenly Spaced Intervals

For non-VAV devices, determine the appropriate size transformer for the job as follows:

• Add up the power requirements of all devices plus all external loads (see About External

Loads on page 61). Multiply the total power needed by a multiplier of 1.3, as a security

margin. For example, to power five devices (15 VA each), the total load is 75 VA multiplied

by 1.3 is 98 VA. Choose a size of transformer just over this amount: For example, a 100

VA model.

• When the total load of a number of devices requires a transformer with a rating greater

than 100 VA, use two or more transformers. Ensure that the load to be connected to each

transformer follows the guideline of Step 1 above.

Laboratory testing conditions for the above graph are as follows:

• Distance between each VAV is evenly spaced along the entire wire length

• Transformer specification: 100VA (120/24VAC)

• Tested at room temperature with low voltage line conditions: 108VAC (50Hz)

Always use a separate transformer for each ECL-600 series controller and for each

of its associated I/O Extension Modules. One terminal on the secondary side of each

of these transformers must be connected to the building's ground and to the respec-

tive controller's or I/O Extension Modules' 24V COM terminal. See ECx-4XX I/O

Extension Module Power Supply Requirements on page 66.

0

1

2

3

4

5

6

7

8

9

10

100150200250300350400450500

MaxVAVSinDaisy‐Chain

TotalWireLength

DaisyChainPerformance

VAVS + SmartVue (AWG18)

VAVS + SmartVue (AWG16)

VAVS + SmartVue + 2DO (1,6VA each) (AWG18)

VAVS + SmartVue + 2DO (1,6VA each) (AWG16)

VAVS + SmartVue + SmartVue CO2 + 2DO (1,6VA each) (AWG18)

VAVS + SmartVue + SmartVue CO2 + 2DO (1,6VA each) (AWG16)

(30) (45) (60) (75) (90) (105) (120) (135) (150)

Feet

(meters)

Loading...

Loading...