Power Train Disassembly & Assembly

Recommended Periodic

Service

1. Brake Adjustment – when the air chamber stroke

exceeds the limits shown below.

NOTE : The adjusting bolt on some manual slack

adjusters can reach the limit of its adjustment before

the linings are completely worn. To get additional

adjustment, do the following:

A. Completely retract the brakes.

B. Remove the slack adjuster.

C. Turn the camshaft to force the brake shoes apart.

Install the slack adjuster so that its arm is one

spline closer to the clevis than before.

D. Adjust the brake.

2. Lubrication – lubricate the brake and slack

adjuster.

3. Minor Inspection – at each lubrication.

4. Brake Reline – when the thickness of the lining is

1/4 inch (6.3 mm) at its thinnest point.

5. Drums – check at reline.

6. Major Inspection – at each reline.

7. Complete Overhaul – at every second reline or as

required.

A schedule for the periodic adjustment, cleaning,

inspection and lubrication of the brake equipment

must be made according to experience and the type

of operation.

Brakes must be adjusted as frequently as required

for correct operation and safety. The adjustments

must give correct clearance between the lining and

drum, correct pushrod travel and correct balance

between the brakes.

CAUTION : Do not let brake lining wear to the point

that the rivets or bolts touch the drum. Damage to

the drum will occur.

NOTE : Correctly adjust wheel bearings before

adjusting the brake.

Brakes must be cleaned, inspected, lubricated and

adjusted every time the wheel hubs are removed.

During a major overhaul, the following parts must be

carefully checked and replaced with genuine Doosan

Replacement Parts if required:

1. Backing plates or spiders for distortion and loose

bolts

2. Anchor pins for wear and correct alignment

3. Brake shoes for wear at anchor pin holes or roller

slots

4. Camshaft and camshaft bushings for wear

5. Shoe return springs must be replaced

6. Brake linings for grease on the lining, wear and

loose rivets or bolts

7. Drums for cracks, deep scratches or other

damage.

To help ensure maximum lining life, Doosan

recommends that springs, rollers, and anchor pins be

replaced at each reline.

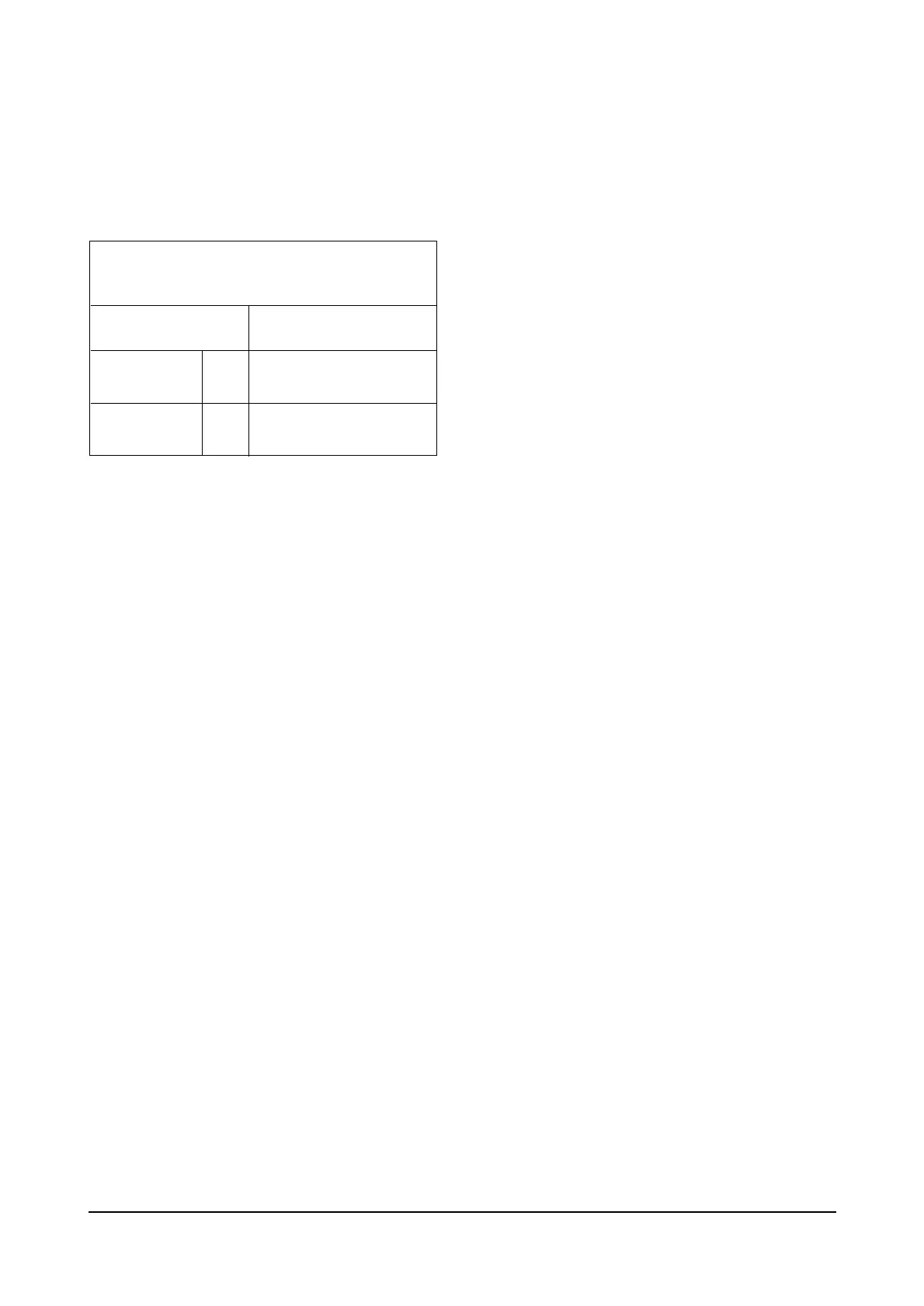

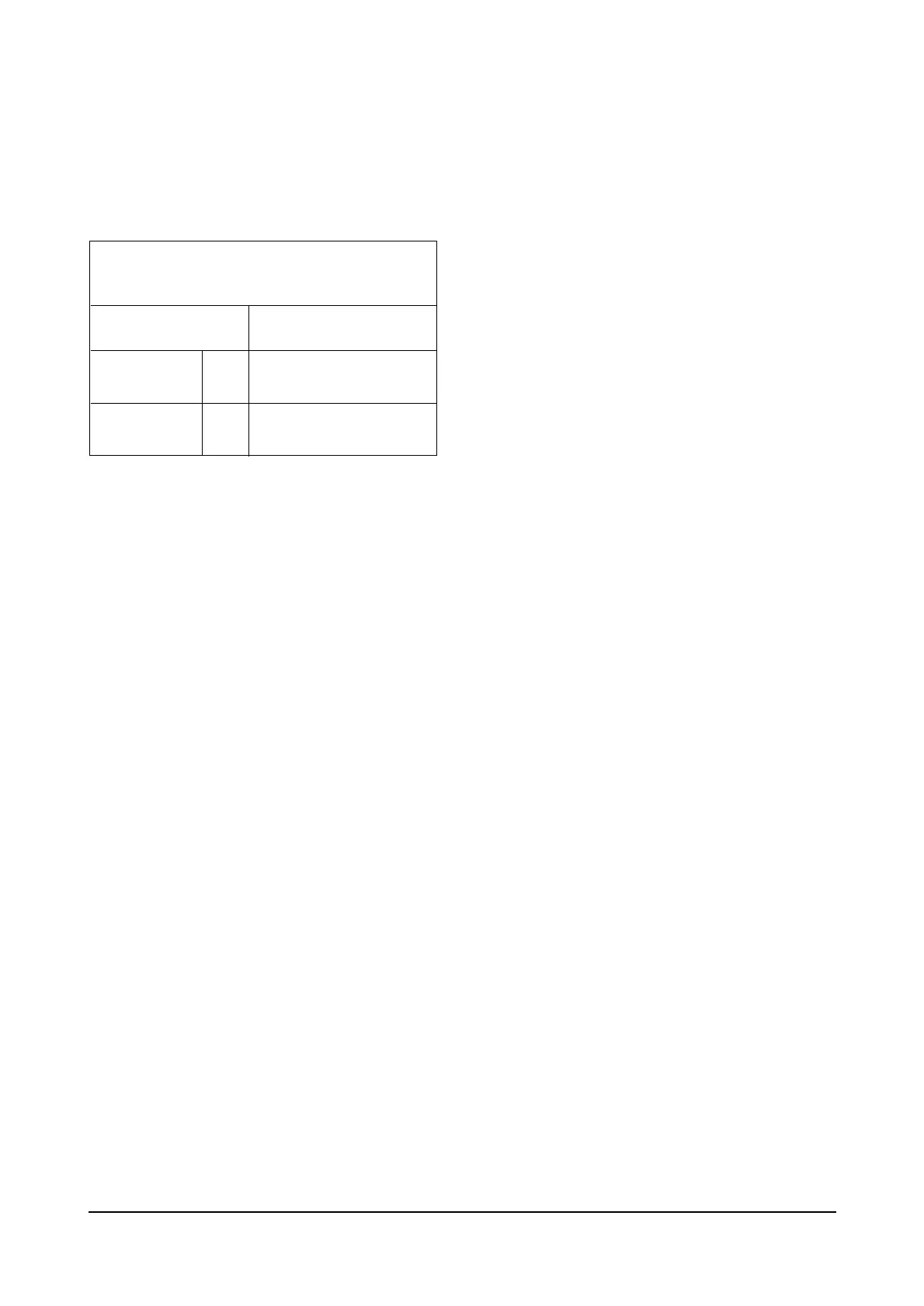

Maximum Stroke at Which Brake Must be Adjusted.

80 - 90 PSI (550-620 kPa) Air Pressure In the Air

Chamber. Clamptype Air Chamber.

Chamber Stroke Length

Type (Size) Not to Exceed :

D100/120

30 2inches (50.8 mm)

D110/130S-5

D150

36 2-1/4 inches (57.1 mm)

D160S-5

68

Loading...

Loading...