(No.HD003<Rev.004>)1-43

(10) Cam Mo-Platen (Heater Cam Motor - Platen)

The heater cam motor rotates, keeps pressing the platen

for about 3 seconds, leaves the platen, then goes back to

the standby position.

(11) Cam Mo-HR (Heater Cam Motor - Heat Roller)

The heater cam motor rotates, keeps pressing the heat roll-

er for about 3 seconds, leaves the heat roller, then goes

back to the standby position.

5.3.3.2 Sensor

Correct operation of the sensor is checked. Confirm the valve is

changed, when the sensor is interrupted or reflected.

5.3.3.3 Memory

The picture memory SDRAM on the Main PWB is tested. The

buzzer sounds in case of an error. The error LED also will light.

5.3.3.4 Display

All the dots of LCD are displayed black. Confirm that there is no

missing dot.

5.3.3.5 Back Color

The back colors red, green, and blue are displayed for 3 seconds

and correct display of the back colors is tested.

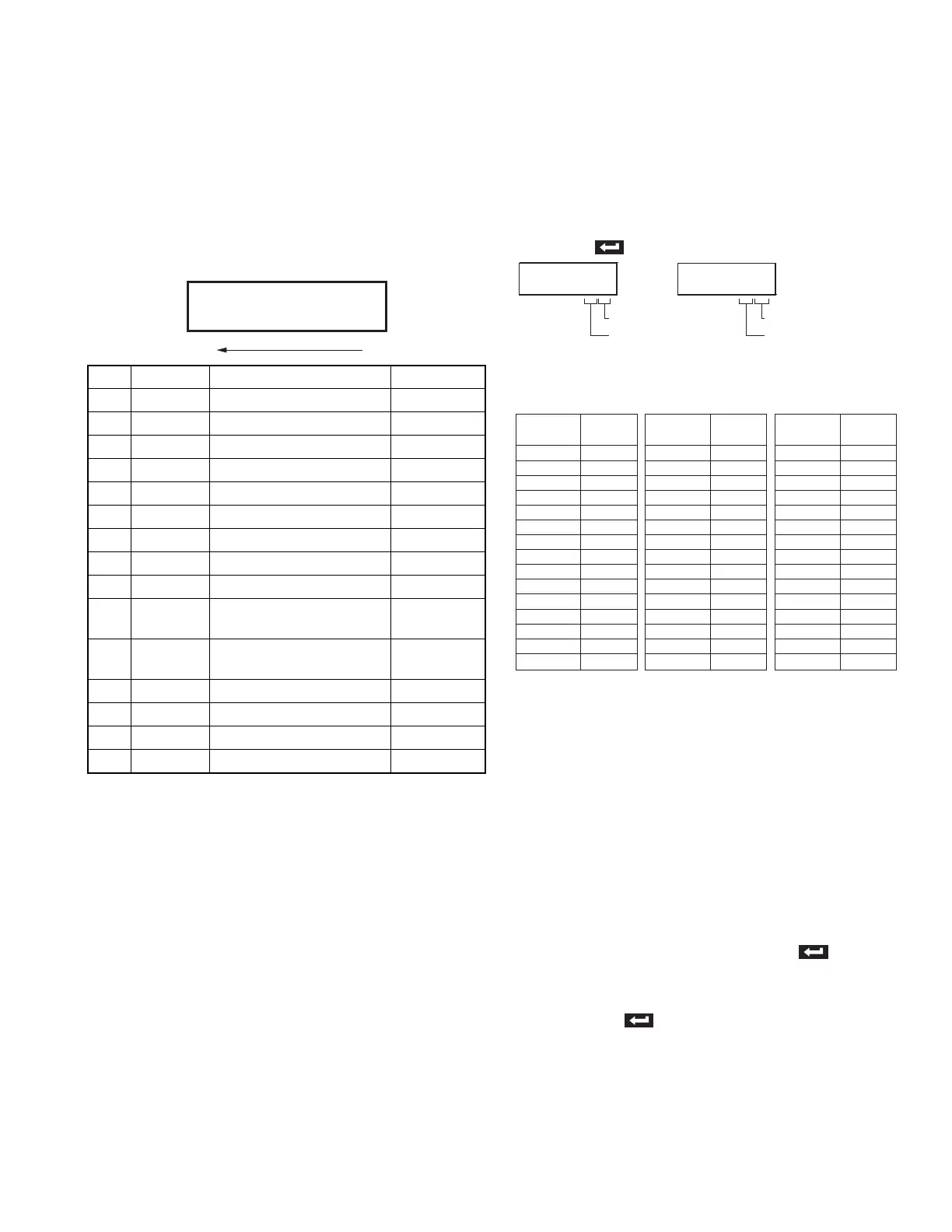

5.3.3.6 Registers

This printer has four temperature-detecting thermistors:

(1) Retransfer heat roller thermistor

(2) Bend remedial heat roller thermistor

(3) Thermal head thermistor

(4) Ambient temperature thermistor

These thermistors output analog signals, which are applied to the

circuits for four channel 8bit A/D converter IC.

Each of these converted value in a hex decimal number as

shown below. Note that the following values are the values at the

moment the [ ] button is pressed.

The following table shows reference values.

5.3.4 Information

The information for the various firmware versions can be con-

firmed. For the thermal head, the serial No. and the head supply

voltage (Vth) are displayed.

And the total lighting time of the heaters (retransfer and bend

remedy) can be displayed. And it is possible to clear the total

lighting time to zero after replacing those heaters.

5.3.4.1 Assistance

The management data used when producing this printer.

5.3.5 Push and Pop

This printer has two EEPROMs for storage of data for the thermal

head and for user and service mode.

When the Main PWB is exchanged, the settings for user and ser-

vice mode must be done over again. The Parameter Push/Pop

function is provided to shorten this operation.

When initially "Push" is selected and the [ ] button is

pressed, the set values (including head, total counter) in the EE-

PROM on the Main PWB are written to the EEPROM in the head.

When then "Pop" is selected after the Main PWB has been ex-

changed and the [ ] button is pressed, these set values are

copied to the EEPROM on the Main PWB.

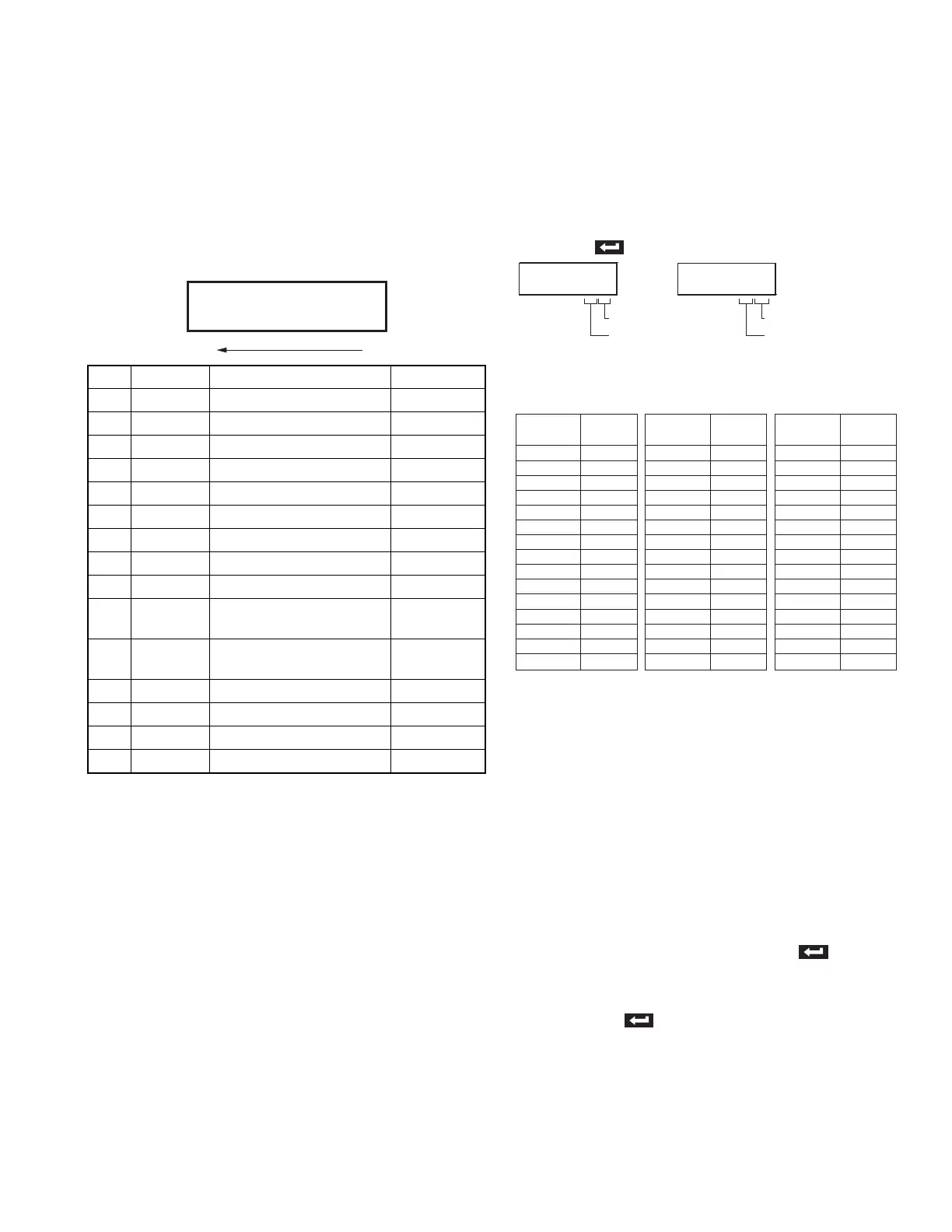

D0 NOCD Card existence Reflection : 0

D1 ICPOS IC Card position Reflection : 0

D2 MGCDPOS MG Card position Reflection : 0

D3 MGHDPOS MG Head position Reflection : 0

D4 TURNPOS Turnover initial position Reflection : 0

D5 EDGE Card edge Reflection : 0

D6 CDOUT Card outlet Reflection : 0

D7 Not used

D8 INK Ink start position Interruption : 0

D9 MEDIA Film mark Reflection : 0

D10 CAM A Retransfer heat roller/Platen

roller position

Reflection : 0

D11 CAM B Retransfer heat roller/Platen

roller position

Reflection : 0

D12 Not used

D13 Not used

D14 Not used

D15 Not used

>>

Sensor

D15 D0

0000011001111010

>>ADPORT0

C277

>>ADPORT1

FCFC

Ambient temperature

Thermal head

Retransfer heat roller

Bend remedial heat rolle

Temperature

(

O

C)

0

20

50

80

100

130

140

150

160

170

180

190

200

210

220

Indicated

Value

FE

FC

F5

E2

CC

9E

8D

7D

6D

5E

51

46

3B

33

2B

Temperature

(

O

C)

-5

0

10

15

20

25

30

35

40

45

50

55

60

65

70

Indicated

Value

E7

E0

CD

C1

B3

A5

96

87

78

6A

5C

50

45

3B

32

Temperature

(

O

C)

0

5

10

15

20

25

30

35

40

45

50

55

60

65

70

Indicated

Value

E8

E2

DB

D3

C9

BF

B4

A8

9C

90

83

77

6C

61

57

Heat roller

thermistors

Ambient temperature

thermistor

Thermal head

thermistor

Loading...

Loading...