13

❖

English

L-2091 Operation

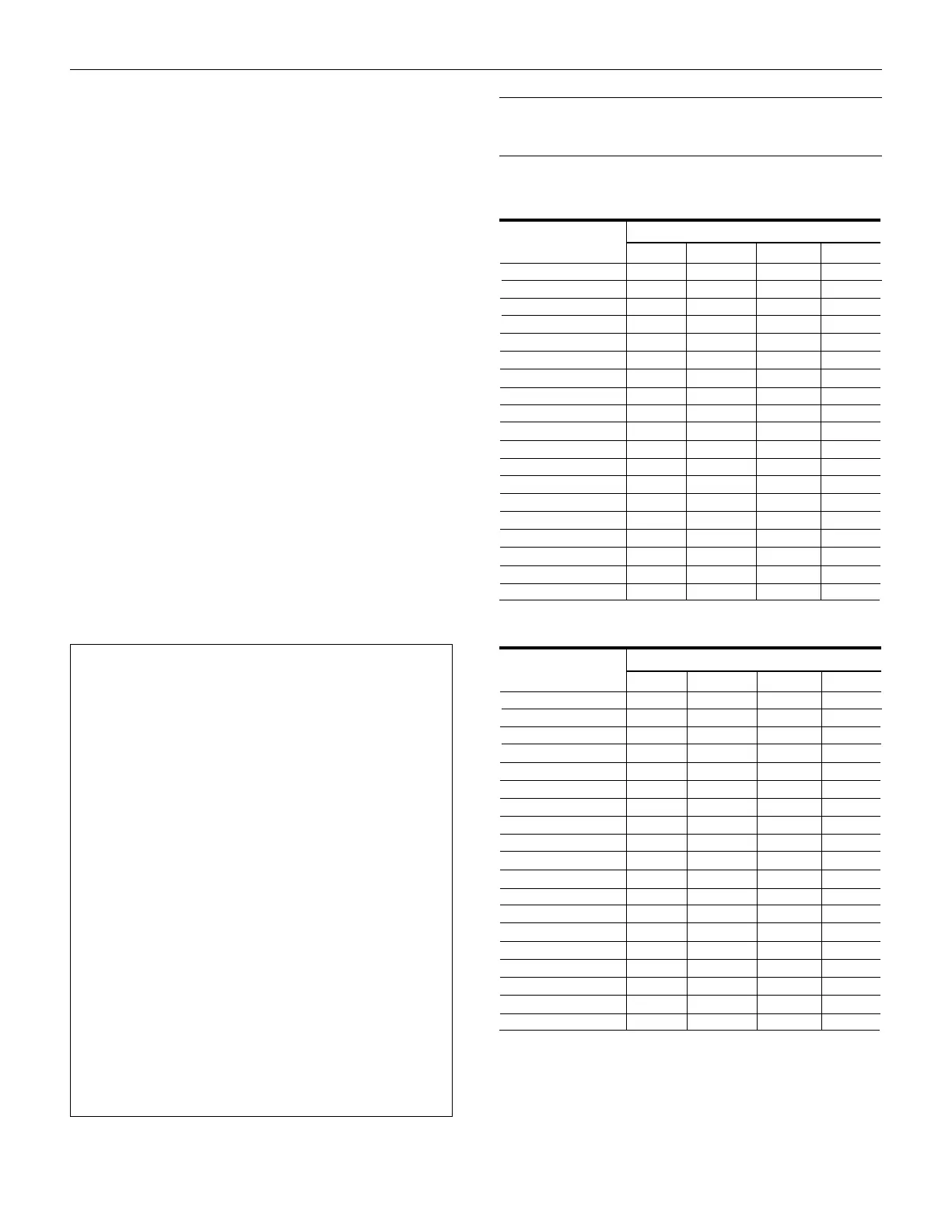

BTU Guide - Refrigeration Loss/Gain

Specs

BTU loss per hour for various capacity boxes at 100°F

difference between inside and outside temperature.

Digital Thermostat Display Error Messages

E1- Appears when either the up or down key is pressed

when not in the programming mode.

To correct: If the E1 message appears even when

no keys are being pressed, replace the control.

E2- Appears if the control settings are not properly stored

in memory.

To correct: Check all settings and correct if neces-

sary.

EP- Appears when the probe is open, shorted or sensing

a temperature that is out of range.

To correct: Check to see if the sensed temperature

is out of range. If not, check for probe damage by

comparing it to a known ambient temperature be-

tween -30°F and 220°F. Replace the probe if neces-

sary.

EE- Appears if the EEPROM data has been corrupted.

To correct: This condition cannot be fi eld repaired.

Replace the control.

CL- Appears if calibration mode has been entered.

To correct: Remove power to the control for at least

fi ve seconds. Reapply power. If the CL message still

appears, replace the control.

Box Internal Insulation Thickness (R-7 Foam)

Volume (cubic ft)

1" 2"

3" 4"

1 136 89 75 69

2

201 126

102 92

3

256 156

125 110

4

308 184

145 127

5

350 207

161 140

6 388 229 177 153

7

428 250

192 165

8

464 267

206 176

9

500 289

220 187

10

532 306

232 197

11 565 323 244 206

12

596 340

256 216

13

626 356

267 225

14

655 371

278 233

15

684 387

290 242

20 902 505 374 310

25

1040 577 424 350

30

1178 649 475 389

35

1316 721 525 428

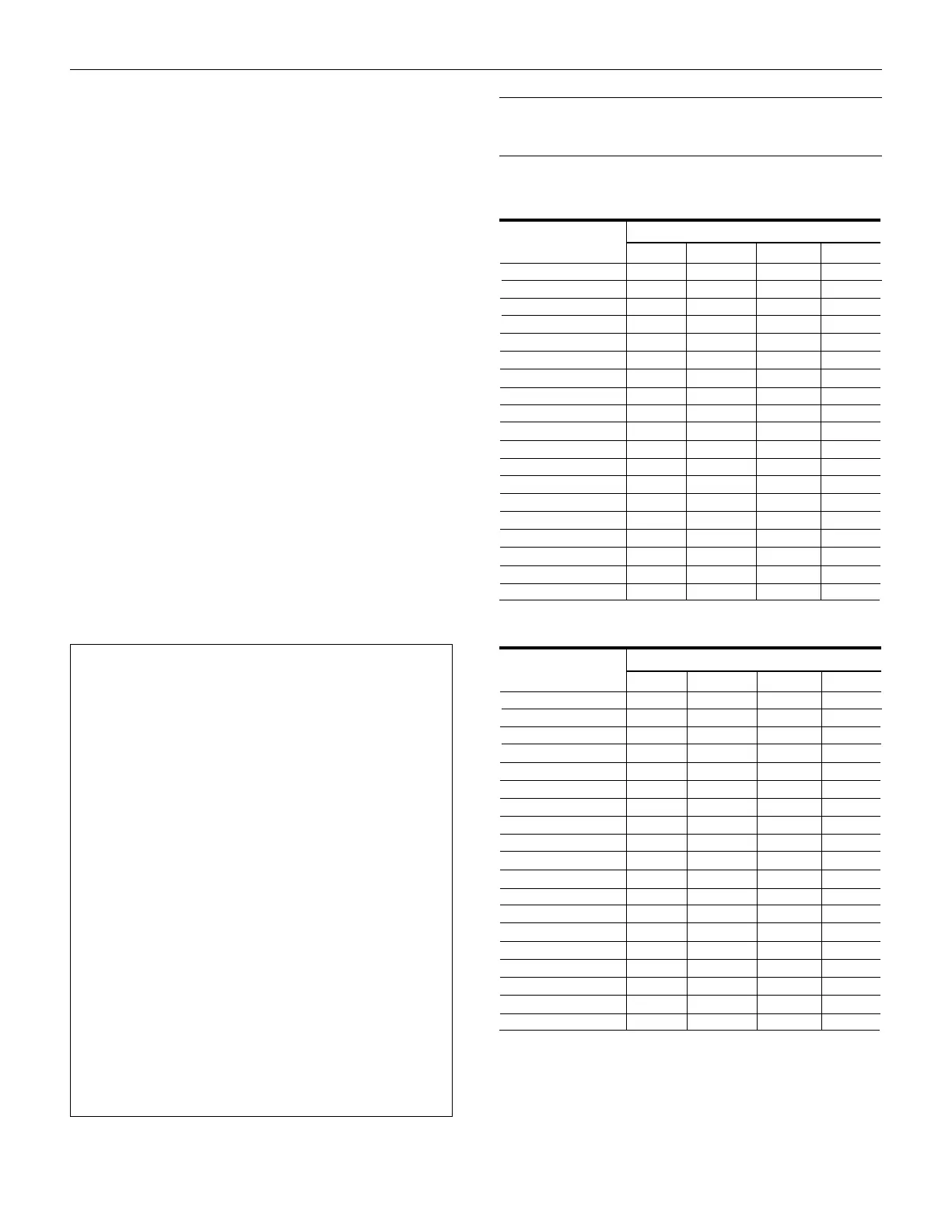

Box Internal Insulation Thickness (R-5 Foam)

Volume (cubic ft)

1" 2"

3" 4"

1 190 124 105 97

2

282 176 143 128

3 359 219 174 154

4

441 264 208 182

5 496 294 229 199

6

551 323 250 215

7 602 351 270 231

8

651 378 289 247

9 699 403 307 261

10

745 428 325 275

11 790 452 342 289

12

832 475 358 301

13 875 497 374 314

14

917 520 390 327

15 958 542 405 339

20

1147 642 476 395

25 1323 734 540 445

30

1499 826 604 495

35 1675 918 668 545

9. High condensing temperature.

High ambient temperature – introduce cooler air into

compar

tment that houses the condensing unit.

High water temperature – while y

ou cannot remedy

this prob

lem, you can help by

introducing cooler air

into the compar

tment that houses the condensing

unit.

Pump not oper

ating – fi nd cause and remedy.

Condenser fan failure – replace component.

10. Improperly mounted temperature sensor in re-

frigerated box.

Refer to Installation section for proper location of

sensor

. If drilling in a wrapped bo

x, be sure to

confi

rm placement of evaporator lines before drilling.

This can be accomplished by tur

ning the condensing

unit on, and chec

king for frost lines in the box.

11. Moisture in system.

Have a certifi ed technician check for this problem.

If there is moisture present, he/she will decide a

course of action to tak

e which should include:

leak

chec

k, installation of liquid line fi lter/dryer, evacua-

tion, and recharging. Unit should be checke

d at later

date f

or any remaining moisture.

12. Inadequate design.

Not every box is designed for every condition. It may

be that y

our box was not designed properly.

If this is

the prob

lem, replacement of the bo

x or condensing

unit ma

y be the only solution.

Loading...

Loading...