17

E

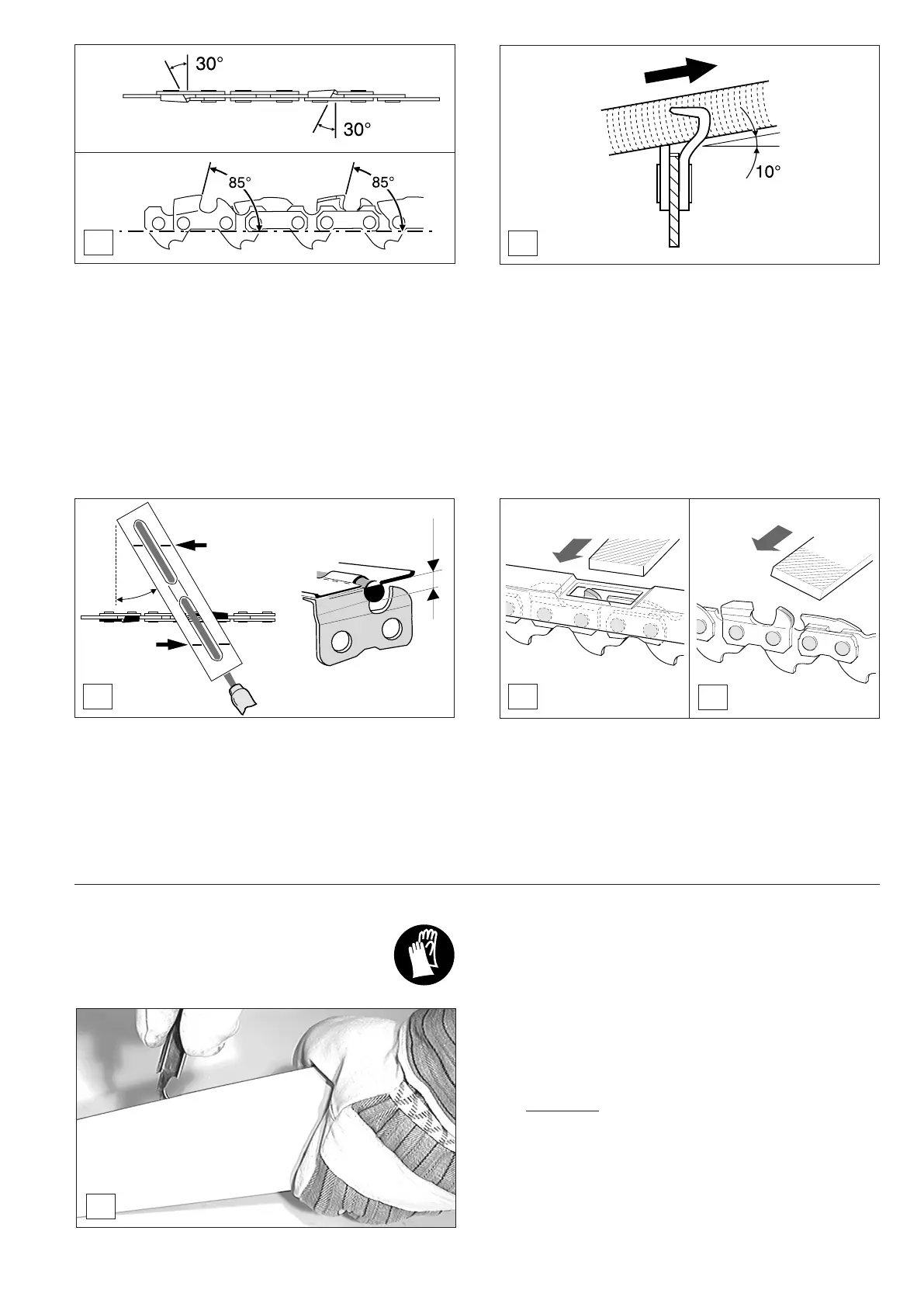

Files and how to work with them

‑ Sharpen using a special le holder with a saw chain round le.

File the rst cutter half with a 4.8 mm dia. round saw‑chain

le, then switch to a 4.5 mm dia. le. Normal round les

are not appropriate for this work. See "Accessories" for the

order number.

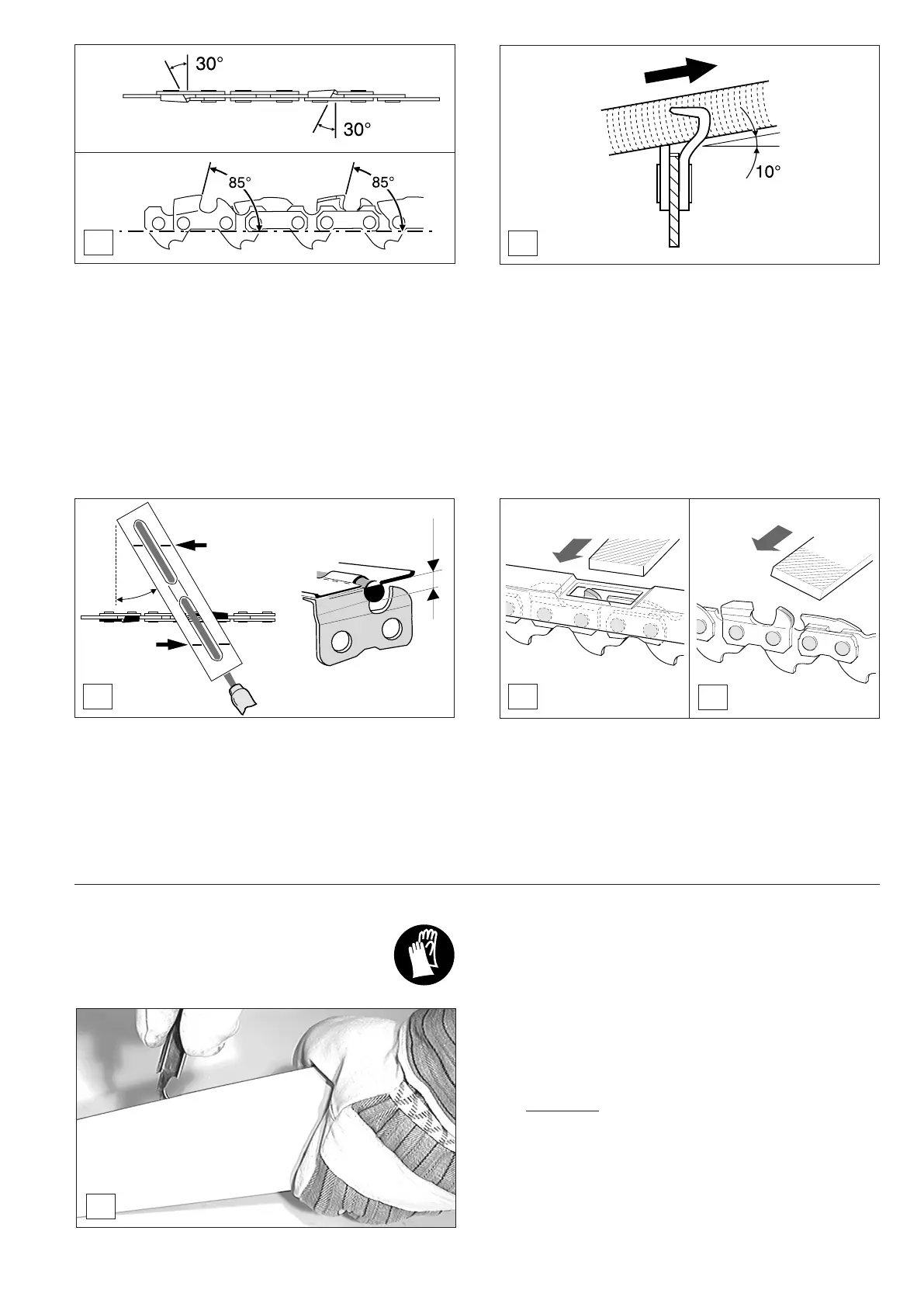

‑ The le should cut only when pushed forwards (arrow).

Lift the le when leading it backwards.

‑ First sharpen the shortest cutter. The length of this cutter

is then the standerd for all other cutters of the chain.

‑ Always guide the le horizontally (10

o

to the guide bar).

‑ All cutters must be sharpened to the same angle, 30°. Dif

‑

ferent angles result in a roughly, irregularly running chain,

increase wear and tear and cause chain beakage.

‑ The 85° front rake of the cutter results from the cut depth of

the round le. If the proper le is used in the right manner,

the correct front rake will be obtained automatically.

F

G

H

‑ After having sharpened the chain, the height of the depth

limiter must be checked by means of a chain gauge. See

"Accessories" for the order number.

‑ Correct even the smallest excess height with a special at

le (

H). See "Accessories" for the order number.

‑ Round off the front of the depth limiter (

I).

‑ The le holder makes le guidance easier. It is marked for

the correct 30° sharpening angle (keep the marks parallel

with the chain when ling, see illustration) and limits the

cut depth to the correct 4/5 of the le diameter. See "Acces‑

sories" for the order number.

30°

4/5

I

Cleaning the guide bar,

lubricating the sprocket nose

CAUTION:

Protective gloves must be worn!

J

Regularly inspect the bearing surfaces of the guide bar for dam‑

age, and clean them with a suitable tool.

If the saw is used intensively it will be necessary to lubricate

the return sprocket bearings regularly (once a week). To do this,

rst thoroughly clean the 2 mm hole at the tip of the guide bar,

and then press in a small amount of multi‑purpose grease.

Multi‑purpose grease and grease guns are available as

accessories.

Multi‑purpose grease (order no. 944 360 000)

Grease gun (order no. 944 350 000)

Loading...

Loading...