Power Train Disassembly & Assembly

Adjust the wheel Bearing

Preload

NOTE : To adjust the wheel bearing preload, the

bearings must be seated and the rollers in proper

alignment.

Use a brass or leather mallet for assembly and

disassembly procedures. Do not hit steel parts

with a steel hammer. Pieces of a part can break off

and cause serious personal injury.

1. Install the wheel bearing adjusting nut (16).

Tighten the nut 400 lb•ft (542 N•m).

2. Rotate the hub (24) in both directions. At the same

time, rap the hub several times with a brass or

plastic mallet.

3. Tighten the nut to 400 lb•ft (542 N•m) again.

4. Back off the nut approximately 1/4 turn to relieve

the preload produced in Step 3.

5. Tighten the nut to 200 lb•ft (271 N•m).

NOTE : If you move the adjusting nut to align the

lock plate mounting holes, advance or tighten the

nut. Do not loosen or back off the nut.

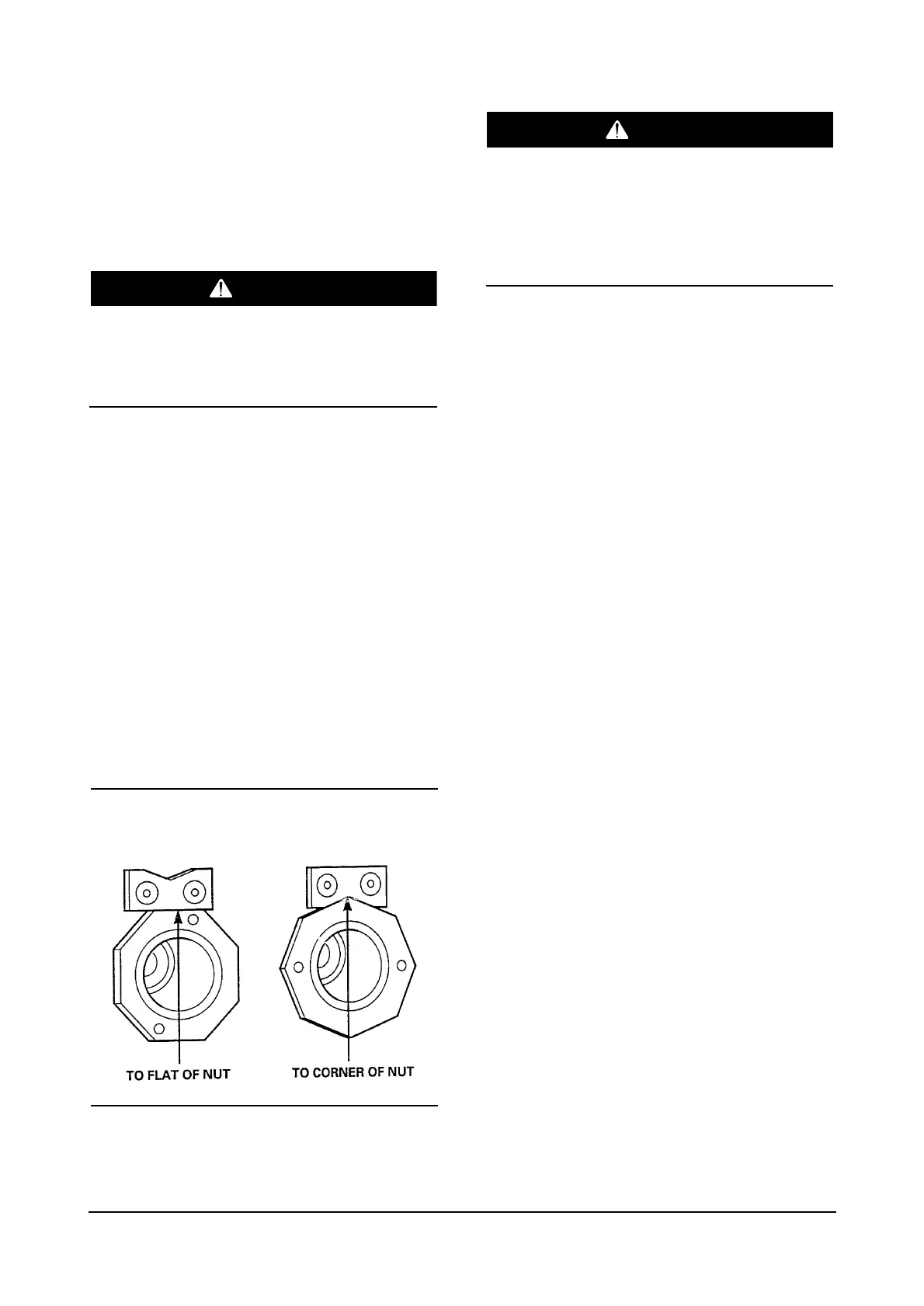

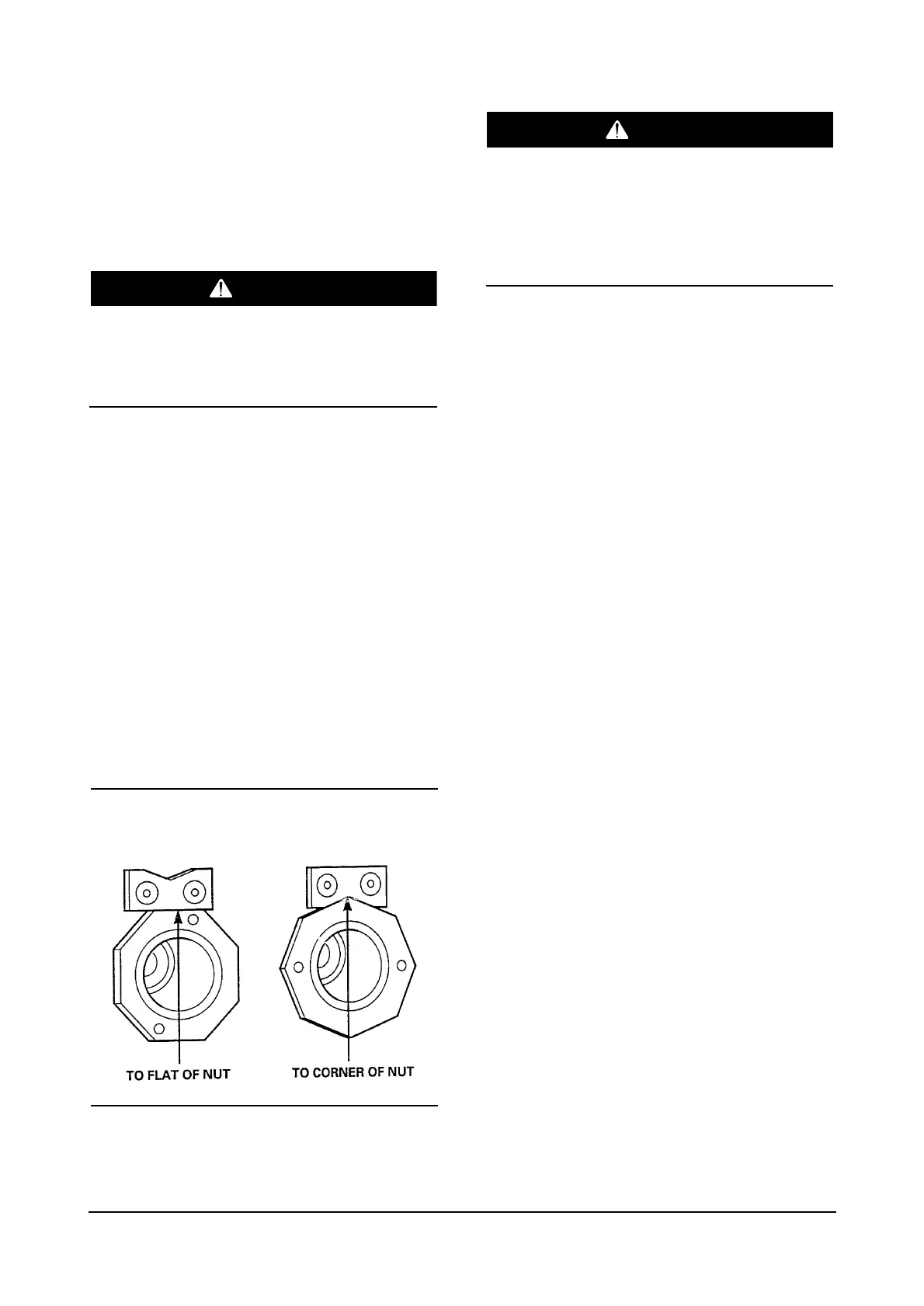

6. Install the lock plate (19) to either a nut flat or nut

corner.

Take care when using Loctite to avoid serious

personal injury. Follow the manufacturer’s

instructions to prevent irritation to the eyes and

skin. If Loctite gets into your eyes, flush them with

water for 15 minutes. Have your eyes checked by

a doctor as soon as possible.

7. Install the lock plate mounting screw (18). Tighten

the mounting screws to 20-30 lb•ft (27-41 N•m).

a. New lock plate mounting screw threads come

equipped with a pre-applied locking agent.

b. If the original lock plate mounting screws (18)

are used, apply two or three drops of Loctite

277 or equivalent to the internal threads of the

ring gear hub (20).

8. Apply axle grease to the inner face of the sun gear

thrust washer (15) to help retain the washer to the

nut.

9. Install the sun gear thrust washer (15) so that the

washer tangs must engage the slots in the bearing

adjusting nut (16).

10. Install the planetary sun gear (14) and snap ring

(13) onto the axle shaft (33).

11. Install the axle shaft and sun gear assembly (33,

14, 13).

•

The axle shaft must engage the differential side

gear.

•

The sun gear must make contact with the thrust

washer (14).

•

The thrust washer tangs must be properly engaged

in the ring gear hub holes.

Loading...

Loading...