4. Regular inspection

64

7) After 400 hours of operation turn the cylinder head bolts

by a further 90°(1/4 revolution).

Cylinder Compression Pressure

1. Start and warm up the engine.

2. Stop the engine and disassemble the fuel injection nozzle

holder assembly.

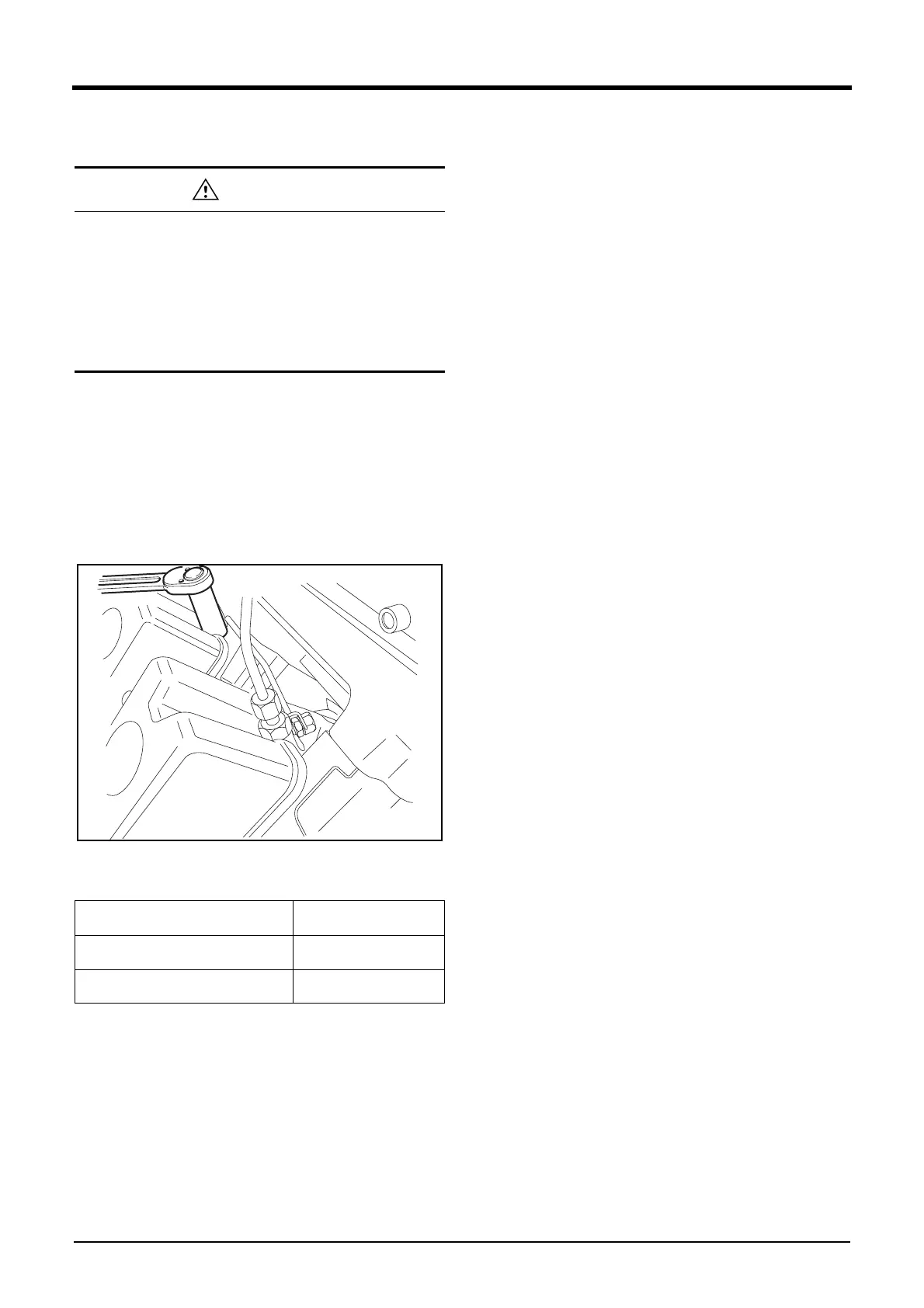

3. Install a special tool, compression pressure gauge

adapter (EU.2-0532), in the fuel injection nozzle holder

hole.

DV2213046A

4. Connect the compression pressure gauge to the adapter.

• The two outside screws (intake and exhaust side)

must not be retightened.

• The cylinder head bolts to be retightened must not

be loosened first, but simply tightened by a further

90°(1/4 revolution) from their actual position.

• when a cylinder head has been removed the

cylinder head gasket must always be changed.

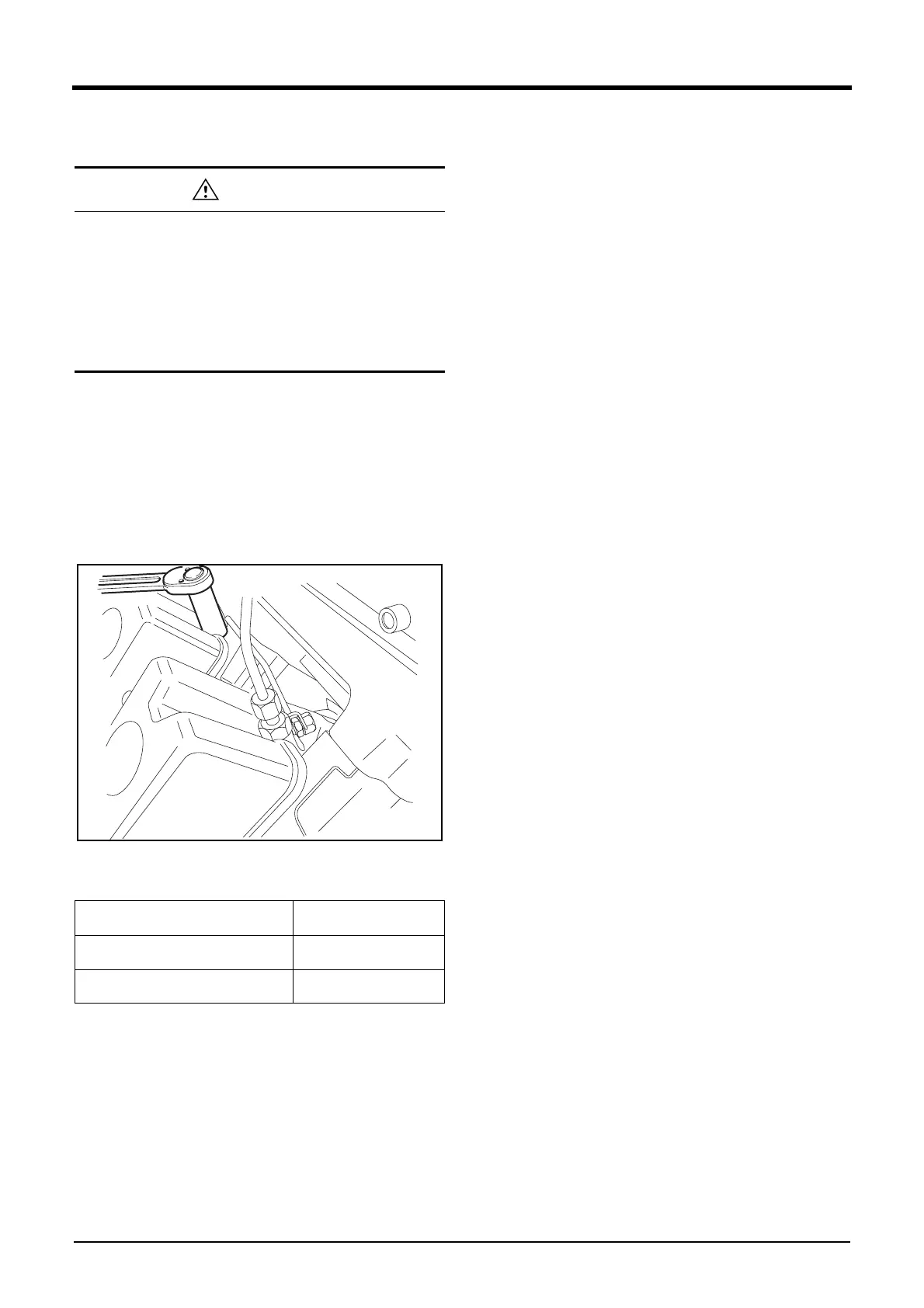

Standard

Above 28kg/cm

2

Tolerance limit

24kg/cm

2

Difference between each cylinder

Within ±10%

Loading...

Loading...