10

UNPACKING & INSTALLATION

Air Supply Connection

e MEK Rub Test machine is supplied with a 2 stage air lter assembly pre-installed on the back of the unit,

bypassing or removal of these lters will void the machine warranty, if problems due to lters plugging up occur

the air supply problem should be addressed before continuing use of the machine.

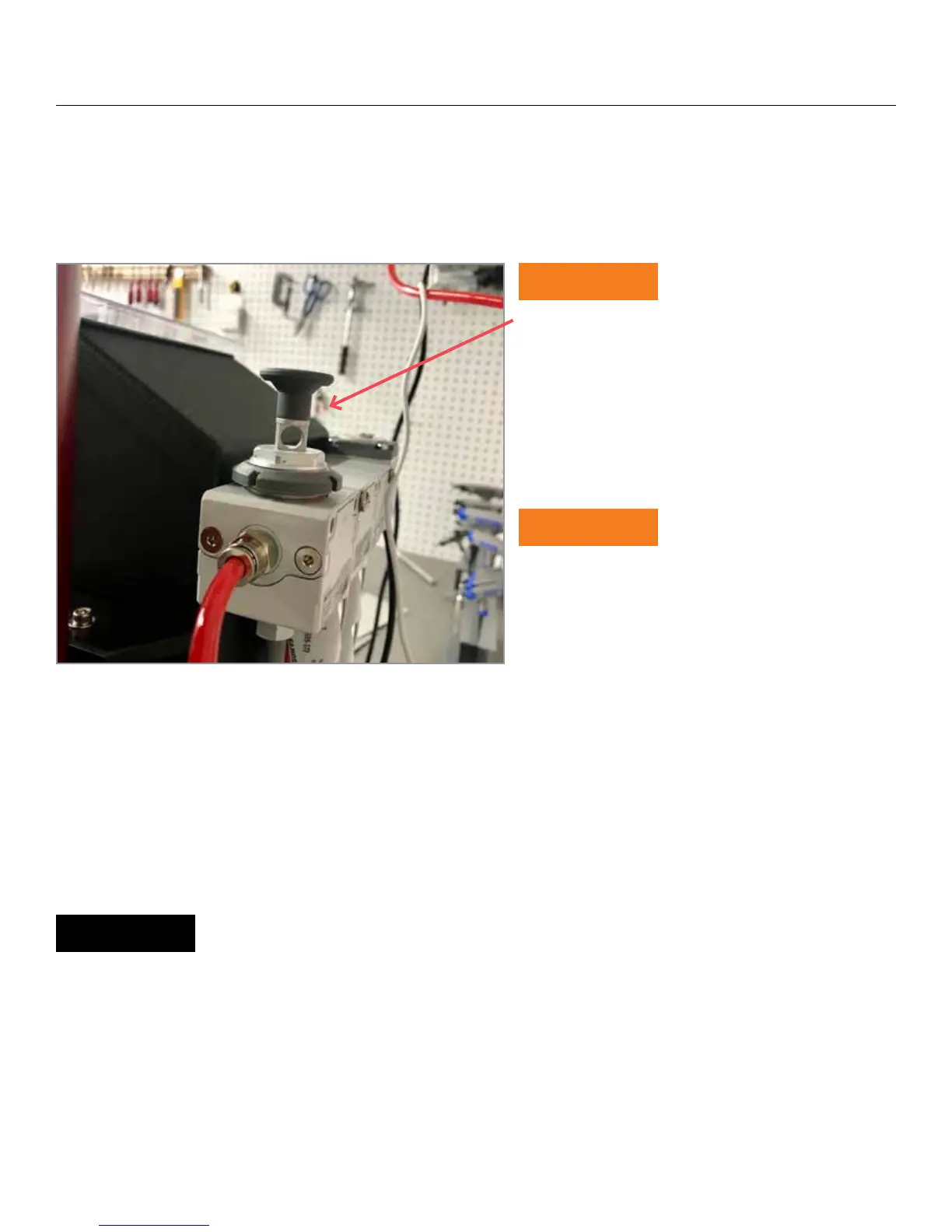

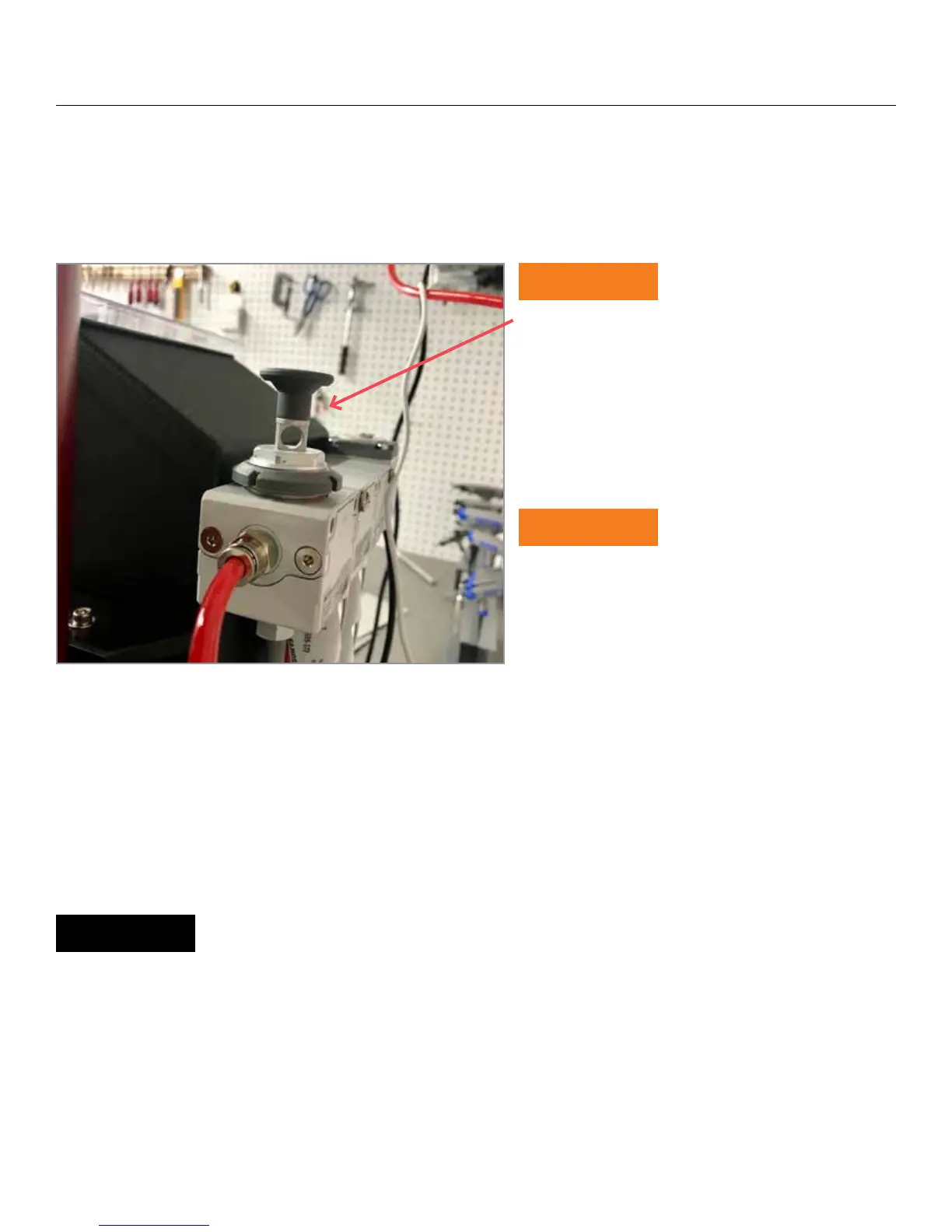

Air Supply shuto, before connecting the airsupply

to the machine make sure that the machine airshut

o valve is in the closed position. (Pull up on the

handle to shuto air supply)

Connect the air supply to the inlet side of the lter

assembly

Clean, dry, oil free air only, any use of oiler’s or dirty

air supply will void your warranty. Use of synthetic

oils in the air supply can cause severe damage to

the internal valve seals and must be avoided

Once the air supply has been connected push the handle on the top of the lter assembly down to supply air the

machine pneumatics, check the pressure gauge (located in regulator) on the tower face on the front of the machine.

e correct operating pressure is 80 psi (550 Kpa). If the pressure is not correct adjust the regulator to the correct

pressure.

Correct operating pressure is important to achieving accurate test results, incorrect pressure

will eect the number of strokes/min. Set pressure to 80 psi (550 Kpa) setting is done statically

do not try to adjust the pressure while the machine is running.

CAUTION

CAUTION

NOTE

Loading...

Loading...