dIXEL

Installing and Operating Instructions

1592026000

1592026000 XW20K GB R1.0 22.02.2008.doc XW20K 4/5

fins in the coldest place, where most ice is formed, far from heaters or from the warmest place during

defrost, to prevent premature defrost termination.

10. TTL/RS485 Serial line

The TTL connector allows, by means of the external module TTL/RS485 (XJ485CX), to connect the

unit to a network line ModBUS-RTU compatible as the dIXEL monitoring system XJ500 (Version

3.0). The same TTL connector is used to upload and download the parameter list of the “HOT KEY“.

The instruments can be ordered wit the serial output RS485(Optional).

11. Use of the programming “HOT KEY “

The Wing units can UPLOAD or DOWNLOAD the parameter list from its own E2 internal memory to

the “Hot Key” and vice-versa.

11.1 DOWNLOAD (FROM THE “HOT KEY” TO THE INSTRUMENT)

1. Turn OFF the instrument by means of the ON/OFF key, remove the TTL serial cable if present,

insert the “Hot Key” and then turn the Wing ON.

2. Automatically the parameter list of the “Hot Key” is downloaded into the Wing memory, the

“DoL” message is blinking. After 10 seconds the instrument will restart working with the new

parameters.

3. Turn OFF the instrument remove the “Hot Key”, plug in the TTL serial cable, then turn it ON

again.

At the end of the data transfer phase the instrument displays the following messages:

“end “ for right programming.

The instrument starts regularly with the new programming.

“err” for failed programming.

In this case turn the unit off and then on if you want to restart the download again or remove

the “Hot key” to abort the operation.

11.2 UPLOAD (FROM THE INSTRUMENT TO THE “HOT KEY”)

1. Turn OFF the instrument by means of the ON/OFF key and remove the TTL serial cable if

present; then turn it ON again.

2. When the Wing unit is ON, insert the “Hot key” and push

o key; the "uPL" message

appears.

3. Push “SET” key to start the UPLOAD; the “uPL” message is blinking.

4. Turn OFF the instrument remove the “Hot Key”, plug in the TTL serial cable, then turn it ON

again.

At the end of the data transfer phase the instrument displays the following messages:

“end “ for right programming.

“err” for failed programming. In this case push “SET” key if you want to restart the

programming again or remove the not programmed “Hot key”.

12. ALARM SIGNALS

Message Cause Outputs

“P1” Thermostat probe failure

larm output ON; Compressor output according to

parameters “COn” and “COF”

“P3” Probe 3 probe failure Alarm output ON; Other outputs unchanged

“P4” Probe 4 probe failure Alarm output ON; Other outputs unchanged

“HA” Maximum temperature alarm Alarm output ON; Other outputs unchanged

“LA” Minimum temperature alarm Alarm output ON; Other outputs unchanged

"HA2" Condenser high temperature It depends on the “Ac2” parameter

"LA2" Condenser low temperature It depends on the “bLL” parameter

“dA” Door open Compressor and fans restarts

“EA” External alarm Output unchanged.

“CA” Serious external alarm (i1F=bAL) All outputs OFF.

“CA” Pressure switch alarm (i1F=PAL) All outputs OFF

“EE” Data or memory failure Alarm output ON; Other outputs unchanged

The alarm message is displayed until the alarm condition is recovery.

All the alarm messages are showed alternating with the room temperature except for the “P1” which is

flashing.

To reset the “EE” alarm and restart the normal functioning press any key, the “rSt” message is

displayed for about 3s.

12.1 SILENCING BUZZER

Once the alarm signal is detected the buzzer can be silenced by pressing any key. Buzzer is mounted

in the keyboard and it is an option.

12.2 “EE” ALARM

The dIXEL instruments are provided with an internal check for the data integrity. Alarm “EE” flashes

when a failure in the memory data occurs. In such cases the alarm output is enabled.

12.3 ALARM RECOVERY

Probe alarms : “P1” (probe1 faulty), “P3” and “P4”; they automatically stop 10s after the probe restarts

normal operation. Check connections before replacing the probe.

Temperature alarms “HA”, “LA” “HA2” and “LA2” automatically stop as soon as the temperature

returns to normal values.

Alarms “EA” and “CA” (with i1F=bAL) recover as soon as the digital input is disabled.

Alarm “CA” (with i1F=PAL) recovers only by switching off and on the instrument.

13. Technical data

Keyboards

Housing: self extinguishing ABS.

Case: T620: facia 38x185 mm; depth 23mm

V620: facia 72x56 mm; depth 23mm

CX620: facia 75x36 mm; depth 23mm

Mounting: T620: panel mounting in a 150x31 mm panel cut-out with two screws.

∅ 3 x 2mm.

Distance between the holes 165mm

V620: panel mounting in a 56x72 mm panel cut-out with two screws.

∅ 3x2mm. Distance

between the holes 40mm

CX620: panel mounting in a 71x29mm panel cut-out

Protection: IP20; Frontal protection: IP65 with frontal gasket

Connections: Screw terminal block

≤ 2,5 mm

2

Power supply: from XW20K power module

Display: 3 digits, red LED, 14,2 mm high.

Optional output: buzzer

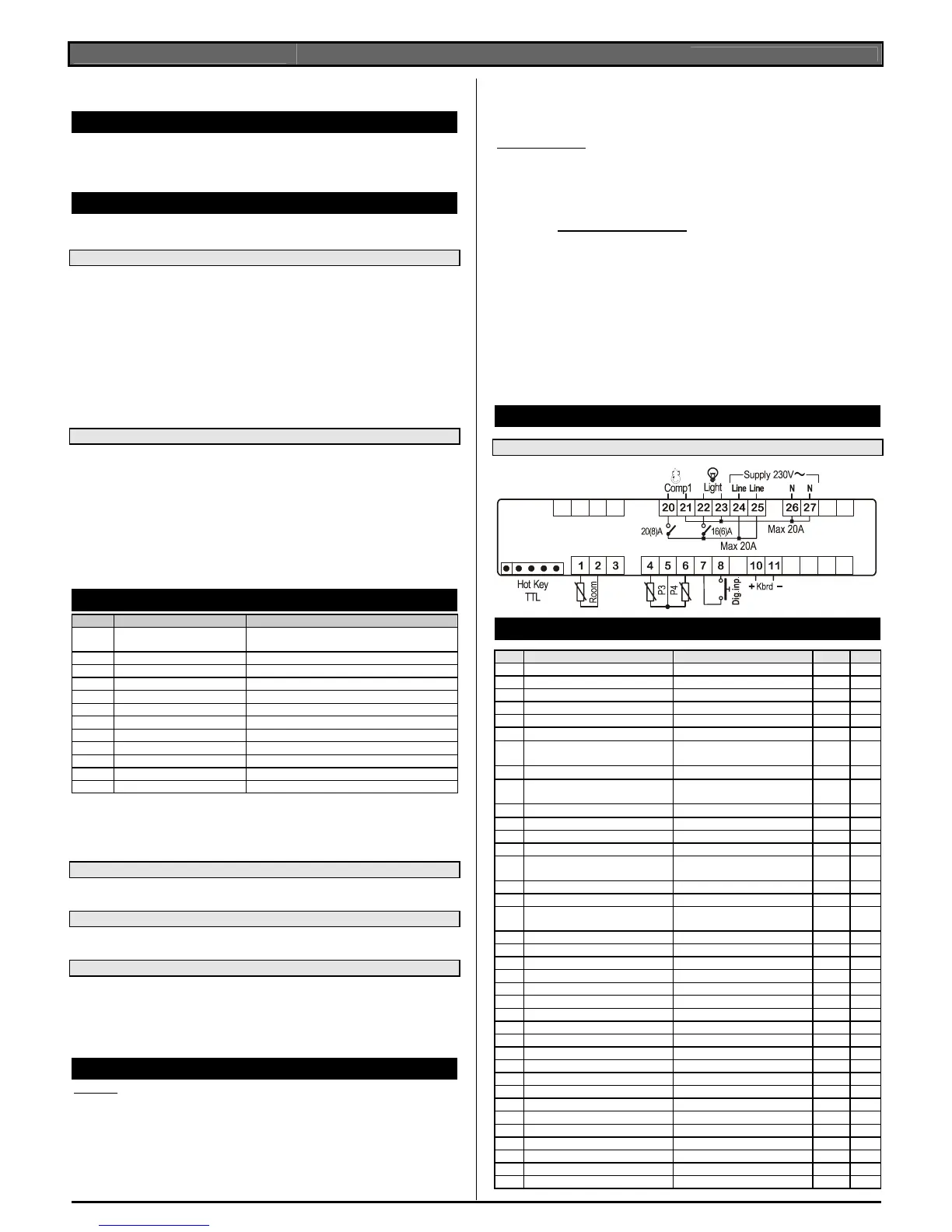

Power module XW20K

Case: 8 DN: 140X176X148.

Connections: Screw terminal block

≤ 2,5 mm

2

heat-resistant wiring and 6,3mm Faston

Power supply: 230Vac or. 110Vac ± 10% or 24Vac

Power absorption: 10VA max.

Inputs: 4 NTC probes

Digital inputs: 1 free voltage

Relay outputs: Total current on loads MAX. 20A

compressor: relay SPST 20(8) A, 250Vac

light (oA3): relay SPST 16(5) A, 250Vac

Serial output : TTL standard.

Communication protocol: Modbus - RTU

Data storing: on the non-volatile memory (EEPROM).

Kind of action: 1B.

Pollution grade: normal

Software class: A.

Operating temperature: 0÷60 °C.

Storage temperature: -25÷60 °C.

Relative humidity: 20

÷85% (no condensing)

Measuring and regulation range: NTC probe: -40÷110°C (-58÷230°F)

Resolution: 0,1 °C or 1°C or 1 °F (selectable).

Accuracy (ambient temp. 25°C): ±0,5 °C ±1 digit

14. CONNECTIONS

14.1 XW20K

15. Default setting values

Label Name Range Default Level

REGULATION

Set Set point LS÷US

3.0 - - -

Hy Differential 0,1÷25,5 °C / 1÷45°F

2.0 Pr1

LS Minimum set point -50,0°C÷SET / -58°F÷SET

-50.0 Pr2

US Maximum set point SET ÷ 110°C / SET ÷ 230°F

110 Pr2

Ot Thermostat probe calibration

-12÷12°C /-120÷120°F

0.0 Pr1

P3P Third probe presence (1st cond.

probe)

n=not present; Y=pres.

n Pr2

O3 Third probe calibration

-12÷12°C /-120÷120°F

0 Pr2

P4P Fourth probe presence (2nd cond.

probe)

n=not present; Y=pres.

n Pr2

O4 Fourth probe calibration

-12÷12°C /-120÷120°F

0 Pr2

OdS Outputs activation delay at start up 0÷255 min.

0 Pr2

AC Anti-short cycle delay 0÷30 min.

1 Pr1

Ac1 Second compressor delay 0÷255s

5 Pr2

CCt Compressor ON time during fast

freezing

0 ÷ 23h 50 min.

0.0 Pr2

CCS Set point for continuous cycle (-55.0÷150,0°C)

3 Pr2

COn Compressor ON time with faulty probe 0÷255 min.

15 Pr2

COF Compressor OFF time with faulty

probe

0÷255 min.

30 Pr2

CH Kind of action CL=cooling; Ht= heating

cL Pr1

DISPLAY

CF Temperature measurement unit °C ÷ °F

°C Pr2

rES Resolution (integer/decimal point) in ÷ de

dE Pr1

rEd Remote display P1 ÷ 1r2

P1 Pr2

dLy Display temperature delay 0 ÷ 20.0 min (10 sec.)

0 Pr2

DEFROST

dFP Probe selection for defrost termination nP; P1; P2; P3; P4

nP Pr2

dtE Defrost termination temperature -50,0÷110°C / -58÷230°F

0 Pr2

IdF Interval between defrost cycles 1÷120h

8 Pr1

MdF (Maximum) length for 1° defrost 0÷255 min.

20 Pr1

dFd Displaying during defrost rt, it, SEt, dEF, dEG

it Pr2

dAd MAX display delay after defrost 0÷255 min.

30 Pr2

AUXILIARY THERMOSTAT

ACH Kind of action for auxiliary relay CL; Ht

cL Pr2

SAA Set Point for auxiliary relay -50,0÷110°C / -58÷230°F

0,0 Pr2

SHy Differential for auxiliary relay 0,1÷25,5 °C / 1÷45°F

2,0 Pr2

ArP Probe selection for auxiliary relay nP / P1 / P2 / P3

nP Pr2

Sdd Aux.output working during defrost n, y

n Pr2

ALARMS

Loading...

Loading...