Power Train Disassembly & Assembly

Inspect Parts

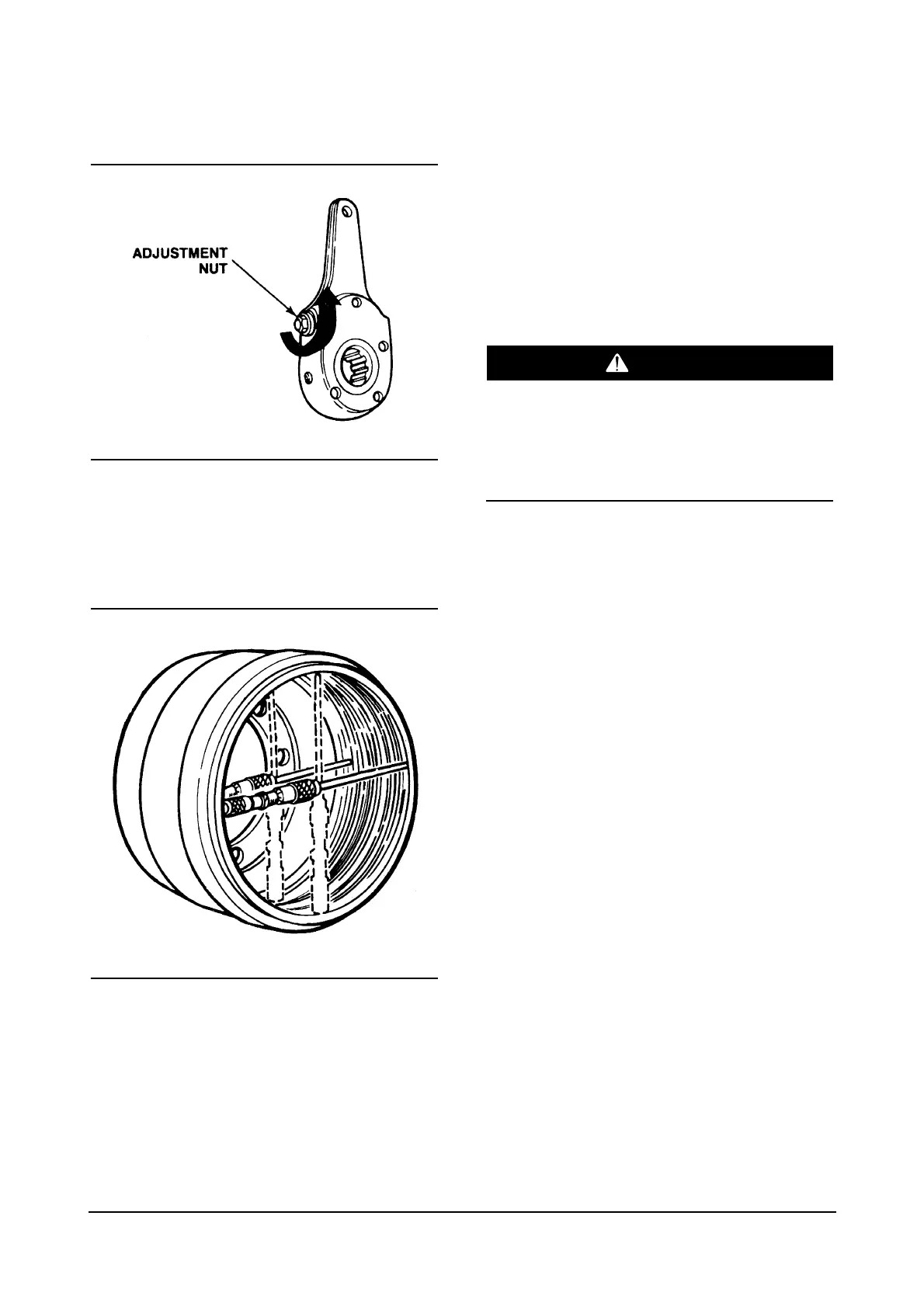

1. Check the slack adjusters:

Rotate the adjustment nut on the worm shaft to

make sure that the worm drive is free. Replace the

slack adjuster if the worm drive does not operate

correctly. Do not repair a manual slack adjuster.

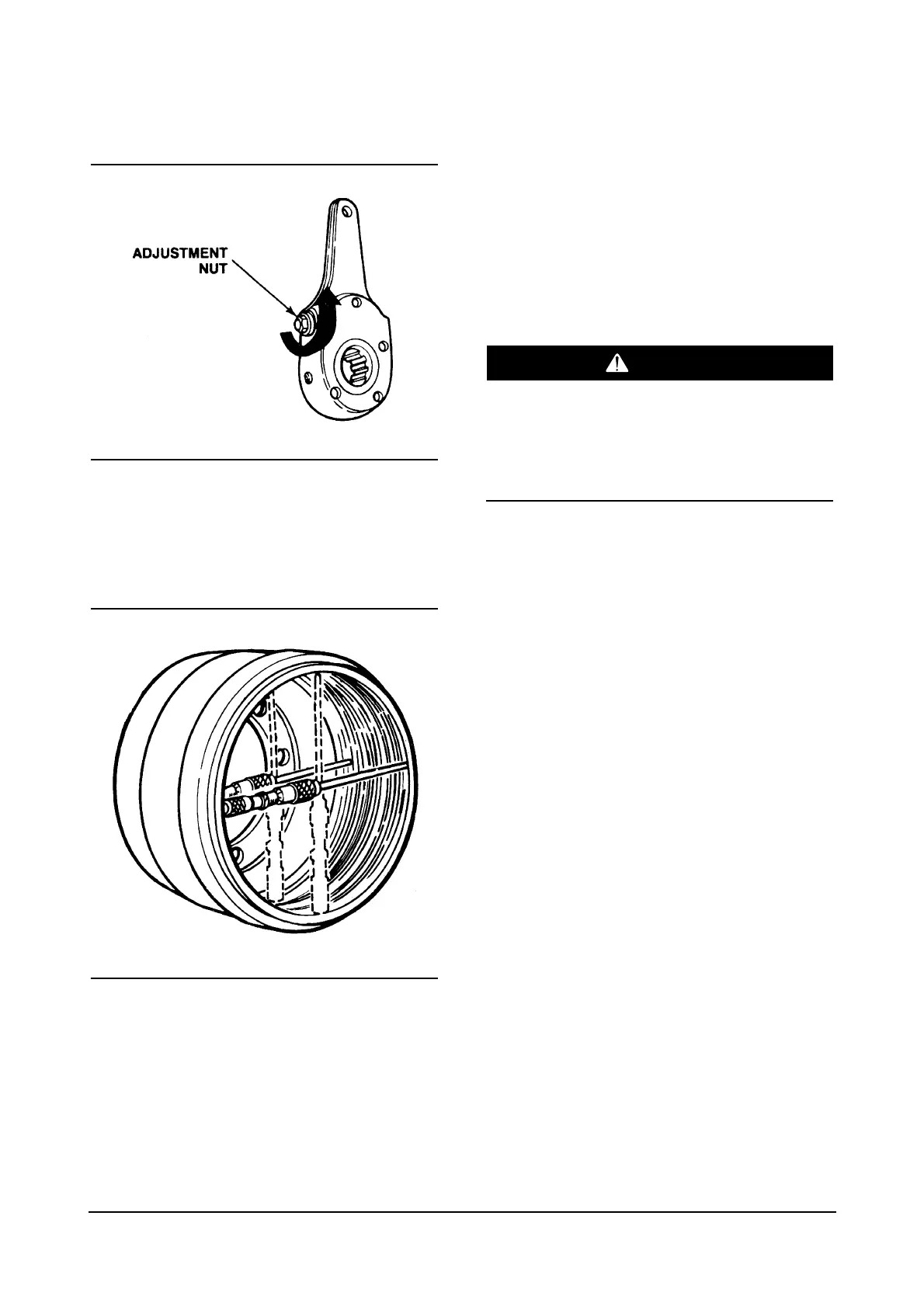

2. Check the drums:

A. Check the brake drums for cracks, severe heat

checking, heat spotting, scoring, pitting and

distortion. Replace drums as required. Doosan

recommends that you do NOT turn or rebore

brake drums because it decreases the strength

and heat capacity of the drum.

B. Measure the inside diameter of the drum in

several locations with a drum caliper or internal

micrometer. Replace the drum if the diameter

exceeds the specifications.

Do not operate the vehicle with the brake drum

worn or machined beyond the dimension

indicated on the drum. The brake system may not

operate correctly. Damage to components and

serious personal injury can result.

3. Check dust shields for rust and distortion. Repair

or replace damaged shields as necessary.

Loading...

Loading...